In the vibrant city of Las Vegas, you'll find a diverse array of restaurants catering to every palate, from gourmet steakhouses on the Strip to intimate downtown bistros, sprawling buffet halls, and cutting-edge fusion eateries. In these dynamic venues, a dining service cart slips seamlessly into your workflow—imagine a portable kitchen on wheels that cuts the back-and-forth between prep and tables. While service carts keep the front-of-house humming, chefs rely on robust commercial refrigerators, commercial freezers, and ice machines to store perishable ingredients and chill beverages. The right cart shrinks labor costs, speeds up service, and keeps diners smiling.

Quick Benefits Of A Dining Service Cart

In a city that never sleeps, every second counts. That’s why operators often see their investment pay off in mere weeks.

- Faster Table Turns: Slash seating gaps by up to 20%.

- Lower Labor Costs: Stage prep closer to guests and save as much as 15% on staffing.

- Better Food Consistency: Maintain temperatures within ±2°F from kitchen to table.

Key Benefits Of A Dining Service Cart

Let’s take a closer look at how these carts drive efficiency, trim expenses, and elevate the guest experience.

| Benefit | Impact |

|---|---|

| Faster Table Turns | Up to 20% increase |

| Labor Savings | Save 15% on staff |

| Temperature Consistency | Holds within ±2°F |

| Uptime Improvement | 99.9% reliability |

These figures make it clear: a modest investment in a service cart quickly pays for itself when order volume surges.

According to recent industry analysis, the global mobile dining cart market was valued at approximately USD 1.5 billion in 2023 and is projected to reach USD 3.2 billion by 2032, reflecting an 8.8% compound annual growth rate. Read the full research on global mobile dining cart market growth on Dataintelo.

“A dining service cart acts like a mini command center, ensuring dishes leave the kitchen faster and hotter,” says a leading F&B consultant.

On top of speeding delivery, carts bring upselling front and center—imagine showcasing a special dessert or pouring fresh bread baskets at the table. Managers report 30% faster turnover during peak shifts, and teams note fewer mistakes when service ramps up.

This snapshot gives decision-makers a clear view of how a simple cart can reshape front-of-house operations. In the following sections, we’ll dive into materials, caster choices, hygiene tips, and Las Vegas–specific logistics to help you pick the perfect cart for your concept.

