A top-tier food truck design isn't just a kitchen on wheels; it's a high-speed engine built for durability and profit. Forget the cool exterior wrap for a second. A truly successful design starts from the inside out, with a layout that flows perfectly with your menu, equipment that can take a beating, and a build that nails every local health code from day one.

Your Blueprint for a High-Performance Las Vegas Food Truck

In the Las Vegas food truck game, you win or lose before you ever serve a single customer. It all comes down to the design. This vibrant city is a different beast altogether—scorching desert heat, massive festival crowds, and wild nightlife rushes put insane demands on your truck. A cookie-cutter design just won't survive a late-night slam on the Strip.

Your truck has to be a purpose-built machine. Every square inch needs to be thoughtfully planned out to slash ticket times and keep your crew sane and efficient. This starts with a hard look at your menu and how you can translate those dishes into a smooth, physical workflow inside a metal box.

The Foundation of a Vegas-Ready Design

Before you start sketching out where the fryer goes, you need to lock in the core pillars that will make or break your entire operation. These aren't separate ideas; they all work together to create a system that just works.

Here's how we break down the essentials when we're building a truck for the desert:

Core Pillars of Food Truck Design

| Pillar | Primary Focus | Key Considerations for Las Vegas |

|---|---|---|

| Menu-Driven Workflow | Creating a logical, step-by-step path from raw ingredients to finished product. | High-volume means no wasted steps. The layout must minimize movement and prevent staff from bumping into each other during a rush. |

| Heat-Resistant Equipment | Selecting gear that performs reliably under extreme ambient temperatures. | 110°F days are common. Standard coolers will fail. You need oversized compressors and heavy-duty insulation to hold safe temps. |

| Code Compliance | Building to meet or exceed all Southern Nevada Health District (SNHD) regulations from the start. | The SNHD has specific, strict rules. Failing an inspection means costly rebuilds and lost revenue. Build it right the first time. |

Getting these three pillars right from the jump is non-negotiable. It’s the difference between a truck that prints money and one that’s constantly breaking down.

Essential Equipment for the Desert Climate

Think of your truck as a specialized culinary weapon. You're not just a restaurant; you're a mobile outpost battling the elements, and you need the right tools for the job.

High-performance commercial refrigerators and commercial freezers are at the top of that list. These are essential restaurant equipment pieces needed for success. We're talking about units that can keep their cool even when the asphalt outside is hot enough to cook on. This isn't a place to cut corners.

Just as critical is a solid ice machine. In this climate, cold drinks are a massive profit center. Relying on bagged ice is a rookie mistake that will cost you big time when you run out mid-service. An onboard ice machine gives you a steady supply, letting you meet that demand and pad your bottom line.

The industry has gotten a lot smarter about truck design, especially in high-traffic markets like Vegas. The focus is now squarely on NSF-listed refrigeration and high-output cooking gear that can handle the volume and the heat. Staying on top of these crucial food truck market trends is key to staying ahead of the competition.

A well-designed food truck is a promise. It’s a promise of fast, consistent service to your customers, and a promise of a safe, efficient workspace for your crew. Skimping on the design is like building a house on a shaky foundation—it’s a recipe for disaster in a market as tough as Las Vegas.

Designing Your Kitchen for Maximum Workflow

The kitchen is the heart and soul of your food truck—it’s where you make your money. A smart layout isn't just about cramming in all your equipment. It's about choreographing a dance where every move has a purpose and every second counts. This is non-negotiable in a market like Las Vegas, which is home to a diverse array of restaurants that cater to every palate, setting the bar for speed and quality incredibly high.

Let's get real about organizing this tight space. Your kitchen's workflow is the journey an order takes from the ticket printer to a happy customer. You're aiming for a logical, step-saving flow that keeps your crew from bumping into each other when the dinner rush hits.

