In a city that runs on world-class hospitality, the non-stop pace of a Las Vegas kitchen demands nothing less than perfection. The true engine of this operation isn't just the celebrity chef; it's the powerful, often-overlooked equipment humming away behind the scenes. This guide is all about the most critical piece of your sanitation puzzle: restaurant dishwashing equipment.

Keeping Your Las Vegas Kitchen Running Smoothly

From the iconic resorts on the Strip to the hidden gems in Fremont East, the vibrant city of Las Vegas boasts a diverse array of restaurants catering to every palate. Success here is all about speed, consistency, and an absolute commitment to quality. Behind every incredible meal and perfectly chilled cocktail is a kitchen built for maximum efficiency, where every single piece of equipment has a job to do.

While the sizzle of the grill gets all the attention, the real unsung hero is the dish pit. If that station gets backed up, it can bring your entire service to a screeching halt. That’s why picking the right restaurant dishwashing equipment isn't just a simple purchase—it’s a strategic move that directly affects your bottom line and your reputation.

The Foundation of a Flawless Operation

Your kitchen is an ecosystem. Every component has to work together perfectly, or the whole thing falls apart. The dishwashing station is the heart of your sanitation, but it can't do its job alone. Essential restaurant equipment needed for success includes:

- Commercial Refrigerators: These workhorses keep everything from delicate microgreens to bulk prep ingredients fresh and safe, whether you're running a fine-dining tasting menu or a high-volume buffet.

- Commercial Freezers: Absolutely vital for long-term storage. They lock in the quality of your prime cuts of meat and pre-made items, making sure you’re always ready for that unexpected dinner rush.

- Ice Machines: In the Las Vegas heat, a reliable supply of ice is non-negotiable. It's in every cocktail, it keeps the seafood display looking pristine, and you can never have enough of it. Check out our guide to commercial ice maker maintenance to keep this crucial machine running strong.

A well-run kitchen is like a finely tuned orchestra. Your commercial dishwasher, refrigerators, and ice machines are the rhythm section—they set the beat for a smooth, flawless service, every single night.

Consider this guide your blueprint for building a tough, efficient, and health-code-ready dishwashing operation. We’ll walk you through the options to help you choose equipment that can take the heat of a sold-out Saturday night, so your team can focus on delivering that unforgettable Las Vegas experience.

Choosing Your Dishwashing Workhorse

Picking out the right piece of restaurant dishwashing equipment isn't a one-size-fits-all decision, especially in a town like Las Vegas where a diverse array of restaurants caters to every palate. The needs of a cozy Arts District coffee shop are a world away from a massive buffet on the Strip.

Think of it like buying a vehicle. You wouldn't try to haul commercial refrigerators in a compact car, and you don't need a semi-truck for a quick grocery run. Each dishwasher is built for a specific job, a certain volume, and a particular kitchen footprint.

The sheer number of plates you're pushing is a huge deal. A busy restaurant can easily see 100 dirty dishes per hour during a dinner rush, making a powerful dishwasher non-negotiable. If you want a deeper dive into market trends, check out the analysis on gminsights.com. This constant flow means your choice of machine directly impacts how smoothly your kitchen runs.

The Compact Sprinter: Undercounter Dishwashers

When you're tight on space, the undercounter dishwasher is your best friend. Picture this machine as a quick, agile delivery van—it’s made to slide into tight spots without giving up professional-grade power.

They fit perfectly under a standard countertop, making them a no-brainer for bars, cafes, or as a second machine in a bigger kitchen just for glassware. While their capacity is smaller, usually washing 20 to 35 racks per hour, they're incredibly efficient. Sticking one at your bar means bartenders can wash and reuse glasses on the fly, keeping the drinks moving and the customers happy without ever leaving their station.

The Reliable Workhorse: Door-Type Dishwashers

The door-type dishwasher, often called a hood-type, is the go-to for most full-service Las Vegas restaurants. This is your reliable, all-purpose cargo van. It’s built to handle a steady, heavy flow of everything from appetizer plates to sauté pans, day in and day out.

It's a standalone station, usually set up between two stainless steel tables—one for dirty dishes coming in, one for clean ones going out. Operation is simple: load a rack, push it in, pull the hood down, and hit start. These machines can wash anywhere from 35 to 80 racks per hour, hitting that sweet spot between size and power. They are the backbone of most kitchens.