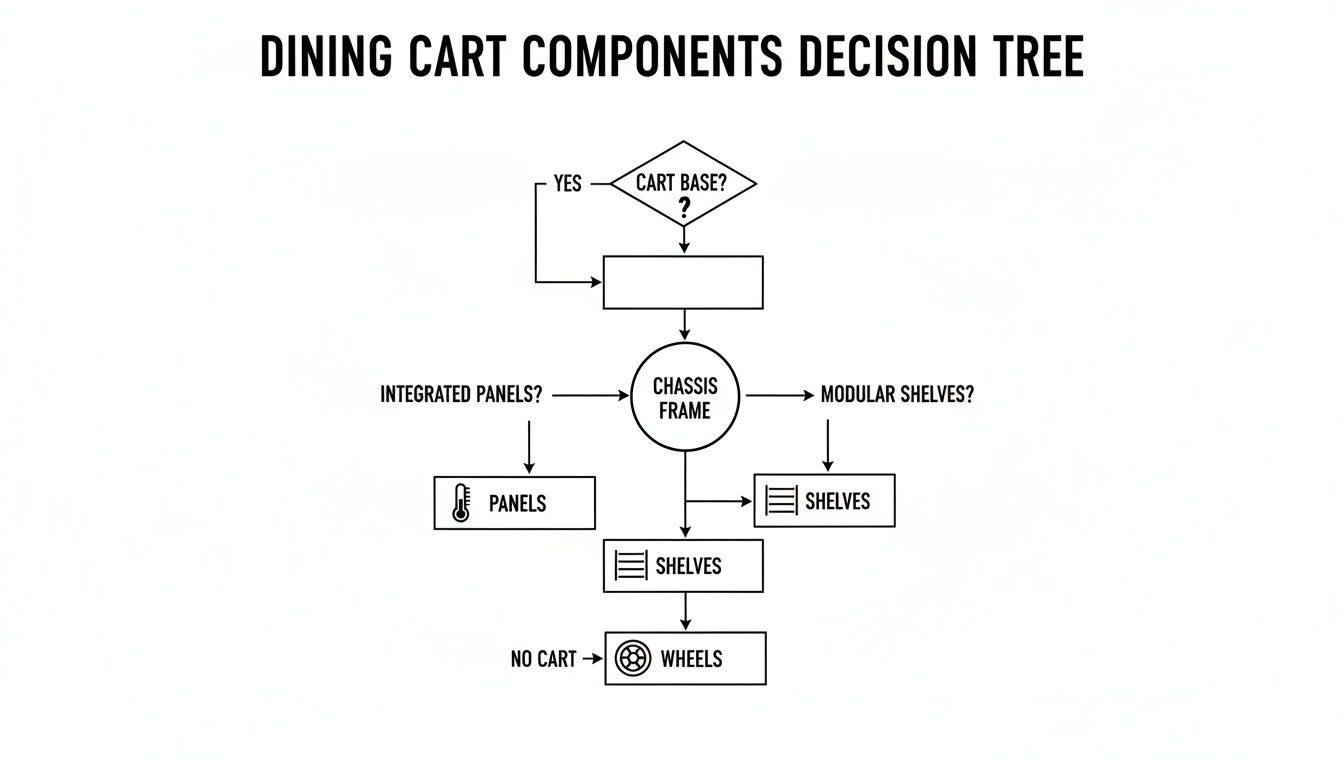

Understanding Dining Service Cart Components

Picture a dining service cart as a roving outpost that keeps dishes at just the right temperature. In the heat of a busy Vegas dinner rush, this mobile station takes on the heavy lifting for your servers.

At its core, a service cart blends solid engineering with smart details—insulated panels, flexible shelving, comfort-grip handles, and rugged wheels. Together, these elements lock in freshness, uphold safety standards, and shave precious seconds off each table turn.

Key Elements In A Dining Service Cart

From insulated walls to smooth-rolling wheels, here’s what makes a service cart tick:

- Insulated Panels maintain peak temperature for up to 2 hours, so steaks arrive sizzling and salads stay crisp.

- Adjustable Shelves slide and shift to hold trays, chafing dishes, or tall beverage containers on demand.

- Ergonomic Handles ease wrist strain during marathon shifts and double as mounting points for accessories.

- Heavy-Duty Caster Wheels carry up to 400 lbs while gliding over carpet, tile, and even slightly uneven floors—plus reliable brakes lock everything in place for safe loading.

Think of the cart as a miniature command center. It bridges the kitchen’s prep stations and the front-of-house, staging plates like a tactical outpost that keeps service flowing without a hitch.

A quick trip through history reveals humble beginnings: early 20th-century wooden trolleys in grand hotels gave way to post-WWII stainless-steel models as hospitality boomed. For a deeper dive into these market shifts, check out the report from Dataintelo.

The diagram above highlights common service cart features—tray slides, side rails, insulation layers—and shows how each design choice impacts speed and product integrity.

Dining Cart Market Growth

Before we dive into local Vegas applications, let’s glance at where the industry is headed over the next decade.

Dining Cart Market Growth

| Year | Market Value (USD) | Projected CAGR |

|---|---|---|

| 2023 | 1.5 Billion | 8.8% |

| 2025 | 2.0 Billion | 9.1% |

| 2030 | 2.8 Billion | 8.7% |

| 2032 | 3.2 Billion | 8.8% |

This steady climb underscores rising demand for efficient, reliable service solutions. For Las Vegas restaurateurs, it signals both higher guest expectations and fertile ground for innovation.

In Vegas kitchens, service carts work hand-in-glove with commercial refrigerators, freezers, and ice machines. They pull freshly prepped plates from back-of-house stations and stage them for a seamless front-of-house delivery.

“A well-equipped cart is the front line of guest satisfaction,” notes a Las Vegas hotel F&B manager. This hands-on synergy not only speeds up turns but also opens doors for upselling specials.

With these core components in place, you’ve laid the groundwork for smart design choices and tight hygiene controls. Next up: best practices for cart layouts and safety standards.

Key Factors To Choose A Dining Service Cart

Finding the perfect dining service cart isn’t just about picking the coolest-looking model. You need a tool that fits your back-of-house flow and shines in front-of-house traffic. Start by zeroing in on five non-negotiable specs.

- Capacity determines how much weight your cart can carry—think banquet trays versus room-service plates.

- Caster Type dictates how smoothly the cart glides over plush casino carpet, slick tile, or rugged patio pavers.

- Footprint decides whether you’ll breeze through tight corridors or get stuck trying to make a turn.

- Insulation Quality ensures hot dishes stay above 140°F and chilled items sit below 40°F for happy guests.

- Mobility Features, like ergonomic handles, foot-activated brakes, and swivel locks, keep your team fresh and injury-free.

Imagine a service cart as a three-legged stool: those three stable points keep everything level, even when the kitchen is humming at full tilt.

