Your food truck is your business, your kitchen, and your brand all rolled into one. The food truck cooking equipment you choose is the engine that drives it all, from the high-powered cooking gear churning out orders to the refrigeration keeping your ingredients fresh. This isn't just about filling a space; it's about building a compact, rugged kitchen with commercial-grade griddles, fryers, and ventilation tough enough for the road.

Building Your Mobile Kitchen for the Las Vegas Grind

Welcome to the big leagues of the food truck world. Here in the vibrant city of Las Vegas, where you'll find a diverse array of restaurants that cater to every palate, success is about more than just a killer menu—it’s about having a kitchen on wheels that’s tough enough to handle the grind. You're up against a unique challenge: picking equipment that fits a tiny footprint, meets some of the strictest health codes in the country, and doesn't quit in the face of brutal desert heat.

Think of your equipment as the most valuable members of your crew. Your commercial refrigerators are the lifeblood, protecting your inventory. Your griddles are your moneymakers, pushing out orders to hungry crowds on the Strip. Every single piece you install is critical to your success.

Why Las Vegas Changes the Game

Running a food truck in Vegas is a completely different beast. The combination of scorching heat and non-stop demand puts your gear to the ultimate test.

- Relentless Heat: That standard-issue fridge might work fine elsewhere, but it's no match for a 110°F summer day here. You need heavy-duty commercial refrigerators and commercial freezers with compressors built to handle extreme ambient temperatures without breaking a sweat.

- Non-Stop Demand: Vegas has a sophisticated food scene, and customers expect quality and speed, even from a truck. Your cook line needs to be an absolute workhorse, capable of handling a relentless dinner rush without any drop in performance.

- Regulatory Scrutiny: The Southern Nevada Health District doesn't mess around. Every piece of essential restaurant equipment needed for success, from your three-compartment sink to your ice machine, must be NSF-certified and correctly installed. No shortcuts, no exceptions.

A food truck’s kitchen space is tight, typically just 120 to 200 square feet. This means every appliance, whether it's an undercounter fridge or a countertop fryer, has to earn its spot and perform flawlessly without wasting a single inch.

Before you start picking out appliances, let's take a quick look at the core categories you'll be working with. This table breaks down the essentials and why they're so critical for a Vegas operation.

Essential Food Truck Equipment at a Glance

| Equipment Category | Primary Function | Key Consideration for Vegas |

|---|---|---|

| Cooking Appliances | Grilling, frying, heating | Must have rapid recovery times to keep up with high-volume rushes. |

| Refrigeration | Safe food storage | Needs to be high-ambient rated to perform in extreme desert heat. |

| Food Prep Surfaces | Chopping, mixing, assembly | Stainless steel is non-negotiable for durability and sanitation. |

| Ventilation | Smoke, grease, heat removal | A powerful hood is crucial for safety and keeping the kitchen tolerable. |

| Warewashing | Cleaning and sanitizing | Must meet SNHD's specific three-compartment sink requirements. |

| Power Supply | Running all equipment | A reliable generator is key to operating anywhere, anytime. |

Getting this lineup right is the first major step toward building a truck that can not only survive but thrive in this competitive market.

Investing in a High-Stakes Market

If you're wondering whether it's worth the investment, just look at the numbers. The global food truck market is projected to hit a massive USD 4.17 billion by 2034. Here in the U.S., the roughly 48,400 trucks on the road pull in an average of $346,000 in annual revenue. That's a huge incentive for owners from Henderson to Summerlin to invest in equipment that won't let them down.

Of course, once you have the kitchen dialed in, you need to get noticed. Great food truck signage is what pulls people in off the street. This guide will walk you through building a mobile kitchen that’s truly built for Vegas—profitable, compliant, and ready for anything.

Choosing Your Core Cooking Powerhouses

Let's talk about the real heart of your food truck. It’s not the engine—it's the heat line. These are the workhorses that bring your menu to life, turning boxes of ingredients into the dishes that people will line up for. Your choice in food truck cooking equipment has a direct line to your speed, the consistency of your food, and ultimately, your bottom line.

Picture a taco truck slammed with customers on Fremont Street during a festival. Its whole operation hinges on a big, powerful griddle that can sear mountains of carne asada while warming hundreds of tortillas. Or think about a gourmet fry truck—it needs heavy-duty deep fryers that can recover heat in a flash to keep the line moving and every single fry perfectly crisp.

These powerhouses are where your concept really happens, so getting this part right is non-negotiable.

