Getting the right size grease trap for your kitchen isn't just a suggestion—it's one of the most critical decisions you'll make for your restaurant's plumbing health. It all comes down to a simple process: figure out your kitchen's peak wastewater flow in Gallons Per Minute (GPM), then pick a trap with enough muscle and retention time to properly separate out the fats, oils, and grease (FOG). In a culinary battleground like Las Vegas, nailing this calculation is non-negotiable for staying compliant and keeping your doors open.

Why Sizing Is Everything in the Las Vegas Food Scene

In the high-speed, high-stakes food world of the vibrant city of Las Vegas, where you'll find a diverse array of restaurants that cater to every palate, every single detail affects your bottom line. Think about it—from the massive buffets on the Strip to the cool, local spots in Summerlin, success is built on smooth operations. For any successful kitchen, you'll need essential restaurant equipment like high-performance commercial refrigerators, spacious commercial freezers, and reliable ice machines. But it's the humble grease trap, working silently behind the scenes, that often saves the day.

Choosing the wrong size grease trap is a costly mistake. It’s not just a minor headache; it’s a direct threat to your business. A unit that's too small for your kitchen’s output will fail. That means foul odors that drive customers away, messy drain backups, and even forced shutdowns from the health department. A serious backup can contaminate your entire prep area, putting your food inventory in your commercial freezers and refrigerators at risk.

The Real Cost of a Bad Guess

The consequences, both financially and legally, can be brutal. Clark County and the Southern Nevada Health District have very strict rules about FOG to protect the city's sewer system. If you don't comply, you're looking at heavy fines and being forced to make expensive changes to your setup. When you understand the daily battle of managing FOG and the importance of proper commercial kitchen oil disposal, you see why precise sizing isn't just another box to check.

An undersized grease trap is one of the most common—and costly—mistakes a new restaurant owner can make. It’s not just about passing an initial inspection; it’s about preventing a plumbing catastrophe that could shut you down during a busy Friday night service.

The problem is bigger than just Las Vegas. Undersized traps are the culprit behind a shocking 70% of sewer backups in commercial kitchens worldwide. This single issue costs the global plumbing industry more than $5 billion every year in emergency repairs. On the flip side, a correctly sized trap can capture up to 95% of free-floating FOG, keeping you in the clear with inspectors and your pipes flowing freely.

Ultimately, taking the time to calculate your needs correctly is about more than just playing by the rules. It's about building a resilient business, protecting your expensive equipment, and making sure your restaurant is a good neighbor in the Las Vegas community. This guide will walk you through exactly how to do it right.

Calculating Your Kitchen's Peak Wastewater Flow Rate

Before you can even think about which grease trap to buy, you need one critical number: your kitchen’s peak wastewater flow rate, measured in Gallons Per Minute (GPM). This isn't just some number you pull out of thin air. It’s a calculated figure that represents the absolute maximum amount of water your kitchen could blast down the drains at its busiest moment.

Think about a packed Saturday night on the Strip—every sink, every dishwasher, every piece of equipment running full tilt. That's the scenario you're sizing for. Get this wrong, and your brand-new interceptor will be no match for the rush, leading to messy backups, overflows, and a potential headache with the health department. Nailing this calculation is the foundation for keeping your plumbing—and your entire kitchen—running smoothly.

The Fixture-Based Method for Calculating GPM

The most reliable way to figure out your peak flow rate is by using the fixture-based method. It sounds technical, but it’s pretty straightforward. You're basically just adding up the potential GPM from every sink, dishwasher, and drain that will be connected to your grease trap.

Let's walk through it with a real-world Las Vegas example.

Scenario: A Fremont Street Taco Shop

Imagine you're opening a new, fast-paced taco spot just off Fremont Street. It’s a tight kitchen, but it's going to be busy. You’ve got a few key pieces of equipment that will be generating wastewater:

- A three-compartment pot sink for heavy-duty washing.

- A two-compartment sink for food prep.

- A high-temp commercial dishwasher.

- A floor drain in the middle of the prep area.

