Think of a hot food counter as the crucial handover point between your kitchen's hard work and a happy customer. It's the specialized piece of gear built to hold your cooked food at perfectly safe, consistent, and frankly, delicious-looking temperatures. In the vibrant city of Las Vegas, where a diverse array of restaurants caters to every palate, this equipment is the non-negotiable heart of the operation for any buffet, cafeteria, or quick-service spot.

This isn't just a warmer. It's a merchandising powerhouse that keeps your menu looking and tasting like it just came off the line.

The Heartbeat of Las Vegas Service Lines

In the wild, competitive food scene here in Las Vegas, you win or lose on speed, quality, and how good your food looks. From the massive buffets on the Strip to the cool fast-casual joints popping up in Henderson, a hot food counter is so much more than a piece of steel—it's the main event of your service line.

Consider it your best, most reliable salesperson. It works nonstop, showing off your culinary creations and guaranteeing every single dish is served at a safe and appetizing temperature.

This one piece of equipment has a direct line to your customer satisfaction and your bank account. A clean, well-lit, and perfectly organized counter pulls people in. A sad, poorly managed one serves up cold food and kills your revenue. In a city that truly never stops, you can't afford a weak link in your service line.

Essential Partners in a High-Functioning Kitchen

Your hot food counter is a team player; it can't do its job alone. Its success depends entirely on the other key players in your kitchen, all working together to create a smooth flow from the walk-in to the customer's plate. For any Las Vegas restaurant serious about running a tight ship, this support system is everything. To succeed, you must explore the essential restaurant equipment needed.

Here are the key pieces that work hand-in-hand with your hot holding station:

- Commercial Refrigerators: This is where quality begins. Your refrigerator keeps ingredients fresh and safe before they’re even prepped. A solid commercial fridge ensures the journey from cold storage to the hot counter starts with the best possible product.

- Commercial Freezers: Absolutely essential for bulk storage and smart menu planning. Commercial freezers let you manage inventory like a pro, making sure you always have a steady supply of ingredients ready to go for the line.

- Ice Machines: In the Las Vegas heat, an ice machine is a lifeline. They're usually right next to the service lines for a reason, keeping drinks ice-cold to perfectly complement your hot dishes and give guests the full experience.

At the end of the day, your hot food counter is the final checkpoint where all your kitchen's effort meets the customer. When you pair it with reliable cold storage and beverage equipment, you create a powerful system that keeps service humming, even during a slammed Saturday night dinner rush. Getting this setup right is how you build a reputation for quality and speed in this town.

Exploring Different Hot Food Counter Technologies

Picking the right heating technology for your hot food counter is one of the most important calls you'll make for your Las Vegas spot. It's a decision that directly affects the quality, texture, and safety of every plate you send out. Think of it like a chef choosing a cast-iron skillet for a perfect sear versus a saucepan for a delicate sauce—you have to match the tool to the job.

The demand for great food display equipment is huge and only getting bigger. The global market, sitting at USD 2.4 billion back in 2025, is expected to climb to USD 3.5 billion by 2035. With the USA kicking in over 33% of that, it’s clear that presentation and quality are king in this industry.

Steam Heat for Moisture-Rich Dishes

A steam table, often called a bain-marie, is basically a gentle, humid sauna for your food. It works by using a tank of hot water to create steam, which then wraps around your food pans. This moist heat is absolutely perfect for dishes that need to stay hydrated and can't afford to dry out over a long lunch or dinner rush.

This is the go-to method for so many Las Vegas buffets and cafeterias, and for good reason. It’s ideal for:

- Sauces and Gravies: Keeps them from forming that unappealing skin on top and maintains a perfect, pourable consistency.

- Mashed Potatoes and Macaroni and Cheese: The humidity is key to keeping these comfort-food champs creamy and delicious for hours.

- Steamed Vegetables and Pasta: The gentle heat holds their texture and moisture without turning them to mush.

For anything delicate that would otherwise break down quickly, a steam-based counter is a lifesaver.