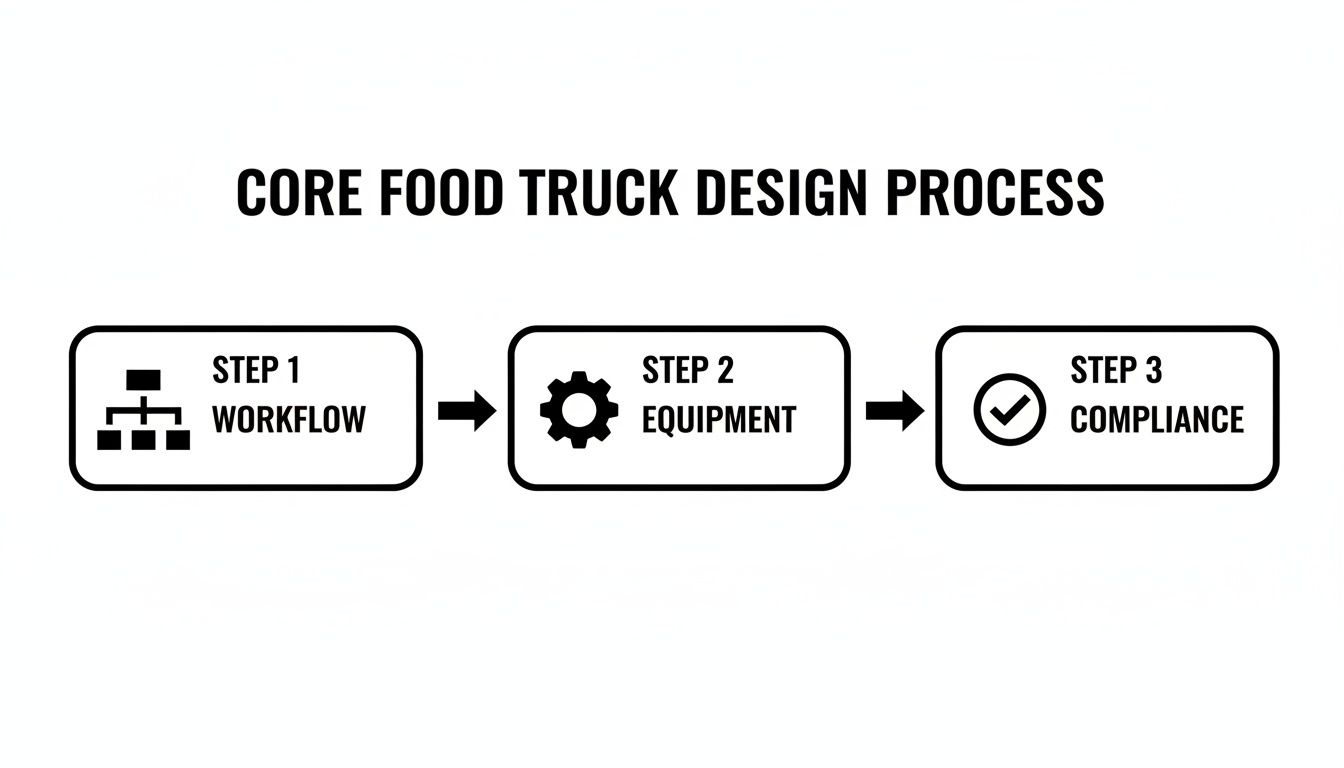

This breakdown shows the core stages of a solid food truck design. It all starts with workflow, which then informs your equipment choices, all while staying within the lines of health and safety rules.

The big takeaway here? Your workflow determines what equipment you need, and both of those things have to fit within the strict rules of your local health department.

Choosing Your Layout Model

Most food truck kitchens follow one of two models: the assembly line or the zone-based layout. The right one for you comes down to what you're cooking.

- Assembly Line Layout: This is your go-to for linear menus like tacos, burgers, or sandwiches. Stations are set up in order: cold storage, prep, cooking, and finally, finishing and plating. An order just moves straight down the line, with each person handling one specific step.

- Zone-Based Layout: If you have a more complex menu with a lot of different dishes, this is a better fit. You’ll divide the kitchen into functional "zones," like a fry station, a grill station, and a cold prep station. This lets your crew fire multiple dishes at once without getting in each other's way.

Just imagine the nightmare of sticking your commercial refrigerator at the back of the truck when your main prep counter is up front. During a rush, that one bad decision could easily add 10-15 seconds to every single order. That kills your ticket times and burns out your staff.

