In a city that runs 24/7, frozen beverage dispensers are so much more than a fun novelty—they're high-margin workhorses. The vibrant city of Las Vegas is home to a diverse array of restaurants catering to every palate, from fine dining on the Strip to cozy neighborhood cafes. Think about it: from signature frozen cocktails in a casino lounge to a much-needed slushie in a packed Henderson eatery, these machines are pure profit generators, especially when the summer heat really kicks in. This guide is your complete roadmap to making a smart investment that keeps your customers happy and your cash register ringing.

Turning Up the Profit in the Las Vegas Heat

In the wild and competitive Las Vegas food scene, success is all about standing out while keeping your operations tight. Every restaurant here, from the big resorts to the neighborhood spots, has one thing in common: they need reliable, high-performance equipment to survive. A well-equipped kitchen isn't just nice to have; it's the backbone of your entire business. Success in this vibrant culinary landscape requires the right tools.

At the very core, a few pieces of essential restaurant equipment are non-negotiable for success. You absolutely need solid commercial refrigerators and commercial freezers to protect your inventory and keep ingredients safe. In this climate, a powerful ice machine isn't a luxury; it's essential for keeping drinks perfectly cold. Right alongside these staples, a frozen beverage dispenser gives you a golden opportunity to boost profits with almost no extra labor.

Why Frozen Drinks Are a Vegas Essential

Frozen drinks sell an experience, not just a product. They’re a visual treat that perfectly matches the high-energy vibe of Las Vegas. For you, the operator, the deal is even sweeter: the profit margins are incredible. The cost of syrup and water is pennies on the dollar, which means a huge markup on every single cup you sell.

In a market where every dollar counts, a frozen drink program offers one of the best returns on investment you can get. It’s a dead-simple way to bump up your check averages and give customers something they love, turning a single machine into a steady stream of income.

This guide will walk you through everything you need to know. We’ll get into the different types of machines, what features matter most for our desert climate, how to keep them clean and running, and smart ways to buy. Our goal is to give you the know-how to pick a machine that becomes a star player in your equipment lineup—just as vital as your trusty walk-in cooler. By the time we're done, you'll see exactly how to turn frozen treats into a serious business advantage.

Machine Matchup for Your Las Vegas Business

Picking the right frozen drink machine is like choosing the right car. A little sports car is great for a solo cruise, but you wouldn’t use it to haul lumber. Same idea here. What works for a small coffee shop won’t cut it for a high-volume casino bar, especially in a city that never stops. Let's dig into the main players and figure out what your business really needs.

You'll mainly run into two types: standard granita machines and frozen carbonated beverage (FCB) dispensers.

Think of granita machines as your all-purpose workhorse. They’re perfect for churning out everything from classic margaritas and frosé to kid-friendly slushies. They take a pre-mixed liquid and freeze it down into that perfect icy consistency.

FCB dispensers, on the other hand, are the specialists. They hook up to a CO2 line to create those fizzy, slushy drinks you see at convenience stores and movie theaters. While you won't typically use them for cocktails, they're absolute champs at slinging a high volume of non-alcoholic drinks. For most Las Vegas restaurants and bars, the flexibility of a granita machine is the way to go.

Hopper Capacity and Output

The first thing you notice on a granita machine are the clear bowls on top—the hoppers. They're more than just a display case for your colorful concoctions; they dictate how much you can serve and how many flavors you can offer.

- Single-Bowl Models: Perfect for a small cafe or a bar that just wants to add one signature frozen cocktail to the menu. It's a low-risk way to test the waters with a new frozen drink without a huge commitment.

- Double-Bowl Models: This is the sweet spot for most restaurants and bars. A double-bowl setup lets you keep a crowd-pleaser like a lime margarita running constantly while offering a fun, rotating special—maybe a frozen peach bellini or a seasonal sangria slush.

- Triple-Bowl Models: These are the heavy hitters. You'll find these beasts in busy casino bars, massive family restaurants, and any spot where demand is through the roof. They give you maximum variety and ensure you're never caught empty-handed during a weekend rush.