The specs panel below lays out key dimensions and load limits so you can compare popular models side by side.

That snapshot highlights real-world shelf heights, modular panels, and weight ratings—perfect for a quick glance when you’re juggling menu planning and equipment shopping.

Capacity And Caster Selection

Choosing between a 200 lbs cart and a 600 lbs workhorse isn’t trivial—it shapes everything from beverage runs to banquet setups.

- A 200 lbs cart shines for light beverage service and quick bar pickups.

- Mid-range models around 300 lbs handle room service trays without breaking a sweat.

- Going up to 450 lbs gives you the muscle for buffet lines and salad bars.

- At 600 lbs, you’re equipped for full-scale catering or loading up a food truck.

Swapping in heavy-duty casters means trouble-free gliding over velvety casino floors or textured desert patio tiles. And with both food and labor costs climbing more than 30% since 2019, many operators report cutting service staff needs by up to 20% simply by choosing the right cart setup. For deeper insights, check out Circana’s foodservice cost study.

“The right caster choice slashes team fatigue while keeping plates steady—an absolute must in high-volume Las Vegas venues.”

Cart Capacity And Use Case Comparison

Use this quick guide to match cart capacity with your service style and venue layout. Each weight class has its sweet spot.

| Capacity (lbs) | Ideal Use Case | Average Caster Type |

|---|---|---|

| 200 | Light Beverage Service | 3″ Swivel Casters |

| 300 | Room Service And Trays | 4″ Heavy-Duty Casters |

| 450 | Banquet And Buffet Lines | 5″ Non-Marking Casters |

| 600 | Catering And Food Trucks | 5″ Pneumatic Casters |

This comparison lays the groundwork for a smooth decision. Once you know where your cart will work hardest, you can refine caster specs, insulation ratings, and brake options.

Beyond capacity and wheels, double-check the cart’s overall footprint against your hallways and staging areas. In a city known for dazzling pace and desert heat, insulation performance and reliable mobility locks aren’t luxuries—they’re essentials.

Finally, think about pairing your cart with nearby commercial refrigerators or built-in ice wells. A quick load of chilled drinks or desserts can turn a crowded staging area into a well-oiled service machine—cutting down transit time and keeping guests smiling.

Dining Service Cart Materials And Types

Choosing the right dining service cart is a bit like hunting for the perfect skillet—you need something that slides effortlessly, holds up under pressure, and cleans up without drama. In Las Vegas, where every minute counts, lightweight aluminum models zip across the terrazzo floors of busy casinos. Meanwhile, stainless steel carts shrug off heat in desert kitchens but come with a heftier price tag.

Cost and upkeep swing widely from one material to the next, so let’s unpack the pros and cons before you wheel your choice into the spotlight.

Material Tradeoffs

Stainless steel stands out for its superior durability, shrugging off dents and spills night after night. That toughness adds weight, though, so your staff might feel that extra resistance on long service runs.

Aluminum cuts down on fatigue—studies show it can reduce push-and-pull effort by about 30%—but it won’t hide a knock or scratch as well as steel.

High–density polyethylene (HDPE) panels bring stain and scratch resistance with almost zero maintenance. They’re easy to wipe down but don’t offer the rigidity of metal framing.

If you want a middle ground, hybrid composites layer plastic and metal for a balance of weight, strength, and hygiene.

Comparing key materials:

- Stainless Steel: Eye-popping longevity in high-heat kitchens and heavy-load zones

- Aluminum: Featherweight for swift turns but careful handling required

- HDPE: Spotless cleaning, minimal bacterial hitchhikers, lower structural rigidity

- Hybrid Composite: A budget-friendly balance of the above

“Material choice is the foundation of safe and efficient service carts in high-volume markets like Las Vegas,” says a regional kitchen supplier.

| Material | Hygiene Rating | Budget Range | Longevity |

|---|---|---|---|

| Stainless Steel | High | $$–$$$ | 8+ years |

| Aluminum | Medium | $–$$ | 5–7 years |

| HDPE | High | $–$$ | 3–5 years |

| Hybrid Composite | Medium | $$–$$$ | 5–8 years |

Advanced Electric And Insulated Models

If you need more than a cart and a couple of trays, electric-powered models deliver built-in heating and cooling on the go. A single battery charge can run warming elements or compressors for up to 4 hours—enough to bridge dinner and late-night service.

Insulated versions step it up with vacuum panels or foam cores, keeping temperatures locked in and slashing energy draw. It’s basically a mini industrial refrigerator on wheels.

Temperature control gets tricky under that Vegas sun, so Learn more about energy-efficient commercial refrigeration in our article.