Mapping the Order Journey

To really nail your food truck design, you need to walk through the process of making your most popular items. I mean literally, walk the path from start to finish.

- Cold & Dry Storage: This is where it all begins. Your main commercial freezer and fridge have to be right next to your primary prep area. No exceptions. Every extra step is wasted time.

- Prep Station: This is where the magic starts—chopping, mixing, portioning. It needs to be directly beside your cold storage with plenty of dedicated counter space.

- Cooking Line: This is for your heavy-hitting equipment—fryers, griddles, and ranges. Arrange them based on what you use most and in what order they're needed to complete a dish.

- Finishing & Plating: This is the last stop before the window. It’s where you add sauces, assemble orders, and box everything up. Your ice machine should be right here, too, so you can fill drink orders without taking a single extra step.

When you're working with a small crew, tiny design mistakes—a poorly placed fryer, not enough room for sandwich prep, or awkward undercounter refrigeration—add up to long ticket times and a tired, frustrated team. In places like Las Vegas and Henderson, trucks might run 10–12 hour shifts in 100°F+ summer heat. A good layout, reliable refrigeration, and killer ventilation aren't luxuries; they're essential for productivity and safety.

The best food truck kitchen just feels right. Every tool, ingredient, and piece of equipment is exactly where your hand reaches for it. That kind of intuitive design doesn’t happen by accident. It comes from thinking through every single step your team will take, hundreds of times a day.

For any high-volume truck, integrating smart kitchen storage ideas for small spaces is an absolute game-changer. Think vertical shelving, undercounter drawers, and magnetic knife strips. These tricks turn dead space into valuable real estate, keeping your prep areas clear and your workflow lightning-fast. At the end of the day, a well-designed kitchen is one where the layout itself does half the work for you.

Selecting Equipment That Survives the Vegas Grind

In Las Vegas, your kitchen equipment isn't just a tool—it's your lifeline. Between the brutal desert heat and the crushing volume of customers at events on the Strip or local festivals, this is one of the toughest environments for a food truck to operate in. Let’s be blunt: standard equipment will fail you, probably at the worst possible time.

This is about choosing commercial-grade, NSF-certified gear that’s built from the ground up to endure these extremes. Think of every piece of equipment as an investment in your uptime. Every breakdown during a dinner rush costs you money and chips away at your reputation. You have to build tough from the start.

The Unforgiving Reality of the Desert Climate

The single biggest enemy of your mobile kitchen in Southern Nevada is the heat. We’re not just talking about the 100°F+ air temperature. We’re talking about the sun baking the metal shell of your truck, easily pushing the inside temperature into the danger zone. This puts an almost unbelievable strain on your refrigeration compressors and electrical systems.

You absolutely have to select equipment specifically rated for high-ambient-temperature environments. This isn't a "nice-to-have" feature; it's a non-negotiable requirement for food safety and operational survival here.

Core Cooling Equipment Your Truck Can't Live Without

Refrigeration is the heart of your operation. If your coolers can't hold their temp, the health department will shut you down. It’s that simple.

- Commercial Refrigerators: These are the workhorses. You need stainless steel models with oversized, high-efficiency compressors that can keep things cold even when your line cooks are opening the doors every 30 seconds.

- Commercial Freezers: The same logic applies here. A freezer that struggles in the heat means melted, ruined product and thousands of dollars in waste.

- Ice Machines: An onboard ice machine is a must-have in Vegas. Cold drinks are a massive profit center, and you can’t rely on running out for bagged ice during a festival. A dedicated, air-cooled undercounter unit is your ticket to a reliable supply.

Your refrigeration system is the most critical investment you will make in your truck. Spend the money on heavy-duty, high-performance units from the get-go. It will save you from the nightmare of spoiled inventory and lost sales down the road.

Optimizing Your Cooking and Prep Line

Once you’ve got your cooling dialed in, it’s time to build out the hot line and prep areas. The gear you choose here directly dictates your speed and ticket times.

You'll need a griddle with high BTUs that recovers its heat almost instantly after you slap down a dozen cold burger patties. Your fryers need to do the same, holding temperature through back-to-back basket drops. This kind of performance is what separates the pros from the trucks that can't handle the rush.