To find our peak GPM, we have to look at each of these sources. The sinks are almost always the biggest culprits because they can be filled and dumped in a matter of seconds during the dinner rush.

Measuring and Calculating Sink Flow Rates

The formula for figuring out a sink's GPM output is simple math. You just need a tape measure and a calculator.

First, grab the dimensions of a single sink basin in inches.

- Measure the Dimensions: Get the length, width, and depth of the sink.

- Calculate the Volume: Plug those numbers into this formula: (Length x Width x Depth) / 231 = Volume in Gallons. Why 231? That’s how many cubic inches are in one U.S. gallon.

- Apply the Fill Factor: No one fills a sink to the absolute brim. Codes account for this by assuming sinks are only filled to about 75% capacity. So, multiply your total gallons by 0.75.

- Determine the Drain Rate: This is the most important part. You have to assume the fastest possible drain time. While a sink might take two minutes to drain, you have to plan for the worst-case scenario.

Pro Tip: When sizing a grease trap, always use a one-minute drain time. This assumes a full sink gets dumped instantly, creating the maximum surge your system will ever face. It’s the only way to ensure your trap can handle the pressure.

Putting the Numbers to Work

Let’s run the numbers for our taco shop's three-compartment sink. Each basin is 24 inches long, 24 inches wide, and 14 inches deep.

- Calculate Volume: (24" x 24" x 14") / 231 = 8,064 / 231 = 34.9 gallons per basin.

- Apply Fill Factor: 34.9 gallons x 0.75 = 26.18 gallons of usable volume.

- Determine GPM: Assuming that one-minute "panic drain" scenario, the GPM for just one basin is 26.18 GPM.

Now, it’s unlikely all three basins will be dumped at the exact same second, but for sizing purposes, you have to plan as if they could be. Local codes often have specific rules on how to tally multiple fixtures, but this gives us our starting point.

Factoring in Other Kitchen Equipment

Sinks are just part of the equation. We also have to account for everything else draining into the system. Things like commercial dishwashers and floor drains have pre-set GPM values based on plumbing codes, usually somewhere between 5 to 10 GPM.

Some equipment, like food disposals, can have a major impact on your flow rate and grease load. It's important to know how everything connects. If you're still in the planning phase, thinking about how you manage food scraps can actually simplify your plumbing. You can learn more by checking out our guide on kitchen waste disposals.

For our Fremont Street taco shop, the final tally would look something like this:

- Three-Compartment Sink: 26.18 GPM

- Two-Compartment Prep Sink (18x18x12): 11.2 GPM

- Dishwasher: 6 GPM

- Floor Drain: 5 GPM

Adding up the GPM from every fixture gives you a solid, data-backed number for your kitchen's peak output. This figure is the absolute cornerstone of getting your grease trap sizing right—and making sure your restaurant stays clean, compliant, and operational, even when that Vegas dinner rush hits.