The Essential Quartet of Cooking Equipment

While menus can be all over the map, most hot food trucks are built around some combination of four key appliances. Each has a specific job, and knowing their strengths will help you build a cook line that's a perfect match for your food.

- Commercial Griddles: The undisputed MVP. A flat-top griddle is your go-to for volume and versatility, giving you a huge, even heating surface for everything from smashing burgers and toasting buns to flipping pancakes.

- Charbroilers: This is where you get that authentic, flame-kissed flavor. Charbroilers are a must for giving steaks, chicken, and burgers those killer grill marks and smoky taste. It’s how you bring the classic backyard BBQ vibe to the streets.

- Commercial Fryers: Your ticket to golden-brown perfection. From french fries and onion rings to donuts and fried chicken, a solid fryer is essential for so many popular concepts. Countertop models are a fantastic choice when space is tight.

- Ranges: The all-in-one workhorse. A commercial range gives you burners up top and an oven down below. This single piece of equipment lets you sauté, simmer, boil, bake, and roast, all in one compact footprint.

Your menu is the boss here. A burger joint might fill its space with a massive griddle and a two-basket fryer. A truck with a more complex menu, on the other hand, might need a six-burner range to pull it all off.

Think of your cooking equipment as a team of specialists. The griddle is your high-volume workhorse, the charbroiler is your flavor artist, the fryer is your texture expert, and the range is your versatile utility player. Assembling the right team for your menu is your first major strategic decision.

Gas vs. Electric: Fueling Your Fire

Once you know what you need, the next big decision is how to power it. In the food truck world, this almost always boils down to propane gas versus electricity.

Propane (Gas) Equipment is the king for high-heat, heavy-duty cooking. Your griddles, charbroilers, and fryers will almost certainly run on propane. It delivers raw, consistent power that doesn't tax your generator. This means you can crank out food during the busiest lunch rush without ever worrying about tripping a breaker.

Electric Equipment, on the other hand, is perfect for your smaller, supporting cast of appliances. Think countertop food warmers, panini presses, or maybe an induction burner for sauces. They're often easier to install and are a smart choice for gear that doesn't need the intense, non-stop heat of your main cook line.

Most successful food trucks land on a hybrid approach. They use propane for the heavy lifting and let the generator handle the electricity for refrigeration, lights, and smaller countertop gear. This balanced strategy gives you maximum cooking power right where you need it, creating a mobile kitchen that’s both resilient and efficient.

Mastering the Chill in the Desert Heat

Let’s be honest. In Las Vegas, your food truck's refrigeration isn't just another appliance—it's your MVP. When the asphalt starts sizzling and summer temps climb past 110°F, your ability to keep ingredients chilled is the only thing standing between serving amazing food and watching your profits literally melt. This is about more than just keeping things cold; it's about food safety, protecting your inventory, and sailing through your Southern Nevada Health District (SNHD) inspections.

I can't stress this enough: the desert heat puts an incredible strain on equipment. Your standard-issue refrigeration just wasn't built for this. A food truck parked on blacktop can turn into a convection oven, forcing compressors to run nonstop. That leads to burnout, spoiled food, and the kind of emergency repair bills that can sink a business. In Vegas, your commercial refrigerators and commercial freezers have to be battle-tested for extreme conditions.

Your Cold-Holding Arsenal

To run your truck with confidence, you need a few specialized pieces that work together, creating a seamless cold chain from the moment ingredients arrive to the second you serve them. Each one has a specific job to do, keeping everything in its safe temperature zone.

- Undercounter Refrigerators and Freezers: These are the absolute workhorses of your kitchen. They tuck neatly under your prep counters, saving precious floor space while keeping essentials like meats, cheeses, and prepped veggies right where you need them.

- Refrigerated Prep Tables: A total game-changer for speed and efficiency. These units give you a refrigerated base for storage and a cooled rail on top for holding pans of ingredients. If you’re running a taco or sandwich truck, a good sandwich prep table isn't just nice to have—it's non-negotiable for building a fast, safe assembly line.

- Ice Machines: In Las Vegas, an ice machine is a profit center, plain and simple. Cold drinks are a must for happy customers and a huge part of your revenue. A reliable, compact ice machine that can keep up with the rush is an investment you won't regret.

This trio is the backbone of any successful mobile kitchen in the desert. How well they perform directly impacts how quickly and safely you can serve your customers, and in a city like Vegas, that’s everything.