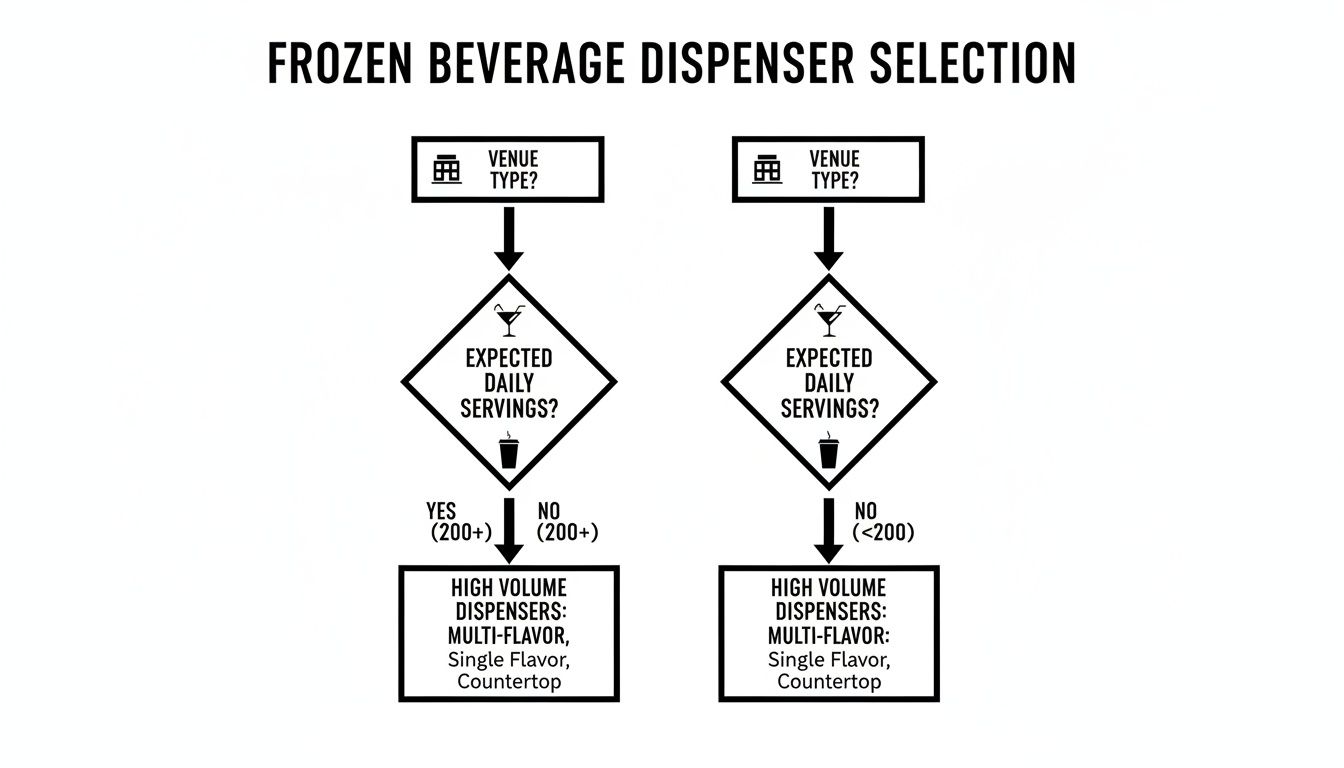

This simple chart helps visualize how to match the machine to the madness of your daily service.

As you can see, the more people you serve, the more you need multiple bowls and a powerful cooling system to keep the drinks flowing.

Critical Cooling Systems for the Vegas Climate

In the brutal Las Vegas heat, how your machine cools itself down isn't just a feature—it's everything. A machine that overheats is a machine that’s costing you money. You’ve got two choices: air-cooled or water-cooled. Your kitchen's environment will make the decision for you.

An air-cooled unit works a lot like a window AC unit. It sucks in the surrounding air to cool down its internal components, then blows the hot air out. They're usually cheaper and simpler to install, but they have one massive weakness: they need room to breathe. Shove one into a cramped, hot kitchen with no airflow, and you're just asking for that compressor to burn out.