A real game-changer for workflow is a dedicated sandwich prep table. These units are brilliant—they combine refrigerated ingredient wells up top with an undercounter fridge below, creating a self-contained station. This design cuts down on wasted steps and keeps everything a cook needs right at their fingertips.

For a complete breakdown of everything you might need, check out this comprehensive food truck equipment list. It’s a great starting point to make sure you don't miss anything.

Undercounter vs. Reach-In Units

A big question that always comes up in a food truck design is whether to go with undercounter refrigeration or full-size reach-in units. The truth is, you’ll probably need both.

When you're outfitting a truck for the demands of Las Vegas, "standard" just won't cut it. Your equipment needs to be a step above to handle the heat and the crowds.

Here’s a quick look at what that means for your most critical pieces.

Essential Food Truck Equipment for Las Vegas

| Equipment Type | Standard Feature | Las Vegas Must-Have Feature | Why It Matters |

|---|---|---|---|

| Refrigerator | Holds temp at 40°F | High-ambient rating (up to 100°F+), oversized compressor | Prevents the unit from failing on hot days, ensuring food safety and avoiding costly shutdowns. |

| Griddle | Even heat distribution | High BTU output, rapid heat recovery plates | Keeps up with high-volume orders without slowing down, maintaining consistent quality. |

| Fryer | Basic thermostat | High-efficiency burners, fast temperature recovery | Allows for continuous frying during a rush without getting bogged down or producing greasy food. |

| Ice Machine | Standard production | Air-cooled system, designed for high-temp operation | Ensures a constant supply of ice for profitable drink sales, even when the truck is hot. |

Choosing the right gear isn't just about features; it's about survival. Investing in these "Vegas-proof" specs from the beginning is the smartest decision you can make.

Ultimately, the best layouts use a hybrid approach. Put undercounter units in your main prep line for quick access to your most-used items. Then, place a larger reach-in at the end of the line or in a less-critical space for bulk storage. This gives you the perfect balance of efficiency and capacity, setting you up for a smooth, high-volume service.

Power Plumbing and Ventilation That Keep You Running

A perfect layout is great, but it means nothing if the lights go out or the plumbing backs up in the middle of a dinner rush. Let's be real: the unseen systems—power, plumbing, and ventilation—are the true engine of your food truck. Here in Las Vegas, with our crazy climate and non-stop pace, these systems are what separate the pros from the trucks that can't last a full shift.

Getting them right is a non-negotiable part of a functional food truck design. This is where your investment in quality restaurant equipment really shows its worth. Your commercial refrigerators and fryers are only as good as the power source keeping them alive. Let's break down how to engineer these systems to keep you serving, no matter how wild the Vegas crowds get.

Sizing Your Power Plant Correctly

Underestimating your power needs is one of the most common—and most disastrous—mistakes new owners make. A generator that's too small will constantly trip your breakers, especially when everything kicks on at the start of the day. Your commercial freezer and air conditioner draw a massive amount of amps on startup.

To sidestep this nightmare, you have to calculate your total electrical load. It's not as scary as it sounds. Every piece of equipment has a spec sheet listing its wattage and amperage.

- Make a List: Open up a spreadsheet and list every single electrical item. I'm talking everything from the big commercial refrigerators and your ice machine down to the lights and your POS system.

- Find the Wattage: For each item, find its "running" wattage and, more importantly, its higher "startup" or "peak" wattage. That startup surge is the breaker-killer.

- Do the Math: Add up the running wattage of all the equipment you'll have on at the same time. Your generator's continuous output absolutely must be higher than this number.

- Build in a Buffer: The golden rule is to get a generator with a peak output at least 25-30% higher than your total startup load. This buffer handles unexpected power spikes and keeps your generator from redlining all day, which will seriously extend its life.

Don't ever guess your power needs. A tripped breaker during a festival rush means cold fryers, melting ice, and a line of angry customers walking away. Do the math and invest in a generator that can handle your whole operation without breaking a sweat.

Navigating Southern Nevada Plumbing Codes

Food truck plumbing is a self-contained, closed-loop system, and believe me, the Southern Nevada Health District (SNHD) has very specific rules you have to play by. These regulations are all about food safety, and they are not optional. Building it right the first time will save you the headache and expense of failed inspections and costly rebuilds.