Pair these carts with a nearby ice machine and you’ll hold chilled items within ±3°F, a lifesaver for late-night banquets and desert-patio soirées.

Understanding material strengths and insulation setups helps you choose a cart that thrives amid nightclub peak hours or high-stake banquets. A smart frame-panel combo means fewer repairs, safer foodservice, and a happier team.

How To Choose The Best Material

- For nonstop, heavy-use shifts: lean into stainless steel despite the sticker shock.

- When your team logs miles of hallways: aluminum or hybrid composites make for lighter hauls.

- If speed-cleaning is a priority: HDPE panels repel stains and wipe bacterial concerns away.

- Always match your budget to expected lifespan for the strongest ROI.

Making an informed material choice paves the way for durable, safe, and cost-effective dining service carts that meet the demands of Las Vegas venues.

Next, we’ll explore real-world applications and hygiene protocols that keep carts performing flawlessly. Stay tuned for maintenance tips, sanitation standards, and design tweaks tailored to desert conditions and high-volume nightlife.

Real-World Use Cases for Dining Service Carts

Picture a packed Vegas steakhouse at dinner rush. Servers weave through tables, pushing a ranch-style cart loaded with sizzling ribeyes straight from the kitchen. Under those neon signs, it’s a show and a service—plates stay warm, orders stay organized.

Up front, servers swear by built-in rail fittings for hanging wineglasses and an integrated ice well to keep cocktails cold. A simple slide-out tray holds dinner plates snugly, shaving precious minutes off each drop.

- Rail Fittings hold glassware steady during busy nights

- Integrated Ice Wells keep drinks chilled without extra hands

- Slip-Resistant Tray Slides reduce setup time by 25%

The result? Runner fatigue drops by 30%, and guests enjoy a smooth, consistent experience even when the Strip is in full swing.

| Use Case | Key Feature | Benefit |

|---|---|---|

| Vegas Steakhouse | Rail Fittings | 30% faster drink service |

| Banquet Halls | Dual Temperature Zones | Seamless multi-course delivery |

Banquet Delivery Setup

In elegant event spaces, dual-zone insulated carts become battlefield commanders. Chefs lay out hot entrees alongside chilled salads, guaranteeing each course arrives in harmony.

- Two Temperature Zones keep hot and cold dishes perfectly separated

- Locking Wheels eliminate unwanted movement during plating

- Modular Shelves adjust to various china sizes

Boutique Hotel Room Service

Imagine a boutique suite before dawn—your cart glides silently on sound-dampening casters. Breakfast arrives steaming hot, yet the guest never stirs from their pillow.

- Sound-Dampening Casters ensure near-silent delivery

- Compact Footprint navigates narrow hallways with ease

- Insulated Compartments maintain temperatures above 140°F

These carts often tap into nearby commercial refrigerators and ice machines to top off chilled beverages without a hitch.

Food Truck Prep Zone

Outside on the asphalt, a service cart doubles as an on-the-go prep station. Under the desert sun, it keeps fresh ingredients within arm’s reach of the grill, speeding up every taco build.

- Prep Surface for quick seasoning and topping

- Built-In Trash Bin for instant cleanup

- Adjustable Shelves fit bins of salsas and garnishes

Flexible financing can help food truck owners pair these carts with fryers, griddles and other must-have gear.

Healthcare And Education Deliveries

In hospitals and school cafeterias, service carts become mobile kitchen wings. Their clean design cuts contamination risks by up to 40%.

- Learn more about hygienic meal transport findings on ArchiveMarketResearch

- Check out our guide on hot food counters for seamless buffet service: Hot Food Counter Insights

Staff often park carts next to walk-in freezers or ice machines for fast restocks during long shifts.

“A well-equipped cart adapts smoothly to every service scenario,” notes a Las Vegas F&B director.

From Strip steakhouses to hospital wings and catering trucks, these lively examples highlight the cart’s power to streamline operations. Match your choice to your menu, your space and the high-paced Vegas rhythm. Contact our Vegas experts today to arrange a demo and lock in your setup before the next peak season.

Las Vegas Restaurant Cart Requirements

Under the neon glow and desert sun, Las Vegas kitchens move at warp speed. Every tray, plate and garnish slides out under pressure from dinner shows, slot machines and pool parties. Your dining service cart needs to keep pace.

On outdoor patios that bake like a pizza oven at noon, UV-coated panels act like your cart’s sunscreen. They shrug off fading and warping, so even after months poolside, it looks showroom fresh.