Features That Matter in the Vegas Heat

When you're shopping for refrigeration, remember that not all units are created equal. You have to look for specific features designed to handle high-ambient temperatures. It’s like picking a car for a desert race—you need the one with the best cooling system.

Think of your refrigeration's compressor as its heart. In the Las Vegas food truck scene, a heavy-duty, oversized compressor can handle the relentless heat of a summer day without quitting. At the same time, superior insulation acts like a shield, keeping the cold air in and the scorching heat out.

Putting your money into these robust features is a direct investment in your business’s survival. And just as important, make sure every single piece of your cold line is NSF/ETL certified. These little logos are your proof to health inspectors that your gear is safe, sanitary, and built for commercial use. It’s peace of mind in a sticker.

The importance of quality equipment is a huge deal. The global market for commercial cooking equipment hit USD 12.84 billion in 2023 and is expected to jump to USD 19.24 billion by 2032. Here in North America, the food service equipment market reached USD 10.74 billion in 2024, with core kitchen gear like grills, fryers, and refrigeration taking up a massive 36.9% slice of the U.S. market. That just shows how critical this equipment is to every single food business out there. You can learn more about the growth of the commercial cooking equipment market on globalgrowthinsights.com.

Ultimately, mastering the chill is about making smart, strategic choices. Opting for energy-efficient models can also take a huge strain off your generator and cut down your fuel costs. To get a better handle on this, you can learn more about the benefits of energy-efficient commercial refrigeration. Your cold-holding equipment is a silent partner, working tirelessly behind the scenes to make your Las Vegas food truck a success.

Designing a Workflow for Speed and Sanity

In the wild world of food trucks, your space is the most precious—and limited—resource you have. A killer layout isn't just about making things look nice; it's the invisible engine that powers your profits. Stop thinking of your truck as just a tiny kitchen. Instead, picture it as a high-performance assembly line, fine-tuned for maximum output with zero wasted movement.

A smart workflow is what separates a chaotic, cramped kitchen from a smooth, money-making machine. The whole idea is to create a logical path for your food, from raw ingredients coming out of the fridge to the finished plate being passed through the service window. Every single step should have a purpose, getting rid of the bottlenecks and clumsy movements that slow down your crew and leave customers tapping their feet.

The Blueprint for Efficiency

So, where do you start? It all boils down to one simple question: How does your food get made?

Trace the journey of your signature dish from start to finish. Once you map that out, you can strategically place every piece of your food truck cooking equipment to support each stage of the process. This isn't just a game of Tetris; it's about making every step, every pivot, and every reach count.