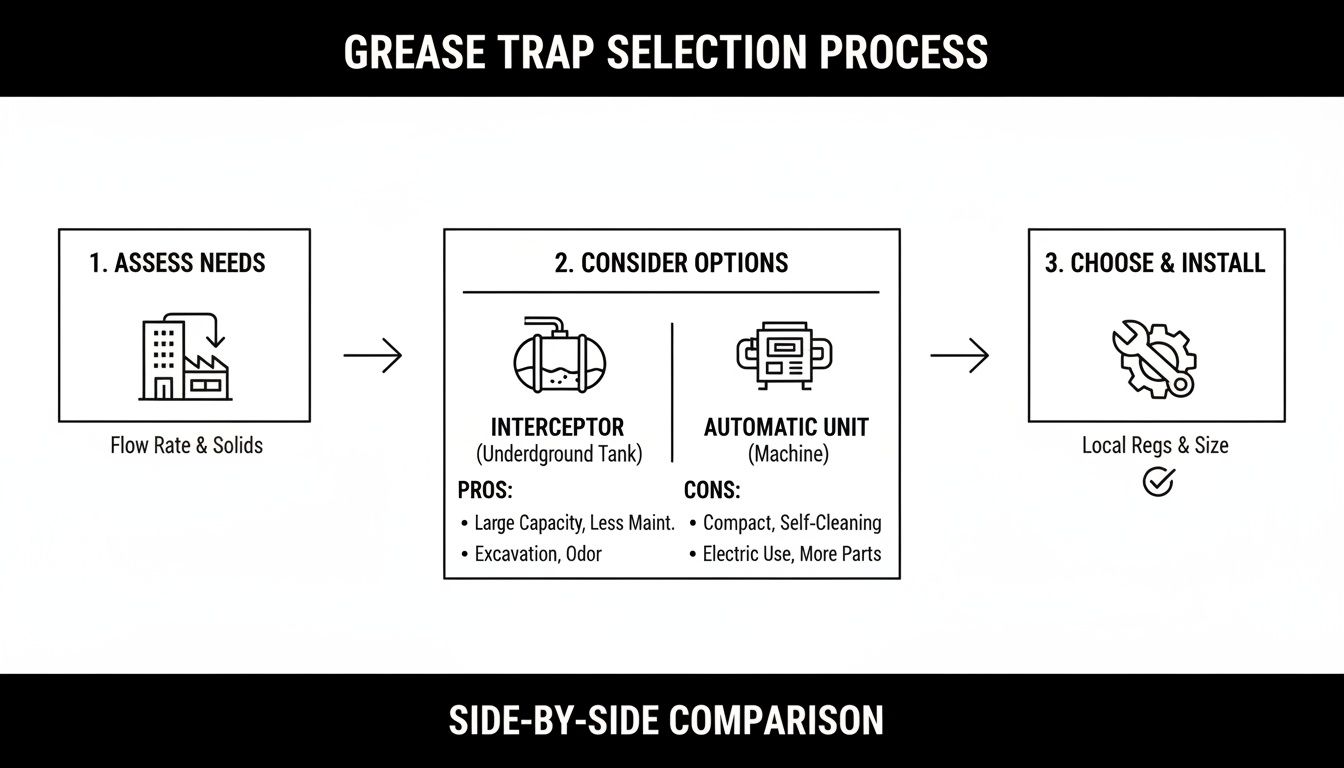

Choosing Between Gravity Interceptors and Automatic Units

Once you've nailed down your peak flow rate, you hit the next fork in the road: what kind of grease trap do you actually need? In a place like Las Vegas, this isn't a one-size-fits-all decision. The setup for a massive Strip casino buffet is worlds away from a lean ghost kitchen pushing out delivery orders.

Your choice really boils down to two main players in the game: the old-school gravity grease interceptors and the more modern Automatic Grease Recovery Units (AGRUs). Getting to know the real-world differences between them is the key to making an investment that won’t give you headaches down the line.

The Old Guard: Gravity Grease Interceptors

Gravity grease interceptors are the big, beefy workhorses of the industry. We're talking about huge tanks, often holding 1,000 gallons or more, usually built from concrete, steel, or fiberglass. Because they're so massive, they almost always live outside and underground, which means you're looking at a serious excavation and plumbing project.

For a sprawling Las Vegas resort kitchen pumping out thousands of meals a day, a gravity interceptor is often the only realistic option. Its sheer size gives it a long retention time, which is just a fancy way of saying the hot, greasy water has plenty of time to sit and cool down. As it cools, the fats, oils, and grease (FOG) naturally float to the top, and solid food scraps sink. Simple physics.

What to expect with a gravity interceptor:

- High Upfront Cost: The tank itself is pricey, but don't forget the installation. Excavation, plumbing, and maybe even concrete work can really drive up that initial bill.

- A Big Footprint: These things take up a lot of outdoor space. That can be a deal-breaker for restaurants in tight urban spots or crowded strip malls.

- Hands-Off for You, Hands-On for Pros: You won’t be cleaning it, but a professional rendering service will need to come pump it out, usually every 30 to 90 days. That’s a recurring operational cost you need to budget for.