Just like a bustling kitchen needs reliable commercial freezers to store inventory, it needs a door-type dishwasher to process the high volume of daily service. It’s the essential middle ground that keeps the entire operation moving forward without interruption.

The Marathon Runner: Conveyor Dishwashers

When you're running a massive operation like a Vegas casino, hotel, or convention center, you need the big guns: a conveyor dishwasher. This isn't a van; it's a freight train. These monsters are built for non-stop, high-capacity cleaning, capable of handling hundreds or even thousands of dishes an hour.

Racks are loaded onto a conveyor belt that pulls them through separate washing, rinsing, and sanitizing chambers. The smaller models start at around 200 racks per hour, but the big ones can do much more. This kind of restaurant dishwashing equipment is a serious investment in money and space, but for high-volume places, nothing else can keep up.

To help you visualize the options, here's a quick comparison to match the right machine to your restaurant's needs.

Commercial Dishwasher Comparison for Las Vegas Restaurants

| Dishwasher Type | Best For | Typical Capacity (Racks/Hour) | Footprint |

|---|---|---|---|

| Undercounter | Small cafes, bars, dedicated glasswashing stations | 20 - 35 | Small (fits under a standard counter) |

| Door/Hood Type | Full-service restaurants, diners, most kitchens | 35 - 80 | Medium (requires a dedicated station) |

| Conveyor | Casinos, hotels, hospitals, high-volume cafeterias | 200+ | Large (requires significant dedicated space) |

Choosing the right type is the first step. The undercounter is perfect for targeted, low-volume needs, the door-type is the all-around champion for most restaurants, and the conveyor is the only choice for truly massive operations.

Alright, once you've zeroed in on the right type of restaurant dishwashing equipment for your kitchen, it's time to look under the hood. This is where the real magic happens. Getting a handle on the technical specs is the difference between buying a machine that just "works" and investing in one that's an absolute beast during a packed Saturday night service. These numbers aren't just industry fluff; they're the DNA of your kitchen's sanitation powerhouse.

Think of these specs as your dishwasher's vital signs. A chef knows the exact temperature for a perfect medium-rare steak, and you need to know these metrics to keep your dish pit running at peak health. This is how you move past the price tag and find a machine that actually fuels your operation instead of holding it back.

And let's be clear, this is a big deal. In the world of commercial kitchens, restaurants are the undisputed kings, driving a massive 47% of the revenue in the commercial dishwasher market. The big guns—like rack conveyors that can chew through over 1,000 dishes an hour—are taking off for a reason. You can dive deeper into the numbers with this market analysis from Future Market Insights, but the takeaway is simple: high-performance gear is critical for survival.

Calculating Your True Capacity Needs

The first spec you'll always see is racks per hour. This number is the machine's top speed on a perfect day. But what you really need to figure out is your kitchen's actual peak demand.

Start by picturing your busiest service—probably a sold-out weekend night. Tally up your total seats, how many times you flip those tables, and how many plates, glasses, and forks each guest goes through. A fine-dining spot with a six-course tasting menu is going to generate a mountain of dishes compared to a quick-service cafe.

Here's a classic mistake we see all the time: underestimating peak demand. A machine that can barely keep up on a slow Tuesday is going to create an absolute disaster when you're fully booked. It'll bring your entire service to a grinding, painful halt.

The Great Debate: High-Temp vs. Low-Temp Sanitation

Sanitizing is the whole point, right? This gets done in one of two ways, and each has its own pros and cons, especially for a demanding Las Vegas operation.

-

High-Temperature Dishwashers: These machines are the workhorses. They use a booster heater to get the final rinse water screaming hot—all the way up to 180°F, the magic number for killing bacteria on contact. The intense heat makes dishes flash-dry almost instantly. That means no more manual towel drying, which saves labor and cuts down on the risk of someone re-contaminating a clean plate with a dirty towel. They cost more upfront and might need a pricey vent hood, but you won't be paying for chemical sanitizers month after month.