The core of your system is a freshwater tank and a larger wastewater (or greywater) tank. A huge SNHD rule is that your wastewater tank must be at least 15% larger than your freshwater tank. This is to prevent disgusting and illegal overflows.

On top of that, every food truck in Clark County is required to have:

- A Three-Compartment Sink: You need this for the classic wash, rinse, and sanitize process for all your dishes. Each basin has to be big enough to completely submerge your largest pot.

- A Separate Handwashing Sink: This sink is only for washing hands. It must have hot and cold running water, soap, and paper towels right there.

Another critical piece of the plumbing puzzle is the grease trap. Sizing it correctly prevents nasty clogs and keeps you compliant with environmental codes. For a deeper dive, learning how to master grease trap sizing is a must for any serious mobile kitchen operator.

Mastering Ventilation in the Desert Heat

In the brutal Las Vegas heat, ventilation is much more than a comfort issue—it's a critical safety system. A properly designed system pulls grease-filled vapor, stifling heat, and dangerous gases like carbon monoxide out of your small kitchen space.

Your commercial hood and exhaust fan are the heart and soul of this system. The hood itself needs to extend at least six inches past your cooking equipment on all sides to make sure it's actually catching all the smoke and steam.

The real hero, though, is the exhaust fan. It has to be powerful enough to create negative air pressure, pulling fresh air in while shooting the hot, greasy air out. Not only does this keep your crew cooler and safer, but it also stops a sticky film of grease from coating every single surface, which is a massive fire hazard. A powerful, correctly sized ventilation system isn't a luxury; it's an essential part of any successful food truck design built for the desert.

Building a Compliant Truck from the Ground Up

Trying to figure out Las Vegas health codes can feel like you're lost in a maze. One wrong turn in your food truck design, and you're staring down the barrel of failed inspections, maddening delays, and a budget-busting rebuild. Getting your truck built to code isn’t just about checking off boxes; it’s about making smart decisions right from the get-go to ensure your kitchen is legal, safe, and ready to roll anywhere in Clark County.

It all starts with the bones of your truck—the materials you choose. The Southern Nevada Health District (SNHD) inspectors are meticulous about every single surface. They’re looking for materials that are tough, non-porous, and ridiculously easy to keep sanitized.

That means your walls and ceilings need to be a smooth, non-absorbent surface like stainless steel or FRP (fiberglass reinforced plastic). When it comes to countertops and prep areas, it has to be food-grade stainless steel, no ifs, ands, or buts. For the floor, you'll need a commercial-grade, non-slip flooring that can take a beating from heavy foot traffic and constant cleaning.

Mastering SNHD Requirements

Once you've got your materials sorted, you need to focus on the core systems SNHD mandates. These aren't just suggestions; they're the absolute requirements to get your permit.

- Fire Suppression System: A professionally installed and certified fire suppression system is completely non-negotiable, especially with the kind of high-heat cooking gear common on the Vegas scene. This system needs to cover every cooking appliance and tie into an automatic shut-off for your gas line.

- Sink Configuration: As we've mentioned, the three-compartment sink for washing, rinsing, and sanitizing is a must. But just as critical is a totally separate sink just for handwashing. Its placement is everything—it has to be right there and easily accessible from your prep and cooking stations. To really nail this, you should review the fine details of a proper hand washing station to make sure you meet every single requirement.

- Proper Ventilation: Your commercial hood has to be the right size and installed perfectly over your entire cook line. In the desert heat, effectively pulling out grease and hot air is a massive safety issue.

You should really think of your SNHD inspector as a partner you want to impress. Your goal is to build a truck that makes their job simple. When they walk in and see clean welds, perfectly sealed floors, and equipment that’s installed by the book, it just builds confidence and makes the whole permitting process go that much smoother.

Designing for Durability and Modern Demands

Meeting code is just the starting line. A truly well-designed food truck is built with the future in mind. The industry has really shifted away from basic van conversions and more toward purpose-built mobile kitchens designed from the ground up.

This evolution is driven by the need for more robust electrical systems that can handle high-efficiency equipment, more flexible workflows, and branding that pops on the street and on Instagram. Understanding the legal side of things is crucial; navigating building codes and regulations gives you a solid foundation for the structural and safety standards that will dictate your build.