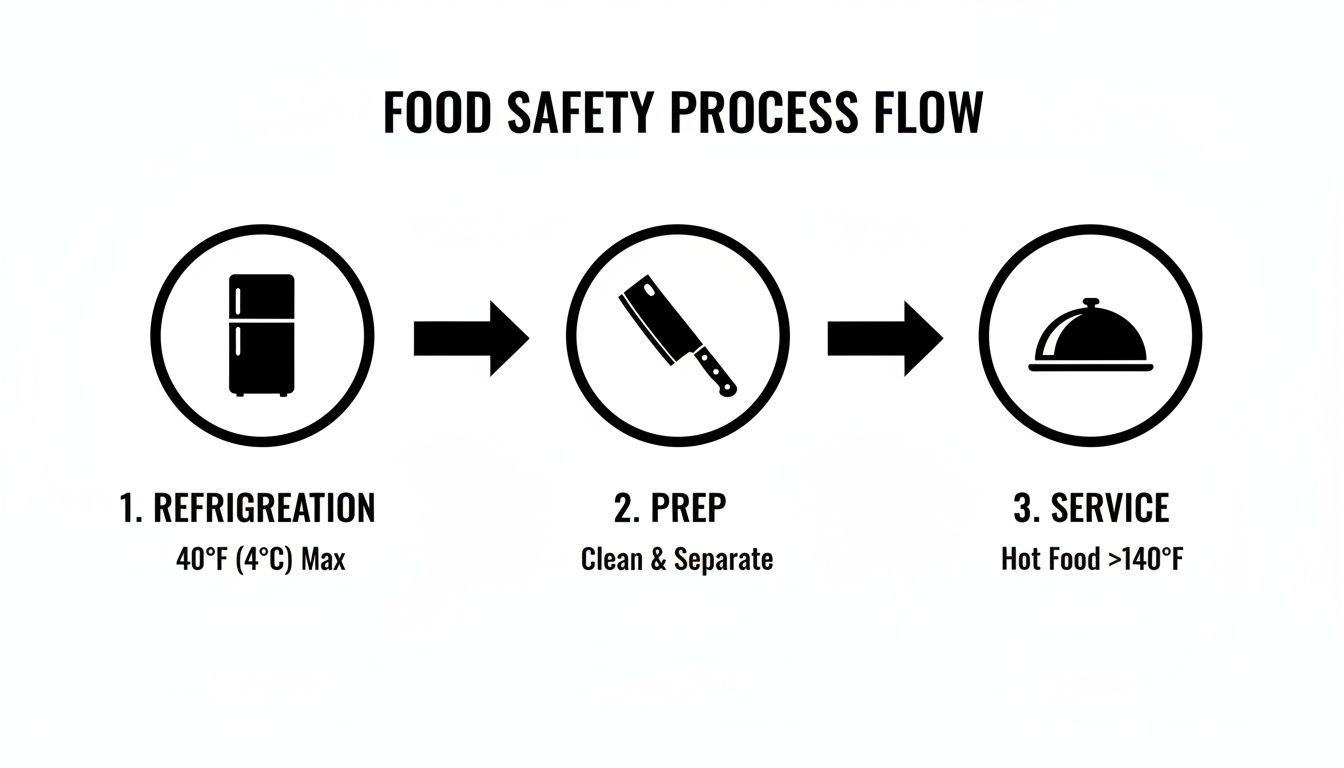

This flowchart lays out the fundamental food safety workflow that absolutely has to be the foundation of your layout.

This simple, linear path—cold storage to prep, then prep to the hot line—is the secret to a layout that's both incredibly safe and lightning-fast.

A well-planned layout is the difference between a two-person team moving in perfect sync and two people constantly tripping over each other. It directly leads to faster ticket times, which means more customers served and more money in your pocket. This is especially true during those make-or-break lunch and dinner rushes that define success in a town like Las Vegas.

For a deeper dive into the nuts and bolts, check out our guide on food truck design strategies.

Common Food Truck Layouts Comparison

Choosing the right layout is a huge first step. The table below breaks down a few common setups to help you visualize a workflow that fits your specific menu and service style.

| Layout Style | Best For (Menu Type) | Pros | Cons |

|---|---|---|---|

| Assembly Line | Tacos, Burritos, Sandwiches, Bowls | Highly efficient for linear prep; minimizes staff movement. | Can be rigid; not ideal for complex menus. |

| Galley Kitchen | General Purpose, Varied Menus | Two parallel counters create distinct work zones (e.g., hot vs. cold). | Narrow aisle can get crowded with more than two people. |

| L-Shape | Pizza, Bakeries, Coffee | Creates an open central workspace; good for one or two primary stations. | Corner space can be inefficient if not planned well. |

| Island | Gourmet/Complex Dishes | Central "command" station for the main cook; promotes teamwork. | Requires a wider truck; can create bottlenecks around the island. |

Ultimately, the best layout is the one that makes your menu happen faster and with less stress. Don't be afraid to sketch it out and walk through the motions before you commit.

Strategic Equipment Placement

Once you've mapped out your workflow, placing your equipment becomes a strategic game. It's like setting up a chessboard—every piece has a purpose and an ideal spot to support the others.

- Hot Line Location: Your main cooking gear—the griddle, fryers, and range—needs to be clustered together right under your commercial ventilation hood. This not only traps grease and smoke but also creates a dedicated "hot zone" for your cook.

- Cold Storage Proximity: Keep your commercial refrigerators and freezers, especially undercounter units and refrigerated prep tables, as close to your prep and cooking areas as you can. This cuts down on the steps your team has to take just to grab ingredients.

- Service Window Synergy: Any equipment used for the final plating and finishing touches, like heat lamps or sauce warmers, should live right next to the service window. This ensures a smooth, quick handoff to the person working the counter.

A great way to think about it is in "zones." You should have a clear area for cold storage and prep, another for cooking, and a third for finishing and service. By keeping these zones distinct but right next to each other, you create a logical flow that prevents cross-contamination and keeps everyone moving efficiently.

In a market like Las Vegas, you also have to think about local demand. The desert heat means cold drinks are a massive seller. Giving a prime, easy-to-reach spot to a high-capacity beverage cooler or an ice machine isn't just good planning—it's a direct investment in one of your biggest profit-makers. By turning your blueprint into a safe, efficient, and smart operation, you're setting yourself up for success on the bustling streets of Vegas.