-

Low-Temperature Dishwashers: These models are a bit different. They run at cooler temperatures (120-140°F) and rely on chemical sanitizers—like chlorine or iodine—to do the dirty work in the final rinse. They're usually cheaper to buy and install, and they sip less energy. The catch? You have a recurring chemical bill, and the dishes take longer to air-dry. If you're tight on space, that slow dry time can really jam up your workflow.

Compliance and Conservation

For any restaurant dishwashing equipment in Las Vegas, two final specs are totally non-negotiable: compliance and efficiency.

First, NSF certification is a must. Period. The Southern Nevada Health District mandates that all your food service equipment has that NSF seal of approval, which is your guarantee that it meets tough public health and safety standards. An inspector will look for this mark, and not having it can lead to fines or even getting shut down.

Second, think about your utility bills. We're in the desert, and water and energy aren't cheap. Keep an eye out for ENERGY STAR® certified models. These machines can be up to 40% more energy-efficient and use a lot less water with every single cycle. Not only does this save you real money every month, but it also shows you're committed to sustainability—something a lot of your customers actually care about.

Designing an Efficient Dish Pit Workflow

A brand new, state-of-the-art piece of restaurant dishwashing equipment is an amazing thing, but it’s only as good as the system you build around it. It's like having a race car engine without a chassis or wheels—all that power and potential goes nowhere without a smart, efficient workflow. Designing your dish pit is all about turning that potential chaos into a smooth, predictable process, which is absolutely critical in the non-stop, high-stakes world of a Las Vegas kitchen.

The name of the game is creating a logical, one-way street for dirty dishes. This simple concept prevents cross-contamination and crushes the bottlenecks that can bring a kitchen to a dead stop during a dinner rush. The most effective layout I’ve seen time and time again is the classic three-zone system, a model that works just as well in a sprawling Strip resort as it does in a cozy downtown bistro.

The Three-Zone System for Maximum Throughput

This battle-tested method breaks down the entire dishwashing process into three distinct, can't-miss stages. Each zone has a single job, making sure every plate, glass, and fork moves forward without ever backtracking.

-

The Soiled Zone (The Landing Area): This is where it all starts. Servers and bussers drop their loads of dirty dishes at a landing table. This spot absolutely must have a pre-rinse sprayer to blast off the heavy food scraps before anything hits the dishwasher. Think of it as triage—scraping and spraying here is what keeps food gunk from clogging up your machine and guarantees a much better clean.

-

The Wash Zone (The Dishwasher Station): This is the heart of the whole operation, where your restaurant dishwashing equipment does its magic. Whether you’ve got a door-type or a massive conveyor system, this station has to be an easy hand-off from the soiled zone. Racks get loaded, sent through the cycle, and come out sanitized and ready for the final step.

-

The Clean Zone (Drying and Staging): Once the cycle is done, the hot, clean racks are moved to a completely separate, clean drainboard or table. This zone is strictly for air-drying. Wiping dishes with a towel is a huge no-no; it can reintroduce bacteria and undo everything the machine just did. You need plenty of space here for racks to dry and for your team to safely stack and store the clean wares, ready to head back out to the front lines.