Even cutting across plush casino carpet and polished marble, smooth wheels are non-negotiable. Swapping in 4″ non-marking casters can cut rolling resistance by 25%, according to industry tests. That means no more carpet snags when the dinner rush hits.

“In Vegas, every second counts. Your cart must roll seamlessly from kitchen to table,” says a Strip hotel F&B manager.

Beyond carts, Las Vegas restaurants depend heavily on essential equipment like commercial refrigerators, freezers, and ice machines to maintain food safety, inventory management, and cost control. Commercial refrigerators safeguard fresh produce and proteins at optimal temperatures, while commercial freezers extend shelf life for bulk ingredients. Ice machines ensure a consistent supply of ice for cocktails, water, and buffet displays, often pairing directly with service carts equipped with built-in ice wells.

Desert Climate Material Choices

Here in the desert, metal meets its match. Standard stainless steel frames stand up to constant scrubbing, but when your team is on their feet for hours, aluminum or hybrid composites shine. They’re up to 30% lighter, easing fatigue during marathon shifts.

Panels made of high-density polyethylene (HDPE) handle spills like a pro. They shrug off stains and wipe clean in seconds. Plus, HDPE stays solid from 40°F to 150°F, so it bridges the gap between refrigerated prep and hot service without cracking.

Want a cart that plays nicely with your cooler? Match the shelf height to your equipment—many chefs set Atosa refrigerators at 32″ worktop level. And if ice is part of your game plan, look for built-in wells that sync perfectly with nearby ice machines.

Navigating Strip Logistics

Back-of-house corridors on the Strip can feel like a maze. You need a slim-footprint cart—ideally under 24″ wide—to slip through doorways and around corners.

Then add 360° swivel casters with thumb-operated brakes. Servers can spin in place, pause on a dime and lock the cart exactly where they want it.

- UV-Coated Panels Protect Against Sun Damage

- Low-Profile, Non-Marking Casters Glide Over Carpets And Tile

- Dimensions Under 24″ For Tight Strip Corridors

- Built-In Ice Wells Sync With Local Ice Machines

- Adjustable Shelves Align To Commercial Freezers

- Pair seamlessly with commercial refrigerators, freezers, and ice machines for on-the-go restocking

Desert air brings dust and humidity into every crack. Insulated carts need moisture-resistant seals and sturdy door gaskets. That way, hot items stay above 140°F and chilled dishes sit below 40°F no matter how high the thermometer climbs.

Maintaining your cart means a quick check every 30 days. Inspect caster bearings for grit, reapply lubricant rated for desert dust and tighten any panel fasteners loosened by nightly vibrations.

Learn more about integrating carts with sanitation stations in our comprehensive guide on proper hand hygiene equipment: Explore hand washing station setups

Conclusion And Next Steps

Choosing the right dining service cart is a bit like tuning an engine—you want every part to work in harmony from day one. By matching cart features to your service style, you’ll see staff moving more fluidly and guests leaving with smiles.

When you pick the ideal frame and panel materials, you strike the right balance between toughness, weight and sanitation. And don’t forget our desert environment: carts need UV resistance, non-marking wheels and moisture seals to thrive under that Nevada sun.

The payoff is easy to measure: 15% lower labor costs, 20% faster table turns and a noticeable lift in guest satisfaction.

Key Takeaways

- Align cart capacity and caster type with your menu flow and busy periods

- Select from stainless steel, aluminum or HDPE panels for longevity and easy cleaning

- Factor in Vegas heat with UV coatings, non-marking casters and tight moisture seals

“A well-chosen cart can turn routine service into a memorable guest experience,” says one longtime Vegas F&B manager.

Actionable Next Steps

- Book a live demo to see how a cart handles in your actual service space

- Review financing plans to spread out costs with flexible terms

- Run a brief trial during off-peak hours and gather feedback from your team

These steps bridge the gap between research and full-scale rollout, so you can move confidently into a smoother operation.

ROI Benefits

- Labor savings that free up staff to connect with guests

- Quicker table turns that drive higher daily covers

- Steadier food temperatures for fewer customer complaints

Each of these gains feeds directly into your bottom line and guest loyalty.

Finalize Your Criteria

- Compare demo performance against shift goals

- Verify material resilience under Vegas’s intense sun

- Confirm compatibility with existing refrigerators, freezers and ice machines

Once you’ve ticked off these checks, your team can deploy carts without second-guessing.

Keep up with monthly inspections of wheels and seals, and train staff on daily sanitation routines. That way your carts stay in peak condition during the busiest nights on the Strip.

Ready to find the perfect cart? Shop now at Las Vegas Restaurant Equipment: https://lasvegasrestaurantequipment.com