The Modern Challenger: Automatic Grease Recovery Units (AGRUs)

On the flip side, you have Automatic Grease Recovery Units. These are much smaller, smarter systems built for indoor use, often tucked right under a three-compartment sink or next to a commercial dishwasher. Instead of just letting gravity do the work, AGRUs use active components like skimmers and heating elements to physically separate and pull the grease out of the water.

This tech is a game-changer for smaller, more efficient kitchens. A trendy café in the Arts District or a specialized food stall in a food hall would be a perfect match for an AGRU’s compact design and high performance. They slide in right alongside your other essential restaurant dishwashing equipment without needing a construction crew.

Where gravity interceptors rely on sheer size and time, AGRUs use technology to get better FOG separation in a much tinier box. This makes them the go-to for kitchens where every square foot counts and efficiency is king.

The market for these automated units is blowing up. Forecasts show the AGU market is on track to fly past USD 3 billion by 2033, and it's easy to see why. They can capture up to 98% of FOG—a huge leap from the 85% you might get from a passive trap. In some cities, this improved performance has already led to a 40% drop in non-compliance fines.

Sure, the initial price tag can be 20-50% higher than a small gravity trap, but they can cut your manual cleaning needs by up to 90%, saving you a ton on maintenance over the long haul. You can dig into more of the data on this industry shift by checking out the market research on automatic grease trap growth.

Ultimately, choosing between a big gravity interceptor and a compact AGU comes down to your kitchen's reality. Think about your daily volume, the space you have to work with, your installation budget, and how you want to handle ongoing maintenance. A high-volume beast might demand a traditional interceptor, but for many independent Las Vegas restaurants, the smart money is on the efficiency and convenience of an automatic unit.

Applying Sizing Formulas and Retention Time Rules

Once you've got your peak flow rate nailed down, it's time to put those numbers to work and figure out the right size for your grease trap. This isn't just a simple math problem. It’s about making sure your system can handle the relentless pace of a Las Vegas kitchen, where essential restaurant equipment for success includes high-powered commercial refrigerators, commercial freezers, and ice machines working around the clock.

The core principle here is retention time. Think of it as the minimum amount of time wastewater needs to "rest" inside the trap. This pause gives the fats, oils, and grease (FOG) a chance to cool down, separate from the water, and float to the top. If the retention time is too short, greasy water just rushes right through the trap and straight into the city sewers, creating the exact plumbing nightmares you’re trying to prevent.

The Math Behind Gravity Interceptors

For the big, in-ground gravity grease interceptors, the sizing calculation is all about volume and time. Local authorities like the Clark County Water Reclamation District (CCWRD) mandate a minimum retention time to guarantee proper FOG separation. While codes can vary, a 30-minute retention time is a solid industry benchmark for most busy kitchens.

The formula itself is pretty straightforward:

Required Interceptor Size (Gallons) = Peak GPM x Retention Time (in minutes)

Let's run through a real-world example. Picture a popular Italian restaurant out in Henderson. After adding up the flow from their prep sinks, a three-compartment sink, and a high-temp commercial dishwasher, they land on a peak flow rate of 40 GPM.

- Calculation: 40 GPM x 30 minutes = 1,200 gallons

So, that restaurant needs a gravity interceptor with at least a 1,200-gallon capacity. This size ensures that even during a slammed Saturday night dinner service, the wastewater gets a full half-hour to cool and separate before it ever leaves the tank.

The flowchart below can help you visualize the decision-making process when choosing between a large interceptor and a smaller automatic unit.

As you can see, while interceptors are the heavyweights for high-volume operations, automatic units offer a compact and highly efficient alternative for smaller kitchens with less space.

Sizing Hydromechanical Units

Now, hydromechanical units—often called Automatic Grease Recovery Units (AGRUs)—are a different beast entirely. They don't just rely on a massive tank for passive separation. Instead, they use a smart system of internal baffles to actively strip FOG from the water. Because they work so efficiently, their required retention time is much, much shorter, often just 2.5 minutes.

Let's consider a downtown Las Vegas coffee shop with a small back-of-house prep area. Their peak flow is a modest 10 GPM.