By sweating these details from day one, you’re not just building a truck that will pass inspection. You're engineering a business built for long-term success in the cutthroat Las Vegas food scene.

Answering Your Biggest Food Truck Design Questions

When you're mapping out a food truck design for a market like Las Vegas, questions are a great sign. It means you’re already sweating the details that separate the trucks that thrive from those that just survive. We’ve pulled together some of the most common questions we get from first-time owners to give you some straight-up, real-world answers.

What’s the Real Cost to Build a Food Truck for Vegas?

This is the million-dollar question, isn't it? The honest-to-goodness answer is that the price tag can swing wildly. You might be able to get on the road with a basic, used truck and some older equipment for around $50,000. But if you're looking at a brand-new, fully custom build with all the best gear, you can easily blow past $150,000.

What drives that cost? It boils down to the truck itself, the quality of your cooking equipment, and the one thing you absolutely cannot skimp on here: refrigeration.

In Las Vegas, your commercial refrigerator and commercial freezer are your lifeline. This is not the place to cut corners. Investing in heavy-duty, high-ambient units that can actually hold their temperature in the brutal desert heat is non-negotiable. Go cheap here, and you're signing up for thousands in spoiled food, failed health inspections, and agonizing downtime that will cost you far more than you "saved."

What's the Number One Design Mistake New Owners Make?

Without a doubt, the single biggest and most painful mistake is underestimating your power needs. It’s a classic rookie move. Someone buys a generator that looks great on paper, but it can't handle the massive power surge when the commercial refrigerator, freezer, AC, and flat-top all decide to kick on at the same time.

Suddenly, you're tripping breakers in the middle of a slammed dinner rush. Your kitchen goes dark, sales stop dead, and you've got a line of hungry, unhappy customers. Do the math. Add up the total wattage of everything you own—especially the peak startup draw—and then buy a generator with at least 25% more capacity than that number. Consider that extra juice your insurance policy against a total meltdown.

Think of your generator as the heart of your truck. If it's too weak to pump enough power to all your vital equipment, the entire system will fail. A strong, reliable power source is the foundation of a smooth, uninterrupted service.

Do I Really Need an Ice Machine on a Vegas Food Truck?

Yes. Full stop. In a city where the temperature regularly blasts past 100°F, an onboard ice machine isn't a luxury—it's a profit machine. Trying to rely on constant runs for bags of ice is a logistical nightmare. It's expensive, it melts faster than you can use it, and you will run out when you're busiest.

A good undercounter commercial ice maker gives you a steady, reliable supply for high-margin drinks like sodas and specialty lemonades, which are absolute gold in the Vegas market. Just make sure you get an air-cooled model built to perform in high heat. It makes your life easier, cuts daily costs, and protects a crucial revenue stream.

How Big a Deal Is the Exterior Wrap in My Design?

In a city as loud and visually overwhelming as Las Vegas, your truck’s wrap is your single most important marketing tool. It’s a giant, rolling billboard that has to cut through the noise and grab eyeballs instantly. A bland, generic wrap just disappears.

Your design needs to be bold and clean, something people can read and understand from a distance. It has to look just as good glowing under neon and festival lights at night as it does in the bright desert sun. Your wrap should scream who you are.

A winning wrap has to have:

- A Clear, Bold Logo: This should be the star of the show.

- Readable Menu Highlights: Don't list your whole menu. Just your heavy hitters.

- Social Media Handles: Make it dead simple for people to find you online.

- High-Contrast Colors: Pick a palette that won't blend into the city or desert background.

A professional, head-turning wrap doesn't just get you your first customer; it builds a brand that people start looking for. It's an investment that pays for itself every time someone walks up to your window because your truck caught their eye.

Ready to equip your truck with gear that can handle the Las Vegas grind? At Las Vegas Restaurant Equipment, we specialize in new, warranty-backed commercial refrigerators, freezers, ice machines, and cooking equipment designed for high-volume, high-heat environments. Get showroom-free pricing and fast, free shipping to start your build with confidence. https://lasvegasrestaurantequipment.com