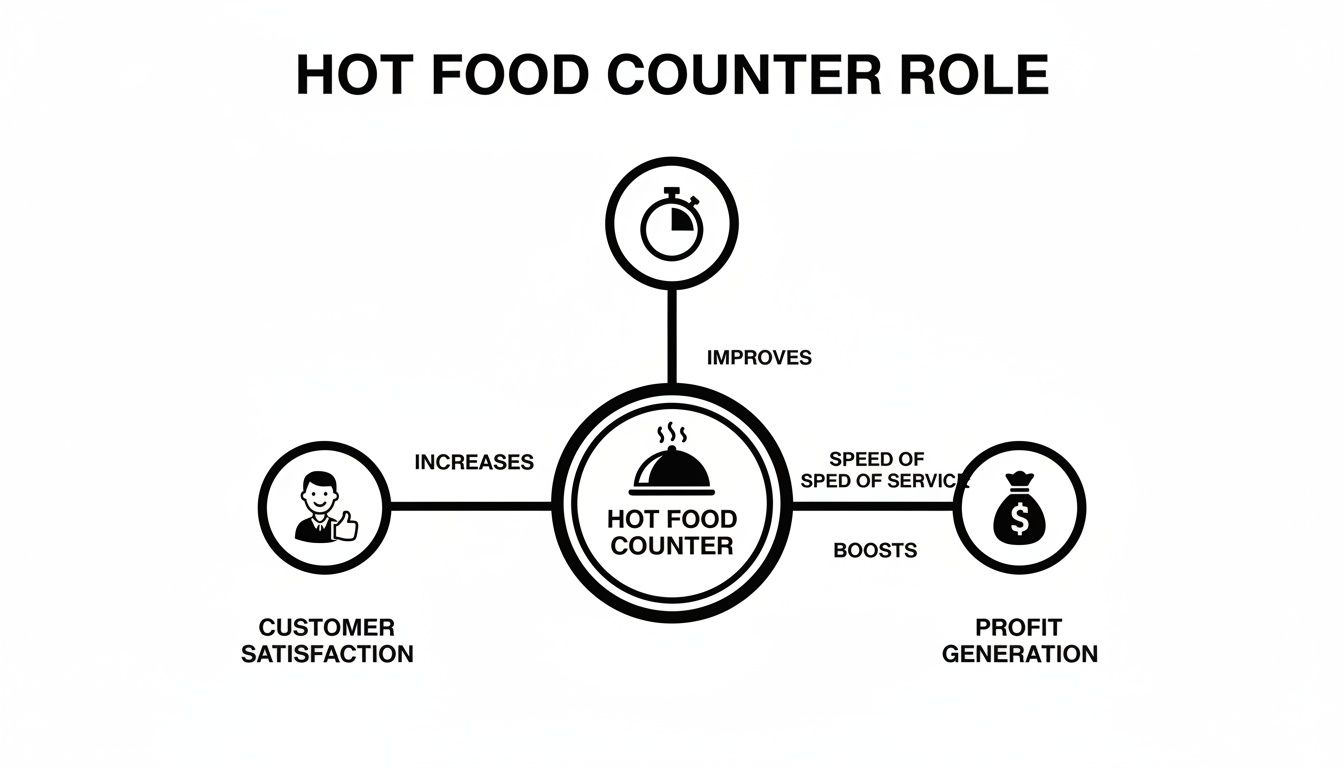

As you can see below, a hot food counter isn't just a box that keeps things warm; it's a central piece of the puzzle for hitting your operational goals.

This diagram really drives home how the unit is a critical tool that directly impacts your service speed, customer happiness, and bottom line.

Dry Heat for Crispy and Fried Foods

On the flip side, a dry heat well works more like a low-and-slow oven. Instead of water, it uses heating elements—either exposed or enclosed—to send radiant heat straight to the food pans. This is the only way to go for anything on your menu that needs to stay crispy and crunchy.

A classic rookie mistake is putting fried food in a steam table. All that moisture will turn a perfectly crispy coating into a soggy, sad mess in minutes. Dry heat is non-negotiable for preserving that crunch customers crave.

Dry heat is your best friend for:

- Fried Chicken and French Fries: It keeps the outside perfectly crisp without steaming the breading from the inside out.

- Roasted Meats: Helps that beautiful, delicious crust you worked so hard to create stay just right.