- Calculation: 10 GPM x 2.5 minutes = 25 gallons

This means a 25-gallon hydromechanical unit would do the job perfectly. These units are rated by the GPM they can handle, so you'd look for a model rated for at least 10 GPM, which typically holds about 20 pounds of grease.

Pro Tip: Always round up to the next available size. If your math points to a 22 GPM unit, go for the 25 GPM model, not the 20 GPM. That little bit of extra capacity is a crucial safety margin you'll be glad to have.

Choosing between these two main types involves different math and considerations. Here's a quick side-by-side look at how their sizing works.

Gravity Interceptor vs. Hydromechanical (Automatic) Unit Sizing

| Factor | Gravity Grease Interceptor | Hydromechanical Grease Trap (AGRU) |

|---|---|---|

| Sizing Basis | Total liquid volume (gallons) | Flow rate (GPM) & grease capacity (lbs) |

| Typical Retention Time | 30 minutes | 2.5 minutes |

| Sizing Formula | Peak GPM x Retention Time | Peak GPM x Retention Time |

| Example Sizing (40 GPM) | 40 GPM x 30 min = 1,200 Gallons | 40 GPM x 2.5 min = 100 Gallons |

This table makes it clear that while the goal is the same—separating FOG—the equipment and the calculations behind it are fundamentally different.

The Grease Production Sizing Method

For some places, especially kitchens that are heavy on equipment like commercial fryers and flat-top griddles, there's another way to look at sizing. The grease production sizing method shifts the focus from water flow to the actual amount of grease being generated.

This method, which is formalized by IAPMO/ANSI standards, uses a formula that factors in things like the number of meals served and the style of food. A simplified version looks like this:

Trap Volume = (Meals per Day x Grease Factor x Retention Factor) / Storage Factor

Each of those "factors" is a value assigned based on the kitchen's specific setup. A fast-food joint cranking out fried chicken will have a much higher grease factor than a small cafe serving salads and sandwiches. This approach gives a more customized and accurate size for high-FOG environments.

These modern sizing guidelines didn't just appear overnight; they evolved from regulations like the U.S. Clean Water Act of 1972. Following these rules isn't just about avoiding fines. Properly sized traps are proven to prevent 80% of U.S. sewer overflows—a problem that has cost an estimated USD 25 billion since 2000. You can dig deeper into the industry impact by checking out this research on the grease traps market.

Whether you're managing a massive buffet on the Strip or a cozy restaurant in a quiet Las Vegas neighborhood, applying the right formula is non-negotiable. It ensures your entire kitchen, including essential equipment like commercial freezers and ice machines, operates in a clean, compliant, and efficient manner.

Getting Right with Las Vegas and Clark County Codes

Running the numbers on your peak flow is a great start, but those calculations don't exist in a bubble. Before you even think about buying a grease trap, you have to get familiar with the specific, non-negotiable rules laid down by the local authorities here in Las Vegas.

For us, that means satisfying two key players: the Clark County Water Reclamation District (CCWRD) and the Southern Nevada Health District (SNHD). These agencies aren't just making friendly suggestions. They have strict mandates that will dictate everything from the minimum size of your interceptor to where you have to put your sample port.

Honestly, trying to sidestep these local codes is a recipe for disaster. I've seen it happen. A failed inspection means your project grinds to a halt, you're looking at hefty fines, and you might even have to rip out brand-new equipment. In a vibrant city like Las Vegas, with its diverse array of restaurants, getting the local requirements right is every bit as important as the sizing math itself.

The Key Mandates You Can't Ignore

National plumbing codes give you a baseline, but Las Vegas and Clark County have their own playbook. It makes sense when you think about it—the sheer number of restaurants here puts an incredible strain on the city's sewer system. Our local codes are built to handle that unique load.

Here’s a rundown of what you’ll almost certainly encounter:

- Minimum Interceptor Size: For most full-service kitchens, the CCWRD often requires a minimum gravity grease interceptor of 750 or 1,000 gallons. That's the starting point, no matter what your flow rate calculations say.

- Location, Location, Location: Big gravity interceptors pretty much always have to go outdoors and underground. It's a non-starter to put them inside. This is both for safety and accessibility, so a pumper truck can service it without dragging equipment through your clean kitchen and past your ice machines.