Powering Your Kitchen and Ensuring On-Road Safety

All the top-of-the-line food truck cooking equipment in the world won't cook a single french fry if you can't turn it on. The technical backbone of your truck—its power and safety systems—is the invisible engine that keeps your business running. This isn’t just about flipping a switch; it's about building a tough, reliable, and compliant mobile kitchen that can handle the intense demands of a city like Las Vegas.

Think of it this way: your truck’s power system is its central nervous system. A powerful generator is the brain, sending electricity to your refrigerators and small appliances. Your propane system is the muscle, fueling the raw heat for your griddles and fryers. If either one gives out during a dinner rush, your entire operation grinds to a halt.

Sizing Your Generator for Peak Performance

Picking the right generator is one of the most critical decisions you'll make. If you go too small, you'll be tripping breakers constantly and putting your expensive equipment at risk of damage. Go too big, and you're just burning fuel and money for no reason. The secret is to do the math and calculate your electrical load accurately.

First, make a list of every single piece of electrical equipment you plan to use. For each item, you need to find two numbers:

- Running Wattage: The power an appliance needs to operate continuously.

- Starting Wattage: The extra jolt of power required to start up motors and compressors. This can be 2-3 times higher than the running wattage.

To figure out your total need, add up the running wattage of everything you'll have on at the same time. Then, find the single highest starting wattage from your list and add that to your total. This final number is the absolute minimum power your generator needs to deliver.

As a rule of thumb, always buy a generator with about 20-25% more capacity than your calculated minimum. This buffer is your safety net. It prevents overloads, gives you room to add more equipment later, and keeps your generator from running at full blast all day, which will dramatically extend its lifespan.

The Power of Propane

While the generator handles all your electrical gear, propane is the undisputed champion for fueling your heavy-duty cooking appliances. It delivers the intense, consistent heat your griddles, fryers, and ranges need without putting a single watt of strain on your electrical system. This hybrid setup—electricity for cooling and smalls, propane for cooking—is the industry standard for a reason. It creates a balanced, powerful, and incredibly efficient mobile kitchen.

Of course, working with propane means you have to follow safety rules to the letter. Professional installation is non-negotiable. Your system must have securely mounted tanks, proper ventilation, and easy-to-access shut-off valves. You can bet that fire marshals in Las Vegas and Henderson will be inspecting these systems with a fine-toothed comb.

Mandatory Safety Systems for Las Vegas Compliance

Beyond just power, two critical safety systems are absolutely required to operate legally and safely: a commercial ventilation hood and an integrated fire suppression system. These are not optional upgrades; they're the heart of your truck's safety and the first thing inspectors look for.

- Commercial Ventilation Hood: This is your first line of defense. It sucks hot, grease-filled air, smoke, and steam right out of your kitchen. This keeps the air clean and safe for your crew and drastically reduces the risk of a dangerous grease fire.

- Fire Suppression System: This automated system is installed directly inside your ventilation hood, with nozzles aimed at your cooking appliances. If a fire ever breaks out, it automatically floods the area with fire-suppressing chemicals to extinguish the flames in seconds.

The U.S. food truck market is exploding, projected to hit USD 1.59 billion by 2031. This growth is powered by a national fleet of 48,400 trucks, with each one generating an average of $346,000 a year. The West is leading the charge, and suppliers like Las Vegas Restaurant Equipment are here to provide the compliant, durable gear—from stainless steel interiors to electric refrigeration—that Nevada’s casinos and thriving food trucks depend on. You can dig into more insights about the booming U.S. food truck market on mordorintelligence.com.

The smartest way to guarantee you meet these tough safety standards from day one is to ensure every piece of equipment, from your generator to your fryer, is NSF and ETL certified. These certifications are your proof that the equipment is built for commercial use, is safe to operate, and will pass inspection. That leaves you free to focus on what really matters—serving amazing food.

Getting Your Equipment on the Truck Without Breaking the Bank

Okay, you've got your perfect equipment list. Now for the fun part: turning that list into a real, working kitchen on wheels. This is a huge step, and making smart choices here is what separates the trucks that thrive from those that just survive. It's all about outfitting your mobile kitchen without torching your budget right out of the gate.

The first big question is always: new or used? Look, I get the appeal of used gear—the lower price tag is tempting. But I've seen it go wrong too many times. New equipment brings something far more valuable to the table: a manufacturer's warranty. That piece of paper is your safety net. When your brand-new fryer decides to act up, you're covered. That kind of peace of mind is priceless when a single dead appliance can shut you down for the day.