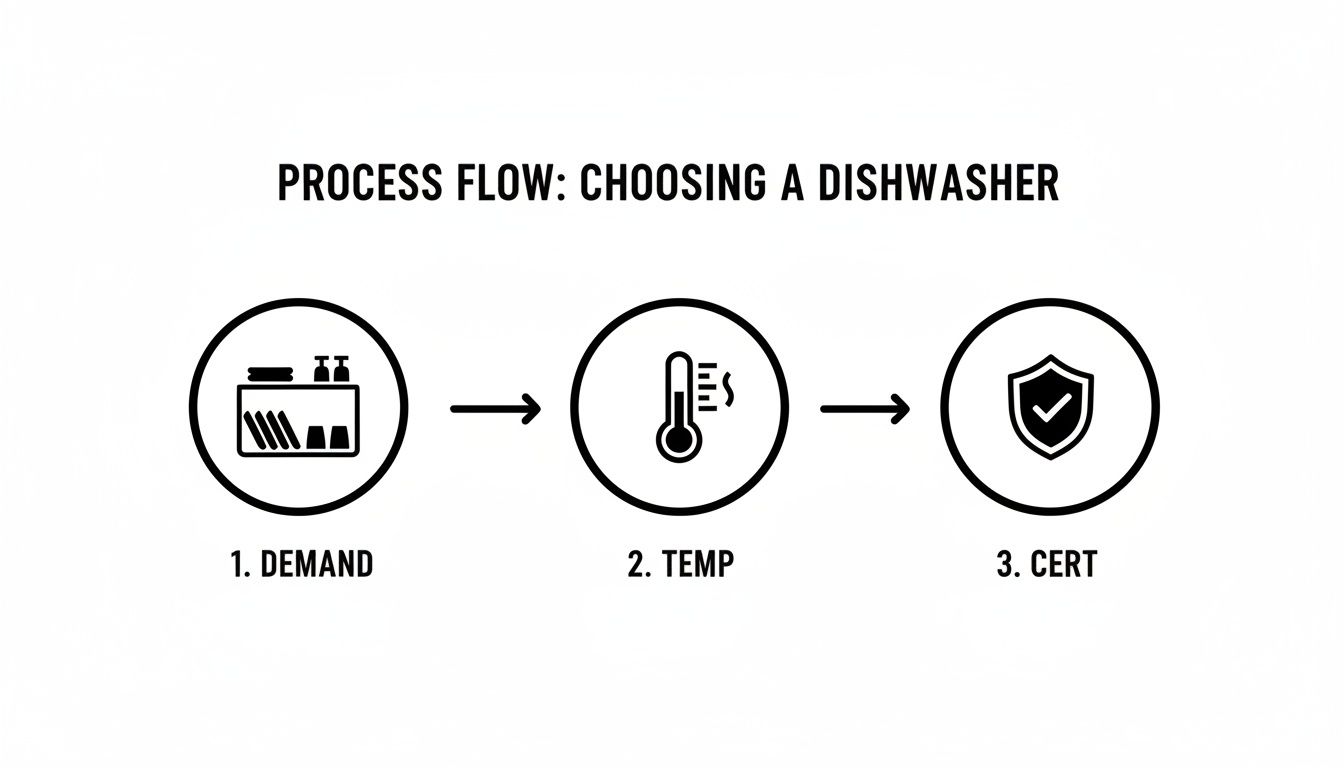

To make the right call for your wash zone, this quick visual guide breaks down the most important decision points.

This flow chart nails the critical first steps for outfitting your wash zone: figuring out your demand, picking the right temperature for the job, and making sure your machine has the right certifications.

Ergonomics and Layout Strategy

An efficient workflow isn't just about the path the dishes take; it's about the people doing the work. A good, ergonomic design reduces staff fatigue, minimizes physical strain, and sends productivity through the roof. Simply placing the soiled and clean tables at a comfortable working height can save your team from constant bending and reaching.

A well-designed dish pit respects the physical demands of the job. By minimizing unnecessary steps and awkward movements, you not only speed up the process but also create a safer and more sustainable work environment for your team.

The flow has to be seamless. A straight right-to-left or left-to-right setup ensures no one is tripping over each other or doubling back. The pre-rinse sprayer should be right next to the dishwasher's entrance, and the clean table should be right at the exit.

Getting this layout right starts with having the right commercial kitchen sinks and tables. To build this perfect flow, you’ll need to explore the different three-compartment and utility sinks that really form the backbone of any killer dish pit. When you plan the space with logic and your people in mind, every movement has a purpose, keeping your Las Vegas kitchen running at absolute peak performance.

Installation and Maintenance Best Practices

So, your new piece of restaurant dishwashing equipment has finally arrived. But don't pop the champagne just yet—the real work is just beginning. Getting the installation right is the foundation for a decade or more of reliable service, and a solid maintenance routine is the best insurance policy you can get for this major investment.

Cutting corners here is like buying a Ferrari and then never changing the oil. You're just asking for an expensive, totally preventable breakdown, probably right in the middle of a chaotic Saturday night dinner rush on the Strip.

Professional installation isn't just a friendly suggestion; it’s absolutely critical for performance and safety. This isn't your home dishwasher you can just slide into place. We're talking about complex connections that have to meet strict Las Vegas and Clark County codes.

- Plumbing: You need the right water lines to hit the required pressure and temperature. Even more important are the drainage and air gaps, which prevent contaminated water from backflowing into your clean supply—a massive health code violation waiting to happen.