The biggest rookie mistake I see is operators cramming an air-cooled machine into a tight corner. In a Vegas kitchen hitting 100°F, that machine is suffocating. Your drinks will take forever to freeze, and you'll be calling for a pricey repair before you know it.

A water-cooled unit, however, is more like a car's radiator. It uses water to carry heat away, making it completely independent of the hot air in your kitchen. This is the undisputed champion for tight, sweltering kitchens. They cost more upfront and need a water line and drain, but their reliability in our extreme climate is worth every penny. For a busy spot on the Strip, a water-cooled model isn't just a good idea; it's a smart investment.

As you consider your options, it helps to think about your whole beverage station. Getting a handle on understanding bar refrigerator sizes and capacity can help you build a more efficient and cohesive setup.

To make things even clearer, we've put together a quick guide to help you find the perfect match for your business.

Machine Matchup for Your Las Vegas Business

Use this table to find the perfect frozen beverage dispenser for your venue's unique needs, from a local cafe to a high-traffic Strip resort.

| Venue Type | Recommended Machine Type | Ideal Hopper Setup | Key Climate Consideration |

|---|---|---|---|

| Small Cafe / Food Truck | Standard Granita | Single-Bowl or Double-Bowl | Air-cooled is fine with proper 6-inch ventilation clearance. |

| Neighborhood Restaurant | Standard Granita | Double-Bowl | Air-cooled works, but consider water-cooled if in a hot kitchen. |

| High-Volume Bar / Pub | Standard Granita | Double-Bowl or Triple-Bowl | Water-cooled is highly recommended for reliability. |

| Casino / Resort | Standard Granita | Triple-Bowl (multiple units) | Water-cooled is essential for non-stop, high-demand operation. |

| Convenience Store | FCB Dispenser | Multi-Flavor (integrated unit) | Air-cooled is standard, placed in the front-of-house area. |

No matter your business size, there's a machine built to handle the heat and the crowds. The key is being honest about your space and your volume before you buy.

Proper Installation in a Commercial Kitchen

You’ve picked out the perfect frozen beverage dispenser. Great. But what you do next is arguably the most critical step for its long-term health and performance. Getting the installation right sets you up for success, helping you dodge the kind of expensive, frustrating headaches that can shut down your frozen drink program completely. In the high-stakes, high-heat world of a Las Vegas kitchen, nailing this from day one isn’t a suggestion—it’s a requirement.

Think of your new machine as a high-performance athlete; it needs the right environment to do its job. It all starts with placement. The unit absolutely must sit on a sturdy, level countertop that can handle its full weight. A wobbly or slanted surface is just asking for trouble—it can cause uneven freezing, strain the motor, and eventually lead to leaks.

This whole process is a small but vital piece of a much larger puzzle: kitchen efficiency. If you want to take a deeper look at creating a workspace that really flows, check out our guide on designing a restaurant kitchen. It’s packed with insights that can help streamline your entire operation.

Giving Your Machine Room to Breathe

The single biggest mistake we see with these installations is suffocation. I’m not kidding. For any air-cooled model, proper ventilation is completely non-negotiable. These machines cool themselves by pulling in ambient air to cool down the compressor and condenser coils, then pushing out hot air. If you box them in, they’re basically trying to breathe through a plastic bag.

To keep that from happening, you have to follow the manufacturer's clearance specs. They usually call for at least 6-8 inches of open space on all vented sides. Shoving an air-cooled unit into a tight cabinet or right up against a wall will trap all that hot air, forcing the compressor to work itself to death. In a Vegas kitchen that can easily top 100°F, that’s a recipe for a very fast, very expensive failure.

Powering Up and Plumbing In

Frozen beverage dispensers are powerful pieces of equipment, and they have very specific utility needs. You can’t just plug one into the nearest outlet and hope for the best. A mismatched electrical setup is a serious fire hazard and can fry the machine’s electronics in an instant.

Before you even think about plugging it in, confirm these details:

- Voltage: Does it need a standard 120V outlet, or are you looking at a more powerful 220V/240V circuit?