- Baked Goods: Items like dinner rolls or pieces of cornbread stay warm without getting damp and heavy.

Many of the smartest kitchens in Vegas use a mix of both. You’ll often see a service line with a steam table holding saucy entrees and sides, right alongside a dry heat unit keeping the fried chicken crisp. This hybrid setup gives you the flexibility to handle almost any menu.

Before we get into the nitty-gritty of choosing, let's break down the core differences between these two heating methods.

Comparing Hot Food Counter Heating Technologies

Choosing between steam and dry heat really comes down to your menu. One preserves moisture beautifully, while the other is essential for maintaining crispiness. This table lays out the key differences to help you decide what's right for your kitchen.

| Feature | Steam Heat (Bain-Marie) | Dry Heat (Heated Wells) |

|---|---|---|

| Best For | Moisture-rich foods: sauces, pasta, mashed potatoes, steamed veggies | Crispy/fried foods: fried chicken, fries, roasted meats, bread |

| Heat Transfer | Gentle, moist heat via steam from a water pan | Direct, radiant heat from electric elements |

| Texture Impact | Keeps food moist and prevents drying out | Maintains crispiness and prevents sogginess |

| Energy Use | Can be less efficient due to water heating | Generally more energy-efficient |

| Maintenance | Requires regular water changes and de-liming | Simpler to clean; requires checking heating elements |

| Risk | Can make crispy foods soggy | Can dry out delicate foods if not managed |

Ultimately, many kitchens find they need both. A combination approach lets you hold every single menu item in its ideal environment, ensuring peak quality from the first serving to the last.

Formats, Finishes, and Features

Beyond how it heats, the actual design of the counter matters a lot. For a busy food truck on the Strip, a compact countertop unit is a must. These smaller models can team up perfectly with other gear like a countertop commercial convection oven to create a powerful, space-saving station. But if you're outfitting a massive casino buffet, you'll need a full-size floor model with a ton of wells to handle the sheer volume and variety.

The material and finish are also key. Stainless steel is the industry standard for a reason—it's tough, a breeze to sanitize, and gives off a clean, professional vibe. Don't overlook the small details, either. Features like built-in LED lighting can make a huge difference in presentation, making your food look more vibrant and tempting, which can seriously influence what customers choose and ultimately boost your sales.

Planning Your Hot Food Counter Size and Capacity

Picking the right size for your hot food counter is about more than just finding an empty spot on your floor. It’s a make-or-break decision that hits your service speed, food quality, and customer happiness—especially during those crazy peak hours that are just another day in the Las Vegas dining scene.

Think of it like designing a freeway on-ramp. Too small, and you've got instant gridlock. Too big, and you're just wasting prime real estate and burning through cash on energy bills. The sweet spot is a seamless flow from your kitchen to the customer, with zero bottlenecks.

Getting this right means taking a hard look at your menu, your customer traffic patterns, and how your kitchen actually operates. The needs of a massive buffet on the Strip feeding thousands are worlds apart from a cozy, quick-service spot in Henderson. A huge operation might need a 10-well floor model to show off the menu, but a smaller joint could get by just fine with a compact three-well countertop unit.

Figuring Out Your Peak Demand

First things first: plan for the chaos. Don't base your needs on a slow Tuesday lunch; you need to build for that slammed Saturday night dinner rush. Ask yourself: how many hot items are we serving at once? And how fast are we burning through them? The answers tell you exactly how many wells you'll need.

A classic rookie mistake is underestimating the menu. If you've got eight hot mains and six sides, you need a unit that can handle all of it. Pan sizes are a huge part of this puzzle, too. Your counter has to work with standard hotel pans.

- Full-Size Pans: These are your workhorses for high-volume stuff like fried chicken or mac and cheese.

- Half-Size Pans: Great for splitting a well between two different items, like putting roasted veggies next to mashed potatoes.

- Third-Size Pans: Maximum flexibility. Perfect for smaller portions of sauces, gravies, or specialty toppings.

Just imagine: a single four-well counter can hold four full-size pans, eight half-size pans, or even twelve third-size pans. That’s some serious versatility if you plan it out.

