Designing a kitchen in the high-stakes, high-temperature world of Las Vegas isn't just about placing equipment—it's about building an engine. In a vibrant city like Las Vegas, with a diverse array of restaurants catering to every palate, a truly well-designed kitchen is the absolute backbone of any successful eatery. It has a direct hand in everything from ticket times and staff stress to food quality and, of course, your monthly power bill.

Let these principles be your guide to building a kitchen that not only survives but thrives under pressure.

Building a Kitchen That Thrives in Las Vegas

The desert presents a unique set of challenges. Whether you're running a massive buffet on the Strip or an intimate spot in Summerlin, the one constant is the need for a kitchen that can handle insane volume and extreme ambient heat. This is about more than just a floor plan; it's about crafting a space that empowers your culinary team to execute flawlessly, shift after shift.

At the very heart of this process is selecting essential restaurant equipment that’s actually built for this climate. Your kitchen's success hinges on having real workhorses that won't tap out when the summer heat is blasting.

Core Equipment for Vegas Operations

Your foundation starts with refrigeration and ice. For any Las Vegas operation, these aren't just boxes that get cold—they are the lifeblood of your inventory and your service. Skimping here is a recipe for disaster, leading to catastrophic food loss and service meltdowns, especially when you can least afford it.

Think of these non-negotiable pieces of essential restaurant equipment:

- Commercial Refrigerators: Your units absolutely must be rated for high ambient temperatures. A standard refrigerator will struggle, or even completely fail, when a Vegas kitchen hits 110°F. That puts thousands of dollars in inventory at risk. You need to look for models with beefy compressors and superior insulation.

- Commercial Freezers: Just like the coolers, your freezers have to hold their ground and maintain safe temps when the environment around them is fighting back. For any high-volume spot, a walk-in is essential. It gives you the bulk storage you need to keep a diverse menu humming.

- Ice Machines: In a city that truly never sleeps, a reliable ice supply is critical for your bar, beverage stations, and any kind of food display. You need to sit down, calculate your daily ice needs, and then pick a machine that can blow past that number without breaking a sweat.

Here's a mistake I see all the time: treating all commercial equipment as if it's created equal. An operator in Seattle has completely different environmental demands than someone in Henderson. Out here, your equipment's ability to fight off external heat is just as important as its internal cooling power.

Ultimately, designing a restaurant kitchen in Vegas means planning for resilience. Every single choice, from the workflow of the layout to the specific model of freezer you choose, has to be made with our demanding local environment top of mind. That’s how you build a kitchen that’s a true asset, not just a functional space.

Mapping Your Kitchen Workflow for Peak Efficiency

Forget about the shiny new equipment for a second. The most critical part of designing a high-performance kitchen is nailing the workflow. It's all about purposeful movement—choreographing the path food takes from the delivery truck to the guest's plate.

A well-planned kitchen flow eliminates wasted steps, prevents your team from literally running into each other, and keeps things moving smoothly even during the most chaotic Saturday night rush. This is especially true in a high-volume market like Las Vegas, where every second counts.