- Electrical: Commercial dishwashers, especially high-temp models with booster heaters, are power-hungry beasts. They demand dedicated circuits installed by a licensed electrician to stop overloads and prevent a serious fire risk.

- Ventilation: High-temp machines pump out a ton of steam. Proper ventilation, usually a commercial vent hood, is a must-have to control the heat and humidity in your kitchen, protecting your staff, your walls, and your other equipment from moisture damage.

The Power of Proactive Maintenance

Once your machine is installed and humming along, its future is in your hands. A simple, consistent maintenance checklist can head off 90% of common equipment failures. Think of it as a daily health checkup for the heart of your BOH sanitation. A machine that’s looked after can easily last up to 20 years, which makes a few minutes of daily upkeep an incredibly smart investment.

This proactive mindset is key, especially in today's booming food service world. The global market for commercial dishwashers hit a staggering USD 3.5 billion in 2023, and with the number of U.S. restaurants growing to 704,593, the pressure on this equipment has never been higher. This is why protecting your investment is so important.

Your Daily, Weekly, and Monthly Checklist

The best checklist is one your team will actually use. Keep it simple, clear, and make it a non-negotiable part of your opening and closing procedures.

Daily Tasks (After Every Single Shift):

- Drain and Clean: Empty the wash tank completely. Never, ever let dirty water sit overnight. It’s a breeding ground for bacteria and creates nasty odors.

- Remove and Inspect: Pull out the filter screens and spray arms. Clear out every bit of food debris. A clogged nozzle is the #1 reason for streaky, dirty dishes.

- Wipe Down Interior: Give the inside of the machine a thorough wipe-down to stop grime and scale from building up.

- Let It Breathe: Prop the dishwasher door open overnight. This lets the inside dry completely, which prevents mold and mildew from taking hold.

"Your dishwasher is not a garbage disposal. The single most important maintenance step is ensuring your team diligently pre-scraps and pre-rinses every dish. This prevents clogs, protects the pump, and ensures a perfect clean every time."

Weekly Tasks:

- De-lime the Machine: This is huge, especially with Las Vegas's notoriously hard water. Mineral buildup (scale) will kill your heating elements and block spray jets. Run a de-liming cycle with a good commercial-grade solution.

- Check Chemical Levels: If you're running a low-temp machine, make sure your sanitizer and rinse-aid containers are full and that the pumps are dispensing correctly.

Monthly Tasks:

- Inspect Hoses and Connections: Take a close look at the water and drain lines. You're searching for any signs of leaks, cracks, or general wear and tear.

- Calibrate Temperatures: Grab a waterproof thermometer and check that your wash and final rinse cycles are hitting their target temperatures. This is crucial for proper sanitation.

Sticking to this schedule will keep your restaurant dishwashing equipment running like a top and even helps protect your other big-ticket items. For instance, keeping all that steam and humidity under control is vital for your walk-ins and reach-ins. You can learn more about this in our guide to energy-efficient commercial refrigeration. At the end of the day, these simple habits extend the life of your machine, lower your utility bills, and guarantee every single plate that goes out to a customer is perfectly clean and safe.

Your Partner for Kitchen Success in Las Vegas

Look, navigating the world of restaurant dishwashing equipment is a big deal when you're trying to make it in Las Vegas. This is a city where world-class dining meets non-stop demand, and every successful kitchen—from the mega-resorts on the Strip to your favorite local spot—is built on a foundation of powerful, reliable gear. Figuring out what you need is the first step, but the real edge comes from teaming up with a local expert who just gets the pressure of this town.

In a city that truly never sleeps, having the right equipment is non-negotiable. And that goes way beyond the dish pit. It’s about the entire ecosystem of essential restaurant equipment needed for success.

More Than Just Dishwashers

An efficient kitchen isn't just a collection of machines; it's a system where everything works together. Your dishwasher might be the star of the show when it comes to sanitation, but it needs a solid supporting cast to keep things running smoothly.

- Commercial Refrigerators: These are the heart of your kitchen. In our desert heat, they’re working overtime to keep everything from prime cuts of steak to delicate produce perfectly fresh.

- Commercial Freezers: These are essential for serious inventory. They give you the buying power to stock up and the depth to handle those unexpected rushes without breaking a sweat.