- The All-Important Sample Port: Your setup must have a dedicated sample port or box. It has to be installed downstream from the interceptor but before the line connects with any other sanitary drains. This gives inspectors a clean, easy-to-access spot to test your wastewater for FOG levels.

These aren't just best practices; they are hard-and-fast rules for getting your plans approved and your restaurant open for business.

Why Your Maintenance Log is So Important

Getting the installation right is only half the battle. The authorities here are extremely serious about ongoing maintenance, and the SNHD requires every food establishment to keep a detailed maintenance log. This isn't just some note you scribble on a calendar—it's an official document that an inspector will ask to see.

A clean, up-to-date maintenance log is your best friend during a health inspection. It’s proof that you’re doing your part to manage FOG, and it can be the difference between a passing grade and a costly citation.

This log has to track every single time the unit is inspected and cleaned. Make sure it includes:

- Date of Service: When was the work done?

- Service Provider: Who did the work? Get the company name and contact info.

- Volume Removed: How much grease and solids were actually pumped out?

- Condition of the Unit: Any notes on the state of the trap, its baffles, and its seals.

If you can't produce this log on demand, you're looking at an immediate penalty. It’s a simple requirement, but it’s a critical piece of the compliance puzzle.

Your Las Vegas Grease Trap Compliance Checklist

To help you keep everything straight and ensure a smooth approval process, run through this checklist as you plan your project.

- Talk to the Authorities First: Before you finalize any designs, get in touch with the CCWRD and SNHD. Ask for their latest FOG program requirements—they can and do change.

- Confirm Minimum Size Rules: Double-check if your restaurant type falls under a mandatory minimum interceptor size that overrules your own calculations.

- Plan Your Site Layout: Make sure your architectural drawings clearly show the outdoor placement for a gravity interceptor and a correctly located, accessible sample port.

- Hire a Plumber Who Knows the Ropes: Don’t just hire any plumber. Find a contractor with proven experience in Clark County commercial kitchens. They’ll know the inspectors and the process.

- Set Up a Maintenance Contract: Line up a reputable grease hauling service before you open. Get your first cleaning on their schedule from day one.

- Start Your Maintenance Log: Have a binder or a digital file set up and ready to go. Log every service call, starting with the very first one.

If you treat these local codes as the foundation of your grease trap strategy, you’ll sidestep some very expensive mistakes and make sure your restaurant is operating in full compliance right from the start.

Installation and Maintenance Best Practices

Getting the grease trap sizing right is the perfect blueprint, but the real test is the installation and the day-to-day upkeep. You can have a perfectly calculated unit, but it’s only as good as where you put it and how you take care of it. In a place like Las Vegas, where kitchens are always running at full tilt, being proactive about these final steps is what stops a minor issue from becoming a full-blown emergency.

A smooth installation really boils down to smart placement. You need to find a spot that’s easy to get to for cleaning but doesn’t throw a wrench in your kitchen’s workflow. Think about it—you need to keep the area around your essential gear, like commercial refrigerators, commercial freezers, and ice machines, totally clear and sanitary.

If you’re installing a big, underground gravity interceptor, this usually means picking a location outside where a pumper truck can easily access it without blocking your patio or parking lot.

Creating a Proactive Maintenance Plan

Once that grease trap is in the ground, you can't just set it and forget it. A detailed maintenance plan isn't just a good idea; it's non-negotiable, especially with Las Vegas health inspectors looking over your shoulder. The core of any good plan is a cleaning schedule that’s based on your kitchen's actual output.

The industry gold standard is the "25% Rule." Put simply, your grease trap needs to be professionally pumped out once the floating FOG and settled solids take up 25% of the trap's total volume. If you wait any longer, its efficiency drops off a cliff, and you’ll start dealing with nasty smells and backups.

To figure out your schedule, start on the conservative side—maybe every 60 days. After a couple of cleanings, you’ll have a much better idea and can adjust. A high-volume steakhouse on the Strip might need monthly service, while a quiet downtown café could get by with quarterly pump-outs.