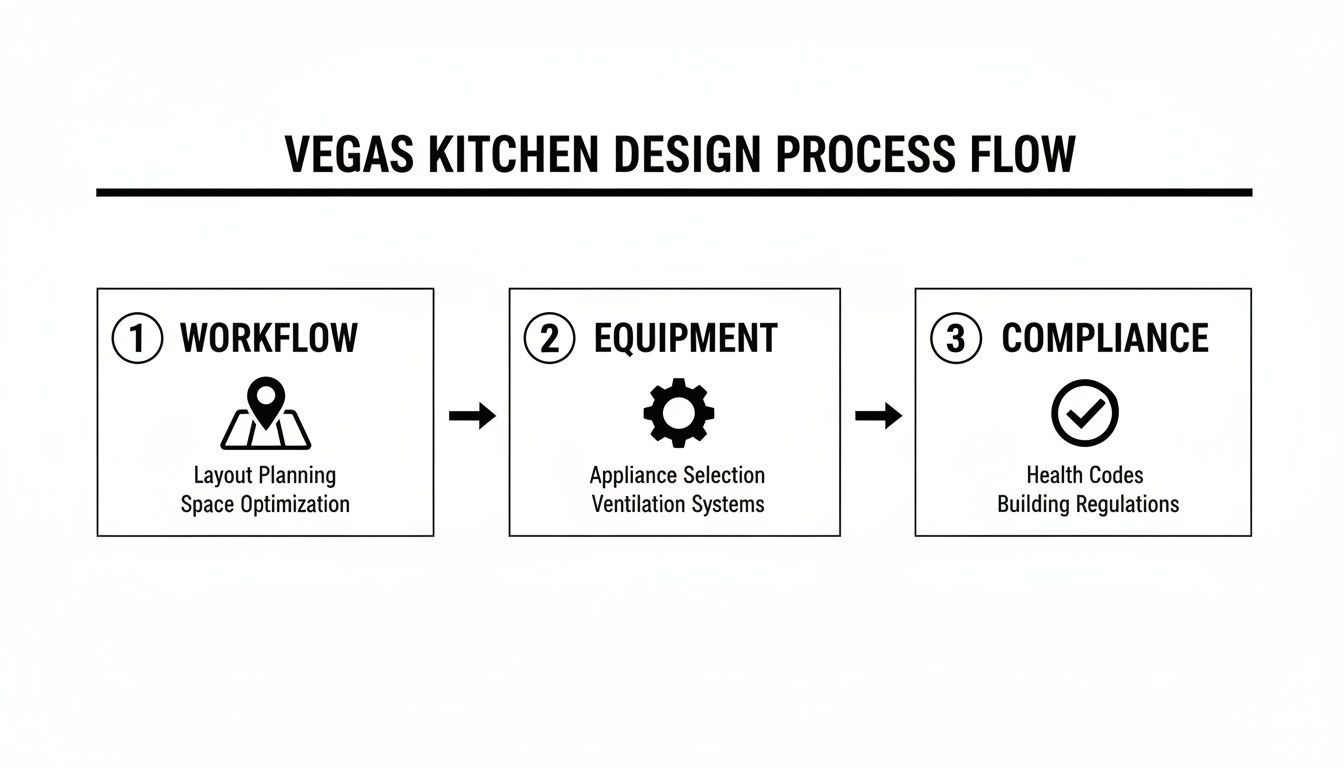

This chart breaks down the core phases of designing a kitchen that can handle the Vegas grind, starting with that all-important workflow.

Think of it this way: getting the flow right is the foundation. Everything else—from equipment choices to health code compliance—is built on top of it.

The Journey of an Ingredient

Let's walk through the life of a steak at a fictional Las Vegas spot, "Mojave Grill," a busy steakhouse just off the Strip.

First up, Receiving & Storage. The journey starts at the back door. Prime steaks and fresh produce arrive and are immediately checked in. The key is to have your storage right next to receiving to maintain the cold chain and save time. Those steaks go straight into a dedicated walk-in commercial refrigerator, bulk fries hit the walk-in commercial freezer, and a nearby ice machine keeps the bar supplied without anyone having to trek across the kitchen.

Next, Preparation. From the walk-in, a cook grabs the steak and heads to a prep station. This area needs sinks, cutting boards, and under-counter refrigeration. Crucially, raw meat prep has to be physically separate from where you’re prepping salads to avoid cross-contamination. No exceptions.

Then it's on to the Cooking Line—the heart of the action. The prepped steak hits the charbroiler. A smart line groups similar equipment together, like fryers, griddles, and ranges, all under one powerful ventilation hood.

Finally, Plating & The Pass. Once cooked, the steak is plated at a station right next to the line and slid onto the pass—that heated window where servers grab the finished dishes. This area needs to be an obstacle-free zone, acting as the final quality check before the food heads out to the dining room.

This logical flow means no one is backtracking. Cooks aren't dodging the dish pit to get to the cooler, and servers aren’t cutting through the hot line. It's organized chaos.

Choosing a Kitchen Layout for Your Vegas Concept

The layout you choose is what makes this flow possible. And in Vegas, with its wild diversity of restaurant concepts, there’s no single "best" layout. It all comes down to your menu and service style.

This table breaks down the most common layouts and where they fit in the Vegas scene.