- Ice Machines: In Vegas, a good ice machine isn't a luxury—it's a lifeline. It's what's behind every perfect cocktail and what keeps your food displays safe and looking great.

Choosing a supplier who understands this whole picture is critical. A partner who's actually based here in Las Vegas isn't just selling you a box; they're giving you a strategic advantage dialed in to the local pace.

For a Las Vegas restaurant, downtime simply isn't an option. Partnering with a local equipment supplier means getting faster solutions, tapping into deeper market knowledge, and having someone in your corner who’s committed to keeping your kitchen at full throttle, no matter what.

Working with a dedicated Las Vegas supplier gives you real, tangible benefits that you'll feel on your bottom line. We're talking fast delivery—often within one to two business days—to get you up and running quicker. That’s backed by solid warranty support from people who understand that when a machine goes down, you need help now. On top of that, flexible financing options are available to help new restaurants get off the ground or established spots expand without tying up a ton of cash.

You now know how to size up your needs, understand the tech, and plan for the long haul. The next move is to connect with our team. We want you to take all this knowledge and let us help you build the perfect setup for your place. A quick chat can make sure you get the exact restaurant dishwashing equipment and supporting gear you need to kill it in the competitive Las Vegas scene.

Your Top Commercial Dishwasher Questions, Answered

Even when you think you've got it all figured out, dropping serious cash on a piece of restaurant dishwashing equipment is going to bring up some questions. It's just part of the process. The good news is, whether you're running a high-volume spot on the Strip or a neighborhood cafe, most owners run into the same handful of challenges.

Let's cut through the noise and tackle the most common questions we get from Las Vegas restaurant operators. Getting straight answers here is the key to a smart buy that keeps your back-of-house from grinding to a halt.

What Is the Difference Between a High-Temp and a Low-Temp Commercial Dishwasher?

This is probably the first big decision you'll make. Think of a high-temp dishwasher as a pure brute-force machine. It uses a built-in booster heater to superheat the final rinse water to a blistering 180°F or more. That intense heat sanitizes everything on contact and causes the dishes to "flash-dry" almost the second they come out of the machine, which is a huge time-saver for your crew.

A low-temp dishwasher, on the other hand, works smarter, not hotter. It relies on chemical sanitizers (usually chlorine) to do the bacteria-killing in water that's much cooler, around 120°F to 140°F. You'll save a ton on energy since you're not constantly heating that much water, but you'll have a recurring budget line for the chemicals. It really boils down to whether you'd rather pay more upfront for installation and energy, or pay less upfront but have an ongoing chemical cost.

How Do I Know What Size Dishwasher My Las Vegas Restaurant Needs?

This is critical, and you have to think about your absolute worst-case scenario. Picture a packed Saturday night, every table is full, and the waitlist is an hour long. That's the moment your dishwasher needs to handle.

To figure out the right size, you need to calculate your peak demand. Look at:

- Your total seat count: How many people can you serve at once?

- Table turnover: During that busiest hour, how many times does each table get reseated?

- What's on the menu: A place serving multi-course tasting menus is going to generate a mountain of dishes compared to a cafe slinging sandwiches and coffee.

Running these numbers will give you the "racks per hour" capacity you absolutely must have. Guessing too low here is a recipe for disaster, creating a bottleneck in the dish pit that can bring your entire service crashing down.

Why Is NSF Certification Important for My Commercial Dishwasher?

Let me be direct: in Las Vegas, NSF certification isn't a "nice-to-have." It's a non-negotiable requirement to get the green light from the Southern Nevada Health District.

Think of the NSF mark as a passport for your equipment. It's the official guarantee that your dishwasher is designed for food safety, can be easily cleaned, and won't harbor harmful bacteria. Without it, you risk fines or even a forced closure.

Health inspectors are trained to look for that little blue sticker on everything from your commercial refrigerators to your ice machines. Trying to operate without it is playing with fire, which makes it an absolute must-have feature for any piece of restaurant dishwashing equipment you're considering.

Ready to find the perfect dishwashing solution for your Las Vegas kitchen? The team at Las Vegas Restaurant Equipment is here to help you navigate the options with expert advice, fast local delivery, and flexible financing. Explore our full range of commercial kitchen essentials at https://lasvegasrestaurantequipment.com and build an operation that's ready for anything.