- Amperage: Check the amp draw. This machine needs its own dedicated circuit that can handle the load, especially during that initial freeze-down when it’s pulling maximum power.

- Plug Type: Look at the plug itself (is it a NEMA 5-15P, 6-20P, etc.?) and make sure you have the right receptacle ready to go.

Always bring in a certified electrician to install a new, dedicated outlet if you need one. Trying to run this on the same circuit as a commercial fridge or an ice machine is a guaranteed way to cause electrical issues and kill your service.

If you have a water-cooled or auto-fill model, plumbing is the next critical step. You’ll need a cold water line with a nearby shut-off valve for easy access. You'll also need a drain line for condensation and wastewater, making sure it’s properly routed to a floor drain to keep your floors dry and safe.

Optimizing Your Counter Layout for Workflow

Finally, think about your people. The best installation is one that makes the machine easy for your staff to use, refill, and clean. Put it somewhere that makes sense for your workflow, maybe near your other beverage stations but with enough elbow room to avoid traffic jams.

Your team should be able to get to the hoppers for refills without having to grab a step stool or lean over a hot flattop. And simple daily tasks, like emptying the drip tray and wiping down the unit, should be completely unobstructed. A well-placed machine doesn't just run better—it becomes a seamless part of your team's routine, ensuring it stays a money-maker instead of an operational nightmare.

Essential Maintenance and Cleaning Protocols

Once your frozen beverage dispenser is installed, it’s ready to start making you money. But its long-term success really boils down to one thing: consistent, thorough maintenance. A clean machine is a reliable one, pumping out safe, delicious drinks that keep your customers coming back. A neglected one, on the other hand, quickly turns into a health hazard and a prime candidate for a costly breakdown.

This isn’t just about being a good operator; it’s about staying compliant. The Southern Nevada Health District (SNHD) has very strict standards for food equipment sanitation, and your dispenser is definitely on their radar. Sticking to a clear maintenance schedule is the best way to keep them happy, protect your guests, and get the most life out of your valuable equipment.

Being proactive is a huge deal in a competitive market like Las Vegas, where your reputation is everything. This commitment to quality is what’s fueling growth across the industry. The global market for these machines, valued at around USD 2.0 billion in 2025, is expected to explode to USD 3.8 billion by 2035. That growth is a direct reflection of the massive demand for frozen drinks in high-volume spots like the restaurants and bars that define the Vegas scene.

Your Daily Maintenance Checklist

Simple daily habits are your first line of defense against bacteria and performance hiccups. These quick tasks should only take a few minutes at the beginning or end of a shift and need to become an automatic part of your team's routine.

- Wipe Down Exterior Surfaces: Grab a food-safe sanitizer and give the whole outside of the machine a good cleaning, paying close attention to the dispenser handles and splash guards.

- Empty and Sanitize Drip Trays: Drip trays are a magnet for mold and bacteria. Pull them out, empty them, wash with soap and water, and then sanitize them before putting them back.

- Clean Dispensing Nozzles: Carefully clean the spigots where the drink actually comes out. A small brush is perfect for getting rid of any sticky residue.

These little steps stop minor messes from becoming major headaches and keep your machine looking clean and professional for your customers.

Weekly and Bi-Weekly Deep Cleaning

While daily wipe-downs are essential, you need a more intense cleaning to keep the inside of the machine sanitary and running right. How often you do this—usually every 7 to 14 days—really depends on your product and how busy you are. Dairy-based mixes or high-sugar syrups will need more frequent attention.

This process means taking the machine apart:

- Drain and Discard: Empty out any leftover product from the hoppers. Never, ever reuse old product.

- Rinse the System: Fill the hoppers with warm water and run it through the machine. This flushes out any gunk left behind.

- Disassemble Components: Following the manufacturer's guide, carefully take out the hoppers, augers (those are the spiral mixers), seals, and gaskets.

- Wash and Sanitize: Wash all these parts in a three-compartment sink using a food-safe detergent, then rinse them and let them soak in a sanitizing solution.