Choosing a Kitchen Layout for Your Vegas Concept

| Layout Style | Best For (Vegas Concept) | Pros | Cons |

|---|---|---|---|

| Assembly Line | Quick-service (tacos, salads), ghost kitchens | Maximizes speed and output; easy to train staff. | Inflexible; not suited for complex or evolving menus. |

| Zone Style | Fine dining, steakhouses, complex menus | Allows for specialized stations (grill, sauté, pastry); prevents bottlenecks. | Requires more space and skilled staff for each zone. |

| Island Style | Large, open kitchens, chef-driven concepts | Promotes communication; allows the head chef to oversee all stations. | Can be inefficient if not designed perfectly; requires a lot of square footage. |

A common mistake I see is operators choosing a layout that looks impressive on paper but completely ignores how their team actually needs to work. A zone-style layout in a fast-food joint would be a disaster, just as an assembly line would kill the workflow in a fine-dining kitchen.

Your layout must serve your menu, not the other way around.

The Rise of the Open Kitchen

Here in Vegas, dining is theater, which is why the open kitchen concept is huge. It puts the culinary team on display, adding to the guest experience. It also builds trust—72% of diners say they view restaurants with open kitchens as cleaner and more reliable.

But an open kitchen is a double-edged sword. It demands an even more meticulous design. Ventilation has to be perfect to keep smoke out of the dining room. You have to think about noise control and the visual appeal of your equipment.

Everything on display, right down to your warewashing station, has to be spotless. This puts more pressure on your team and your processes to be flawless, all the time. To learn more about keeping that part of your operation humming, check out our guide on restaurant dishwashing equipment.

Selecting Equipment That Can Handle the Heat

Picking out your kitchen equipment is easily one of the biggest checks you'll write when you're setting up a new restaurant. But here in Las Vegas, where the summer heat can crank ambient kitchen temperatures past a blistering 100°F, your choices are more than just an investment—they're a matter of survival.

Forget standard commercial-grade. You need gear that's built from the ground up to perform under the kind of extreme stress that would make lesser equipment tap out.

Think of your equipment like your most dependable line cooks. They have to show up every single day, pull a double in the worst conditions imaginable, and never, ever break down. Let's walk through how to choose the true workhorses for a Vegas kitchen, starting with the absolute cornerstone of your operation: refrigeration.

The Foundation: Cold Line Equipment

In the desert, your cold line isn't just for storage. It’s your last line of defense against catastrophic food spoilage and a complete shutdown of service. A refrigerator or freezer conking out during a July heatwave can easily cost you tens of thousands in lost product and sales. This isn't a corner you can afford to cut.

Your number one priority has to be units rated for high ambient temperatures. This isn't just a fancy sticker; it means the compressor and insulation are beefed up to hold safe temps even when the kitchen around it feels like an oven. Ignoring this is a classic rookie mistake that many new Vegas operators learn the hard way.

Your refrigeration is the heart of your back-of-house. If it fails, everything grinds to a halt. The single best thing you can do to protect your investment is to prioritize units with powerful, oversized compressors and thick, high-density insulation.

As you lay out the kitchen, think about how each type of refrigeration fits into your daily flow.

- Commercial Refrigerators: These are your daily drivers. From the massive walk-in holding bulk produce and proteins to the reach-in units on the cook line and the under-counter models at prep, every single one needs to be a fortress against the heat.

- Commercial Freezers: Just like their refrigerated cousins, your freezers have to hold their ground. A walk-in freezer is a must for buying in bulk, while a simple upright reach-in gives your line cooks the quick access they need during the dinner rush.

Going for these high-performance units doesn't just save your food; it saves your wallet. Energy-efficient commercial refrigeration models can make a serious dent in your utility bills, which, as you know, go through the roof during Vegas summers.

Calculating Your Ice Needs

It’s easy to overlook, but your ice machine is a mission-critical piece of equipment. In this town, ice isn't just a utility; it's a core part of the hospitality experience. From craft cocktails on the Strip to the beverage stations at a sprawling buffet, running out of ice mid-service is not an option. Period.

To size your machine right, you need to do a little math on your peak daily usage. Here’s what to consider:

- Restaurant Seating: A good starting point is 1.5 lbs of ice per person.