Making Sure Capacity and Kitchen Flow Work Together

Your hot food counter isn't an island; it's a critical link in your kitchen's chain of command. The path from raw ingredient to finished plate has to be a smooth, uninterrupted flow. And that journey starts with your cold storage.

Top-notch commercial refrigerators are ground zero, keeping prepped ingredients fresh and safe before they even see a flame. Likewise, reliable commercial freezers help you manage your inventory so you’re always ready for an unexpected rush. The speed of your hot-holding station is tied directly to how fast your crew can pull from cold storage, cook, and get food back on the line.

And let's not forget where we are. In the Las Vegas heat, supporting gear like ice machines is non-negotiable for the customer experience. A solid ice machine ensures your beverage station—often right next to the service line—keeps up with demand, rounding out the meal perfectly.

A smart service line is a whole ecosystem. You want to shrink the distance from the walk-in, to the cookline, to the hot food counter. Every second saved during a rush is pure gold.

When you map out this entire workflow, you can place your hot counter in the perfect spot to optimize movement and cut down on physical strain. This way, your investment doesn't just hold food at the right temp; it makes your whole Las Vegas restaurant run smoother, keeping your staff sane and your customers coming back.

Maintaining Food Safety and Temperature Control

In a city like Las Vegas, where a restaurant's reputation can be made or broken overnight, food safety isn't just a rule—it's everything. Your hot food counter is more than a shiny piece of equipment; it's the front line in the never-ending battle to keep your customers safe and your food delicious.

Getting temperature control right is an absolute non-negotiable. It’s a promise to every single guest that you take their well-being seriously.

This focus on safety and quality is a huge reason the global market for hot food serving counters was valued at a whopping USD 2.5 billion in 2023. It’s expected to nearly double to USD 4.5 billion by 2032. This isn't surprising when you consider that quick-service spots make up a massive 42% of the food service industry.

Understanding NSF and ETL Certifications

When you're shopping for equipment, you'll see two acronyms everywhere: NSF and ETL. These aren't just fancy stickers. They're your proof that the equipment meets strict public health and safety standards—a must-have for any commercial kitchen in Clark County.

Think of them as a seal of approval. They confirm the unit is built from food-safe materials, is a breeze to clean, and won’t become a breeding ground for bacteria.

- NSF (National Sanitation Foundation): This one is all about public health. An NSF-certified unit is designed without hard-to-clean nooks and crannies where germs love to hide. It's built from materials that won't corrode or leach into your food.

- ETL (Intertek Testing Services): This certification focuses on electrical safety. An ETL mark means the unit has been tested to make sure it won't be a fire or shock hazard, which is critical for equipment that's on for hours at a time.

With how tough health inspections are here in Vegas, having both NSF and ETL certifications is your ticket to passing with flying colors.

Avoiding the Temperature Danger Zone

The number one job of your hot food counter is to keep hot food hot. The "temperature danger zone" is that dreaded range between 40°F (4°C) and 140°F (60°C). It's where nasty bacteria like Salmonella and E. coli throw a party and multiply like crazy.

Food safety 101: Hot food must be held at 140°F (60°C) or higher. Period. Letting the temperature dip below that, even for a few minutes, is asking for trouble.

This is where the quality of your equipment really shines. A reliable hot food counter with a precise digital thermostat lets your team set and monitor temperatures without guessing. Even better are the units with individual controls for each well, giving you the power to hold different dishes at their perfect serving temperatures.

Make it a house rule: check temperatures constantly with a food thermometer. This ensures every single dish stays safely above that 140°F mark.

The Role of Supporting Equipment

Your hot-holding game is only as strong as its weakest link. Your hot food counter needs a solid supporting cast of cold storage to create a safe, seamless workflow from the walk-in to the customer's plate. Success in Las Vegas requires essential restaurant equipment working in harmony.

- Commercial Refrigerators: This is where food safety begins. They keep your ingredients out of the danger zone before they're cooked, ensuring everything hitting the line is fresh.

- Commercial Freezers: These are your inventory workhorses. They let you safely store products long-term, so you're always ready for those unpredictable Vegas rushes.

- Ice Machines: Out here in the desert, a dependable ice machine is non-negotiable for keeping drinks cold and customers happy.