- Lubricate Seals: Before you put it all back together, apply a food-grade lubricant to all the seals and O-rings. This is a critical step to prevent leaks and cut down on wear and tear.

A dry, unlubricated seal is one of the top reasons for leaks and motor strain. Skipping this one little step can lead to a sticky disaster and an expensive service call. It's like running an engine without oil—sooner or later, something's going to give.

Monthly Mechanical and Safety Checks

Once a month, take a few minutes to look over the machine's core components. This quick preventative check can help you catch potential problems before they shut you down during a rush.

- Inspect Condenser Coils: Just like a commercial fridge or ice machine, your dispenser's condenser coils can get clogged with dust and grease, especially in a busy kitchen. A dirty coil makes the compressor work way too hard, which leads to overheating and failure. Gently clean the coils with a stiff brush or a vacuum.

- Check for Leaks: Do a quick visual inspection for any signs of product or water leaking around the seals, gaskets, or internal connections.

- Listen for Strange Noises: Pay attention to how the machine sounds. If you hear any new grinding, squealing, or rattling, it could be a sign of a motor or gearbox issue that needs to be checked out immediately.

A lot of the principles for maintaining your frozen drink machine apply to other kitchen equipment, too. For a deeper dive that might help with your other cooling units, take a look at our guide on commercial ice maker maintenance.

Understanding NSF and ETL Certifications

When you see an NSF (National Sanitation Foundation) or ETL (Intertek) mark on your dispenser, it's not just a sticker. It’s your guarantee that the machine has been put through the wringer and certified to meet public health and safety standards.

These certifications mean the unit is designed to be cleaned easily and completely, with no weird crevices where bacteria can build up. For any business in Las Vegas, using certified equipment is a non-negotiable part of passing health inspections and showing you’re serious about food safety. It ensures your machine is built to handle the chaos of a commercial kitchen, protecting both your customers and your business.

Calculating Your Costs and Boosting Your Return on Investment

Buying a new frozen beverage machine is a big move. To make sure it’s the right one for your Las Vegas spot, you can't just look at the price tag. You’ve got to get a handle on the total cost of ownership—that’s the full financial picture that really tells you if you're going to make money.

The initial price is just the starting line. You need to think about what it costs to keep the machine humming day in and day out. We're talking about the electricity for the compressor, the price of your syrups and mixes, and the little things like cleaning supplies, seals, and lubricants. Getting your head around understanding profit and loss statements for your vending business is a huge help here; it’s essential for tracking these costs accurately.

Calculating Your True Cost Per Serving

So, how do you figure out your break-even point and get the best return on your investment? It all starts with knowing exactly what one drink costs you to make.

It's a pretty simple formula:

(Cost of Mix + Cost of Water/Ice + Cost of Cup/Lid/Straw) / Servings Per Batch = Cost Per Serving

Let's run some numbers. Picture a busy bar just off the Strip. A half-gallon jug of good margarita mix runs you $15 and makes about 50 eight-ounce drinks. Throw in another $0.20 for the cup, lid, and straw. That puts your cost per serving right around $0.50.

Now, if you're selling that frozen margarita for $12, you’re pocketing a cool $11.50 in gross profit on every single one. That’s the kind of margin that shows you just how much money these machines can churn out.

For a high-volume spot in Vegas, a frozen drink machine isn't just another appliance—it's a cash cow. With profit margins often hitting over 80%, the machine can pay for itself in just a few weeks, especially when the tourists are in town.

Analyzing Your Energy Consumption

Your power bill is a huge piece of the ownership cost puzzle, especially here in the Las Vegas heat. When your kitchen is hot, that compressor has to work overtime to keep everything frozen, and that means a higher electricity bill.

Here’s how to keep those energy costs from eating into your profits:

- Look for the Energy Star: Always check for models with the Energy Star certification. They're built from the ground up to be more efficient.

- Give It Room to Breathe: We talked about this before, but it’s worth repeating. Giving an air-cooled unit enough space for ventilation is the single best thing you can do to keep the compressor from working too hard.

- Use the Night Mode: A lot of the newer machines have a "standby" or "night" mode. It keeps the mix chilled overnight without freezing it solid, which cuts way down on power usage when you're closed.