Recognizing the Signs of a Full Trap

Your own senses are the best first line of defense here. You don’t want to wait for a catastrophic failure. Learn to spot the early warning signs that your trap is getting full and needs a service call.

- Slow Draining Sinks: This is the classic tell. If your three-compartment sink or floor drains are suddenly taking forever to clear, it’s a huge red flag that the trap is full and restricting flow.

- Foul Odors: You’ll know the smell. Rotting grease and food waste have a distinct, unpleasant odor. If you catch whiffs of sour or sewage-like smells near your drains or outside by the interceptor, it’s time to get on the phone.

- Grease in Unexpected Places: Seeing greasy residue in sinks or drains after the trap is a dead giveaway. It means FOG is escaping the unit, and it’s no longer doing its job.

Keeping a meticulous maintenance log isn't just for compliance; it's a vital operational tool. It gives you a historical record to anticipate service needs, budget for the expense, and prove your due diligence to any inspector who walks in.

This focus on cleanliness shouldn't stop at the trap. For total kitchen hygiene, a comprehensive guide to cleaning commercial kitchens is a great resource for any manager. And remember, good maintenance starts at the source. Knowing how to clean stainless steel grill grates properly, for instance, stops excess grease from ever going down the drain. When you tie your grease trap strategy into your overall kitchen hygiene, you’re protecting your entire operation.

Common Questions on Grease Trap Sizing in Las Vegas

Even after you've crunched all the numbers, a few specific questions always seem to pop up. This is especially true for restaurant owners trying to get everything right in the Las Vegas market. We get it. From tricky compliance details to the practicalities of your kitchen layout, you need clear answers to keep your project moving.

Here are some of the most common questions we hear from restaurateurs across the valley about sizing and managing their grease traps.

What Is the Minimum Size Grease Trap Required in Clark County?

This is a big one. While the final size always comes down to your kitchen's specific GPM flow rate calculation, Clark County does set a floor for certain businesses. It's very common to see a 750 or 1,000-gallon gravity interceptor as the absolute mandatory starting point for a full-service restaurant.

But don't just assume that baseline is good enough. You absolutely must run the fixture-based calculations we walked through earlier. Then, you need to talk directly with the Clark County Water Reclamation District (CCWRD) to get the final sign-off for your specific project.

Can I Install a Grease Trap Inside My Kitchen?

It really depends on what kind of unit you're talking about. The smaller, more modern hydromechanical grease traps or an Automatic Grease Recovery Unit (AGRU) are built specifically for indoor installation. They’re designed to be tucked away near the fixtures they serve, like a three-compartment sink or a busy commercial dishwasher.

On the other hand, those big gravity interceptors are a different story. They are almost always installed outdoors and underground. Local Las Vegas and Clark County health codes are very strict about this, and for good reason. They need to be easily accessible for pumper trucks and kept far away from essential restaurant equipment like your commercial refrigerators, commercial freezers, and ice machines to prevent any contamination risk.

How Often Do I Need to Clean My Grease Trap in Las Vegas?

The golden rule here is the "25% Rule," and it's not a suggestion—it's a requirement. The rule is simple: once the gunk inside (the combined fats, oils, grease, and settled solids) fills up 25% of the unit's total liquid capacity, it's time for a professional cleaning.

For any busy Las Vegas restaurant, you're likely looking at a professional pumping service every 30 to 90 days. The Southern Nevada Health District (SNHD) also requires you to keep a detailed logbook of every cleaning and maintenance service. Make sure that log is on-site and ready, because they will ask to see it during a health inspection. It’s your proof that you’re playing by the rules.

Getting your Las Vegas kitchen equipped correctly from day one is the single best thing you can do for your long-term success. From getting the grease trap sizing just right to picking out the perfect commercial freezers and ice machines, every single piece of the puzzle matters. Las Vegas Restaurant Equipment is here to supply the reliable, NSF-certified equipment you need, backed by people who actually know the industry and offer fast, free shipping to the valley.

Explore our full range of commercial kitchen equipment and get a personalized quote at https://lasvegasrestaurantequipment.com.