Don't forget that the efficiency of these units plays a huge role in your monthly power bill. For a closer look at that, check out our guide on selecting energy-efficient commercial refrigeration.

By pairing a top-notch hot food counter with reliable refrigerators and freezers, you're not just buying equipment—you're building a complete system designed for safety, quality, and peak performance.

Building a Smooth Kitchen Workflow

Your hot food counter might be the star of the show, but it can't perform solo. It’s a key player in a much bigger kitchen ecosystem where every single piece of equipment has to work together seamlessly. In the fast-paced, high-stakes food scene of Las Vegas, a smooth workflow isn't just a nice-to-have—it's essential for survival.

Think of it as a production line. The whole system is built on a logical flow: from cold storage to prep, onto the cookline, and finally to the customer-facing service line. If there's a hiccup anywhere in that chain, it can cause delays, tank your food quality, and leave you with frustrated staff and angry customers. The trick is to design a kitchen layout where each step flows right into the next, cutting out wasted motion and cranking up your output.

The Hot and Cold Connection

Every dish that lands on your hot food counter starts its journey long before it gets there. It all begins in cold storage. High-quality commercial refrigerators are the unsung heroes here, acting as your first line of defense for food safety and quality. They hold all your prepped ingredients—from fresh-cut veggies to marinated meats—at precise, safe temperatures, ready to hit the cookline at a moment's notice.

And let's not forget commercial freezers. They are absolutely crucial for managing your inventory, especially when dealing with the wild swings in customer traffic that are just another Tuesday in Las Vegas. Freezers let you stock up on essential ingredients, so you don't have to sweat running out of a bestseller during the dinner rush.

A well-oiled cold line is the secret to a high-speed hot line. Being able to grab ingredients from a commercial refrigerator or freezer and get them straight to the cooking station is what keeps the whole machine running. Without that synergy, even the best hot food counter will constantly be waiting for a restock.

Laying Out an Ergonomic Service Area

Ergonomics makes a huge difference in kitchen speed. A clunky layout forces your crew to take extra steps, reach for things awkwardly, or constantly bump into each other. That leads to burnout and slows everything down. A well-designed kitchen, on the other hand, just feels right, creating a direct path for every single task.

The best workflows follow a straight or U-shaped line:

- Storage: Ingredients come out of the commercial refrigerators and freezers.

- Prep: Items get washed, chopped, and prepped at dedicated tables.

- Cooking: Food hits the ranges, griddles, or fryers.

- Holding: Finished dishes are moved to the hot food counter to be served.

This kind of linear setup means no one is backtracking or getting in anyone else's way. It's all about creating a rhythm where every movement has a purpose, which cuts down on physical strain and shaves precious seconds off every order.

Don't Forget the Rest of the Experience

In the middle of the scorching Las Vegas heat, a great meal needs a perfectly cold drink to go with it. That’s where commercial ice machines become non-negotiable. Sticking an ice machine right near your beverage station—which is usually next to the service line—really completes the customer experience. You'll have a constant supply of fresh ice for sodas, iced tea, and water, perfectly complementing the hot food from your counter.

This isn't just about quenching thirst. It streamlines another vital part of the service, preventing a bottleneck at the drink station and letting your staff pull together an entire order in one smooth trip. By pairing your hot food counter with dependable refrigerators, freezers, and ice machines, you build a powerful, cohesive system. That's exactly how the most successful restaurants in Las Vegas conquer the chaos of peak hours, delivering amazing quality and speed, night after night.

Installation and Maintenance in Las Vegas

Getting the right hot food counter for your Las Vegas spot is a great first step, but it's only half the battle. Making sure it’s installed correctly and maintained with care is what really protects your investment. This is what keeps it running perfectly through the busiest dinner rush and keeps your kitchen safe and up to code.

Think of installation as laying the groundwork for a killer service line. It’s way more than just plugging it in—it's about a smart plan that accounts for the realities of working in our desert climate.

Getting the Setup Right from Day One

A proper install is everything for safety and efficiency. Here in Las Vegas, managing ambient heat is always on our minds, so ventilation has to be a top priority. A unit that isn't breathing properly can crank up the temperature in your kitchen, stressing out your staff and putting a heavy load on your other gear, like your walk-in coolers and ice machines.