Keeping your electricity usage in check is a massive part of running a profitable kitchen. If you're looking for more ways to save, check out our article on energy-efficient commercial refrigeration.

When you really dig into your cost per serving, your sale price, and your running costs like energy, you can build a solid financial forecast. It's a smart, data-first approach that turns your investment from a guess into a guaranteed profit-maker for your business.

We're Here to Help You Succeed in Vegas

Making it in the high-stakes, fast-paced Las Vegas restaurant world takes more than just a killer menu. You need workhorse equipment that keeps up with the relentless demand, day in and day out. We've walked through everything you need to know to turn a frozen beverage dispenser into a serious money-maker—from picking the right machine for our desert heat to keeping it running like new. Now, let’s talk about getting you the right gear.

The supplier you choose is just as important as the machine itself. You need someone who gets the unique grind of operating in Las Vegas, where equipment is pushed to its limits by extreme temperatures and constant use. That means a partner who stocks a solid selection of NSF-compliant machines that are built to last.

Your Local Equipment Experts

There's a huge advantage to sourcing your equipment right here in town. Forget waiting on a truck to haul your new machine across the country. We offer fast, free delivery to the Las Vegas area, often getting it to your door in just one or two business days. That kind of speed is a game-changer when you're launching a new spot or scrambling to replace a broken unit mid-rush.

When you work with a local partner, you're not just buying a piece of equipment; you're gaining an ally who knows this market inside and out. We can give you real, practical advice on the best setups—from commercial refrigerators and commercial freezers to high-capacity ice machines—that we know from experience can handle the Vegas heat.

In a city this competitive, your success hinges on having reliable tools that make customers happy and pad your bottom line. Investing in the right machine from a local partner you can trust isn't just another purchase. It’s a strategic move to set your business up for long-term success.

Ready to find the perfect frozen beverage dispenser for your spot? Browse our selection of commercial-grade machines or give our team a call for some personalized advice. We're here to help.

Got Questions? We’ve Got Answers.

When you're running a busy spot in Las Vegas, you don't have time for guesswork. Here are some of the most common questions we hear from operators about adding a frozen beverage dispenser to their lineup, along with some straight-up answers.

How Often Should I Be Cleaning This Thing?

Look, in a high-traffic city like Vegas, daily cleaning isn't just a suggestion—it's a must. Every single shift, your team needs to be wiping down the nozzles, cleaning the exterior, and emptying those drip trays. No exceptions.

As for a full breakdown, you’ll want to follow the manufacturer's guide. Typically, that means deep cleaning the hoppers, augers, and seals every 7-14 days. But if you're slinging anything with dairy, you'll need to do that deep clean way more often to keep the Southern Nevada Health District happy.

Can I Just Use Any Drink Mix I Find?

Absolutely not. This is a big one. You have to use a mix with the right sugar content, what we call the Brix level. If you try to run a low-sugar or sugar-free mix, it’s going to freeze into a solid block of ice. That’ll destroy your auger and gearbox faster than you can say "brain freeze."

Stick to the good stuff—high-quality commercial syrups made specifically for these machines. It protects your investment, keeps your machine running smoothly, and pours a perfect, delicious drink every time. This same logic applies to all your essential restaurant equipment, from your commercial refrigerators and commercial freezers to your ice machines—use them the way they were designed to be used.

What's the Biggest Rookie Mistake You See?

Hands down, the most common—and most expensive—mistake we see is bad ventilation. Air-cooled units need to breathe. They require several inches of open space around their vents to pull in cool air and push out hot air from the compressor.

Shoving a machine into a tight, stuffy corner in a blazing-hot Las Vegas kitchen is a recipe for disaster. The compressor will work itself to death, overheat, and fail on you. Giving your machine proper airflow is the single best thing you can do to make it last.

Ready to start pouring high-margin frozen drinks that'll keep customers coming back? Las Vegas Restaurant Equipment has the tough, NSF-certified machines built to handle our desert heat. Take a look at our full selection online at https://lasvegasrestaurantequipment.com and get free, fast shipping right to your door.