- Bar Program: For a busy bar, you'll need way more. Plan for at least 3 lbs of ice per customer to cover cocktails, sodas, and water service.

- Other Uses: Don't forget ice for salad bars, raw bars, seafood displays, or any other back-of-house needs.

Let's say you have a 100-seat restaurant with a hopping bar. Your math might look like this: (100 seats x 1.5 lbs) + (75 bar patrons x 3 lbs) = 150 lbs + 225 lbs = 375 lbs per day. My advice? Always buy a machine that can produce at least 20% more than your peak estimate. That buffer will save you on unexpectedly busy nights and accounts for the fact that machines just don't run as efficiently in extreme heat.

Beyond the Cold Line: The Hot Side and More

While your cold line is the foundation, the rest of your equipment is what makes the kitchen hum. Your cooking equipment, ventilation, and warewashing systems all need to be chosen with the same high-volume, desert-climate reality in mind.

And when it comes to prep surfaces, you need something that can take a beating. This comprehensive guide to choosing and installing kitchen countertops is a great resource for picking materials that are both durable and hygienic.

Here are the other key players to focus on:

- Cooking Equipment: Your ranges, fryers, griddles, and charbroilers should be a direct reflection of your menu. Go for heavy-duty models that can run all day and all night. I'm a big fan of modular units because they give you the flexibility to adapt as your menu changes.

- Ventilation Hoods: A beast of a ventilation system is non-negotiable. In Vegas, it’s not just about smoke and grease; it’s about pulling that oppressive heat out of the kitchen to create a workable environment for your team. Make sure your hood is oversized to effectively cover every piece of cooking equipment.

- Warewashing Systems: Water is gold in the desert. Look for a high-temperature, energy-efficient commercial dishwasher that sanitizes perfectly while using as little water as possible. And remember, the health department will still require a properly sized three-compartment sink for manual washing.

At the end of the day, every piece of steel you put in that kitchen contributes to its success or failure. By choosing durable, high-performance equipment designed for the unique challenges of Las Vegas, you’re building a foundation for efficiency, safety, and a profitable future.

Meeting Clark County Health Codes and ADA Standards

Let's talk about the less glamorous side of kitchen design: rules and regulations. When you're building out a restaurant in Las Vegas, your design isn't just about creating a great workflow—it has to be safe, accessible, and completely legal. Think of compliance not as a final hurdle, but as the very foundation of your entire build-out.

Getting this right from the beginning is non-negotiable. Trust me, navigating the codes from the Southern Nevada Health District (SNHD) and the Americans with Disabilities Act (ADA) from day one will save you a world of headaches. Failing an SNHD inspection can slam the brakes on your opening for weeks, and that's thousands of dollars in lost revenue you'll never get back. These codes aren't just red tape; they're there to prevent foodborne illness and protect your customers and staff.

Decoding Southern Nevada Health District Rules

The SNHD has a very specific, very detailed playbook for how a food establishment must be built. These aren't suggestions. They dictate everything from the materials on your walls to the exact placement of your sinks.

An inspector’s first sweep will always include the surfaces. Every floor, wall, and countertop in your prep and storage areas must be smooth, durable, and non-porous. This isn't just for looks; it's to prevent grease and bacteria from finding a home and to make sure your deep cleans are actually effective. That’s why you see materials like sealed concrete floors, stainless steel backsplashes, and FRP (fiberglass reinforced plastic) panels in nearly every professional kitchen.

Sanitation is where inspectors really focus. The rules around sinks are strict, but they make perfect sense:

- Three-Compartment Sink: This is your warewashing workhorse. It absolutely has to be big enough to fully submerge your largest stock pot, with separate drainboards for dirty and clean dishes. No exceptions.

- Handwashing Sinks: You need dedicated hand sinks—used only for handwashing—in every major prep zone and near your dish pit. Getting the placement right is crucial. For a deep dive, check out our guide on setting up a compliant hand washing station.

- Food Prep Sink: If you’re washing any kind of produce, you must have a separate, dedicated sink for it. This is a critical step in preventing cross-contamination.