Before that new hot food counter even hits your loading dock, get these details sorted:

- Electrical Requirements: Double-check that you have the right voltage and, just as importantly, dedicated circuits. Overloading a circuit is a serious fire risk and a surefire way to cause an expensive shutdown.

- Proper Ventilation: Your unit absolutely needs to sit under a capable ventilation hood. This setup will pull out all that extra heat and steam, keeping your kitchen air clear and your team comfortable.

- Level and Stable Placement: Make sure the floor where it's going is perfectly level. An uneven counter won’t just heat food inconsistently; it can create spill hazards that put your staff at risk.

Skipping these steps is like trying to build a house on a shaky foundation. You’ll just be creating headaches for your future self. Take the time to get it right from the start, and your hot food counter will work exactly as it should from day one.

A Practical Maintenance Checklist for Las Vegas Kitchens

Want your equipment to have a long, trouble-free life? The secret is consistent, preventative maintenance. A few simple checks folded into your daily routine can save you a fortune in emergency repair bills and lost business. This focus on upkeep is crucial, as the broader food service industry is projected to grow from USD 3.9 trillion in 2025 to USD 6.5 trillion by 2035, with efficiency being a major driver of success.

A solid maintenance plan isn't complicated. It just needs to be consistent.

- Daily Cleaning: Wipe down every surface, from the sneeze guards to the control knobs. This is non-negotiable for sanitation.

- Weekly Checks: Take a close look at the heating elements for any signs of damage or wear. If you have a steam table, drain and clean the water pans to stop mineral scale from building up.

- Monthly Thermostat Calibration: Grab a reliable thermometer and check if your thermostat is accurate. This ensures your food is always held at a safe, compliant temperature.

If you run into a problem that's more than a simple fix, you need a trusted local tech you can call. And for issues that go beyond your hot line, like a struggling walk-in cooler, our guide on commercial refrigeration repair in Las Vegas can point you in the right direction. Having reliable help on standby means you can tackle any problem fast and keep your kitchen humming.

Your Questions Answered: Hot Food Counters

Here are some of the most common questions we get from operators here in Vegas.

What Kind of Sneeze Guard is Best for My Las Vegas Restaurant?

It really comes down to your service style. If you run a full-service counter where your staff plates everything for the customer, a simple, straight vertical glass barrier gets the job done.

But for the self-service buffets so common in Las Vegas resorts, you'll need more coverage. Think angled or curved guards that wrap over the food—they're absolutely essential for keeping everything safe and compliant with health codes.

What Power and Space Do I Need?

First thing's first: check your electrical setup before you buy. Most commercial hot food counter units are serious pieces of equipment and need a dedicated 208V or 240V circuit. Don't guess on this one.

You also need to measure your service line like a hawk. Make sure you leave at least 36 inches of clear aisle space. In a busy Las Vegas dining room, that space is critical for keeping staff and guests moving smoothly without creating a bottleneck.

What is the Best Way to Clean My Hot Food Counter?

Daily cleaning isn't optional—it's a must. Grab a food-safe, non-abrasive cleaner and a soft cloth to wipe down every stainless steel surface, all the controls, and the sneeze guards.

If you have a steam table, drain the water every single day. This prevents mineral buildup, which is a major headache with the notoriously hard water we have here in Las Vegas.

One of the biggest mistakes we see is people using harsh chemicals like bleach. It seems like a good idea, but it can wreck the stainless steel finish over time. Always stick to approved sanitizers to protect your investment and stay on the right side of the health inspector.

How Do I Integrate a Hot Food Counter with My Other Equipment?

A smart kitchen layout is all about creating a seamless workflow. Think of your hot food counter as the final stop, positioned right after your main cookline.

It should also be logically placed near your cold storage. Having your commercial refrigerators and commercial freezers close by makes restocking a fast, easy job instead of a long trek across the kitchen. And if you can place it near your ice machines and drink stations, you’ll streamline the entire ordering process for everyone.

Ready to build a reliable and efficient service line for your Las Vegas establishment? Explore our full range of professional-grade kitchen solutions at Las Vegas Restaurant Equipment and get the gear you need delivered fast. Visit us at https://lasvegasrestaurantequipment.com.