Smart Ways to Buy and Finance in Today's World

The good news is, you don't have to choose between quality and affordability anymore. Modern suppliers have changed the game. By skipping the expensive physical showrooms and operating online, they can offer the same top-tier brands at much better prices. They cut their overhead, and you pocket the savings. A lot of them even throw in fast, free shipping, so your new gear shows up at your door without any surprise fees.

Of course, the biggest hurdle for most new owners is coming up with the cash. But here's the thing: you don't need a mountain of it to get started. There are fantastic financing options built specifically for food truck entrepreneurs. You can get the professional-grade equipment you need now and pay it off over time, which keeps your precious starting capital free for other essentials like your first food order, marketing, and permits.

Investing in reliable, compliant equipment from the start isn't just an expense; it's a strategic move. New, warrantied gear minimizes the risk of costly downtime and ensures you pass health and fire inspections in Las Vegas without any issues, protecting your revenue from day one.

And don't forget, beyond the big cooking appliances, you need a way to get paid! A clunky payment process can kill your lunch rush, so make sure to research the best mobile POS systems to keep the line moving and the money flowing.

Knowing your financial options is a game-changer. To get a really clear picture of how you can fund your dream kitchen, check out our complete guide to food truck equipment financing. This is the knowledge that empowers you to build your truck with durable, high-performance gear, setting you up for success from the moment you slide open that service window.

Your Food Truck Equipment Questions Answered

Stepping into the world of mobile kitchens can feel like a maze, especially in a market as demanding as Las Vegas. The city’s famous restaurant scene doesn't cut you any slack just because you're on wheels—the pressure for top quality and speed is real. Let's cut through the noise and get you clear, no-nonsense answers to the questions we hear from food truck owners every day.

What Are the Most Important Certifications for Food Truck Equipment in Las Vegas?

You'll want to get very familiar with two acronyms: NSF and ETL. Think of them as your golden tickets for passing inspections.

NSF (National Sanitation Foundation) is all about public health. This sticker tells the Southern Nevada Health District that your equipment is designed to be easily cleaned and sanitized, preventing foodborne illness. On the other side, the ETL mark (from Intertek) is about safety—it certifies that your appliances meet North American standards for electrical and gas hookups. Having both is non-negotiable for getting the green light from health and fire inspectors anywhere from Summerlin to Henderson.

How Do I Choose the Right Size Generator for My Truck?

Picking the right generator is less about guesswork and more about simple math. Start by making a list of every single piece of electrical equipment you have. For each one, find its starting wattage (that initial burst of power it needs to turn on) and its running wattage.

Add up the running wattage for all the gear you'll be using at the same time. Then, find the single highest starting wattage on your list and add that number to your total. As a final buffer, grab a generator with about 20% more capacity than that final number. This little bit of extra power keeps you from tripping breakers during a rush and helps your generator last a whole lot longer.

Should I Use Propane or Electric Cooking Equipment?

Why not both? The smartest and most common setup for a successful food truck is a hybrid system.

Let propane handle the heavy lifting. Your griddles, fryers, and ranges need a ton of consistent heat, and propane delivers that raw power without bogging down your generator. Save your precious electrical capacity for things like your commercial refrigerators, food warmers, lights, and POS system. This balanced approach gives you the best of both worlds: intense cooking power and a stable, reliable electrical load.

A hybrid power system is the industry standard for a reason. It leverages the raw power of propane for intense cooking while dedicating your generator's electrical output to the essential tasks of refrigeration and auxiliary functions, creating a resilient and efficient mobile kitchen.

How Does the Las Vegas Heat Impact My Refrigeration Needs?

That desert sun is no joke, and it’s absolutely brutal on refrigeration units. This is one area where you simply cannot cut corners. You need to invest in true commercial-grade refrigerators and freezers built with heavy-duty compressors and top-notch insulation. Look for units specifically rated for high-ambient temperatures.

Trying to save a few bucks on a cheaper unit is a recipe for disaster. It will lead to spoiled food, failed health inspections, and a busted compressor on the hottest day of the year. Just as important, make sure your truck layout includes plenty of ventilation around your commercial freezers and ice machines. Giving them room to breathe is crucial for them to run efficiently and survive the Vegas heat.

For all your new, warranty-backed food truck cooking equipment needs, trust Las Vegas Restaurant Equipment to deliver reliable, compliant, and competitively priced gear right to your door. Explore our selection online at https://lasvegasrestaurantequipment.com.