A classic rookie mistake is trying to save space by cutting down on sinks. The SNHD code is crystal clear. Attempting to make one sink do the job of two is one of the quickest ways to fail an inspection.

Temperature control is another big one. Your commercial refrigerators must hold at 41°F or below, and your freezers need to stay at a solid 0°F or below. Don't cheap out here—invest in quality units with reliable digital thermometers. It’s a must for both food safety and passing inspection.

Creating an Inclusive and ADA-Compliant Workspace

Beyond the health codes, your kitchen needs to be a functional workspace for all employees, including those with disabilities. The Americans with Disabilities Act (ADA) doesn't just apply to your dining room; it extends right into the heart of your operation. Creating an accessible back-of-house fosters an inclusive culture and shields you from serious legal trouble.

Here are a few key ADA points to bake into your kitchen design:

- Clear Pathways: Major walkways need to be at least 36 inches wide to accommodate a wheelchair. This isn’t something you can fix later; it has to be part of the initial layout.

- Accessible Workstations: Plan for at least one workstation with a lower counter, typically between 28 to 34 inches high, with clear knee space underneath.

- Reachable Storage: Make sure some shelving, especially for everyday items, is within easy reach for someone who is seated.

Building compliance into your plans from the very start will save you an incredible amount of time and money. And it doesn't stop on opening day; keeping your kitchen compliant means maintaining your equipment properly. For instance, your ventilation system is critical for both safety and code. Learning about Mastering Commercial HVAC Maintenance Contracts can help you ensure your systems are always up to snuff. At the end of the day, a compliant kitchen is a successful kitchen.

Integrating Smart Tech and Sustainable Design

The modern kitchen is intelligent. It's efficient. And it's keenly aware of its resources. When you're designing a restaurant kitchen in a market as demanding as Las Vegas, weaving in smart technology and sustainable practices isn't just a trendy move—it's a critical competitive edge.

This isn't about adding flashy gadgets for show. It’s about building a resilient, intelligent kitchen that can handle the punishing heat of the Las Vegas climate and the non-stop pace of a high-volume operation. Let’s be blunt: a smarter kitchen is a more profitable kitchen.

Harnessing the Power of Smart Kitchen Technology

The days of just hoping a critical piece of equipment doesn't fail mid-service are over. The Internet of Things (IoT) has officially entered the kitchen, creating a connected ecosystem where your appliances talk to you, optimizing their own performance and flagging potential disasters before they happen.

This shift is changing how kitchens operate on a global scale. In fact, 52% of global operators are looking to invest in smart tech and automation in 2025 to make their teams more efficient. For more on these global restaurant trends, check out the insights on Restroworks.com.

We're seeing IoT-connected ovens, fridges, and dishwashers that feed you real-time data to slash energy use and predict maintenance needs. Imagine your commercial refrigerator shooting an alert to your phone because its internal temperature is creeping into the danger zone. That one text could save you thousands in spoiled inventory—a very real nightmare during a Vegas heatwave.

Here’s where smart tech really makes a difference on the floor:

- IoT-Connected Refrigeration: Your walk-ins and reach-ins can monitor their own temperature, compressor cycles, and energy draw. This data is gold for predictive maintenance, helping you avoid those costly emergency repair calls.

- Automated Cooking Systems: Smart combi ovens and cooktops deliver perfect consistency, which is everything for guest satisfaction. You can program them with your recipes to make sure every dish is executed flawlessly, drastically cutting down on waste from human error.

- Smart Energy Management: Get a real-time view of your utility usage. These systems pinpoint which appliances are energy hogs and help you tweak operations to save money during peak hours.

By integrating smart technology from the very start of the design phase, you're not just buying equipment; you're investing in an insurance policy against downtime and a tool for long-term operational excellence.

Sustainable Design for the Desert Climate

In a city defined by scorching heat and precious water, sustainable design isn't just an ethical choice—it’s a financial necessity. Your kitchen design can either fight the Las Vegas environment or work with it. Trust me, the latter is far more profitable.

The biggest win here is slashing your utility bills, which can get absolutely brutal during the summer months. It all starts with the equipment you choose.

Prioritizing Energy and Water Efficiency

Your equipment spec sheet is the single biggest factor in your kitchen's environmental footprint and, by extension, your utility costs.

Focus your investment here for the biggest impact:

- ENERGY STAR® Rated Equipment: Don't just glance at the sticker—actively seek out commercial refrigerators, freezers, ovens, and dishwashers with the ENERGY STAR® label. These units are certified to be significantly more efficient, which you'll see on your power bill every single month.

- Water-Saving Fixtures: Low-flow pre-rinse spray valves are non-negotiable for your dish pit. A high-efficiency valve can save hundreds of gallons of water a day. In the Mojave Desert, that's not just a small savings; it's a critical one.

- High-Efficiency Ice Machines: Modern ice machines can be incredibly smart. Look for air-cooled models with intelligent harvesting cycles that only produce ice when needed, cutting back on both water and electricity.

Beyond the big-ticket items, think about your waste management from day one. Designing dedicated space for recycling and composting bins makes it easy for staff to do the right thing, which reduces your landfill waste and the costs that come with it. A smart, sustainable kitchen is a lean, cost-effective operation that’s better for the planet and your profit margins.

Answering Your Las Vegas Kitchen Design Questions

Bringing a new restaurant to life in Las Vegas is a whole different ballgame. As you start turning that big idea into a real, working kitchen, a ton of questions are going to pop up. Let's tackle some of the most common ones I hear from restaurateurs trying to make their mark here.

This city has everything from massive Strip buffets to tiny neighborhood spots, so there's no single magic formula. But getting a handle on the money, the workflow, and the local rules is the only way to build a kitchen that can take the heat.

How Much Does a Restaurant Kitchen Cost in Las Vegas?

This is always the first question, and the honest answer is: it's a huge range. For a professional kitchen in Las Vegas, you should plan for anywhere from $200 to over $500 per square foot.

A small coffee shop or ghost kitchen setup might get started around $50,000. But if you're looking at a high-end steakhouse on the Strip, that number can easily blow past $750,000. The big-ticket items are always the heavy-duty plumbing and electrical, a powerful ventilation system (which is non-negotiable in the desert), and the equipment package itself.

I tell every client the same thing: set aside a contingency fund of 15-20% of your total budget. Always. Unexpected construction hang-ups or equipment getting stuck in transit happens more often than not. That buffer is what saves you from a total shutdown.

What Is the Biggest Design Mistake in a Vegas Kitchen?

I've seen it time and time again. The single most expensive mistake you can make is under-powering your refrigeration. More specifically, it’s buying standard units that aren't built for high ambient temperatures. Vegas is a brutal environment for any kind of cooling equipment.

Your average commercial refrigerator will choke and die when your kitchen hits peak summer temperatures. That means spoiled inventory, a service that grinds to a halt, and an emergency call to a repair tech who's going to charge you a fortune.

You have to invest in heavy-duty commercial refrigerators, commercial freezers, and ice machines with oversized compressors. It's not a luxury—it's the only way to protect your product and keep your doors open when it's 115 degrees outside.

Do I Need a Professional Kitchen Designer?

Look, you could sketch out a simple kitchen on a napkin, but it's a terrible idea. Bringing in a professional commercial kitchen designer who knows the Southern Nevada Health District (SNHD) code book inside and out is one of the smartest checks you'll write.

Here’s what their experience gets you:

- Smarter Workflow: They'll design a layout that actually flows with your menu, preventing those frustrating bottlenecks that kill ticket times and burn out your staff.

- Code Compliance: They know the local regulations and will get your design approved from the start. This saves you from the nightmare of a failed inspection and having to tear out brand-new work.

- The Right Gear: They have relationships with suppliers and know which equipment brands can actually survive in a desert kitchen, helping you get the best value for your budget.

In a market that moves as fast as Vegas, getting the kitchen right the first time is everything. It's the engine of your entire operation, and it needs to be built to last.

Ready to equip your Las Vegas kitchen with reliable, high-performance equipment built to handle the desert climate? At Las Vegas Restaurant Equipment, we offer a curated selection of new, warranty-backed commercial refrigerators, freezers, ice machines, and cooking equipment at lean, showroom-free prices. Get started today at https://lasvegasrestaurantequipment.com.