Opening a restaurant in the high-stakes world of Las Vegas demands a rock-solid operational foundation. It all starts with a meticulous commercial kitchen equipment checklist.

This guide is your starting point, specifically built for the unique pressures of operating in Nevada. We'll cover everything from your walk-in coolers to the cooking line, because outfitting your kitchen correctly from day one is your ticket to efficiency and long-term profit.

Building Your Kitchen Foundation for Las Vegas Success

From the glittering Strip to the booming neighborhoods in Summerlin and Henderson, the vibrant city of Las Vegas is home to a diverse array of restaurants that cater to every palate. To make it here, you have to be ready for anything. That prep work begins long before your first guest arrives—it starts in the back-of-house with a solid equipment plan.

Every single successful restaurant, whether it's a massive casino buffet or a cozy local bistro, runs on a core set of essential restaurant equipment. Your entire operation, and your ability to serve quality food consistently, depends on the reliability of these tools. This isn't just about buying appliances; it’s about investing in the very engine of your business.

Core Equipment Categories

At the heart of any kitchen are three fundamental areas that need your full attention right away: refrigeration, cooking, and preparation. These are the pillars supporting every single dish that goes out to your dining room.

-

Commercial Refrigerators: These are the workhorses keeping your ingredients fresh in the desert heat. From huge walk-in coolers for bulk storage down to the smaller undercounter units on the line, getting your refrigeration right is non-negotiable for success.

-

Commercial Freezers: Absolutely essential for preserving pricey proteins and pre-made items. The right commercial freezers help you manage inventory like a pro and cut down on food waste.

-

Ice Machines: In Vegas, ice isn't a luxury—it's a core utility for every bar, restaurant, and hotel. You need a reliable, high-capacity ice machine that can keep up with 24/7 demand.

It’s hard to overstate how critical this initial setup is. Just imagine a casino hotel's food-and-beverage team scrambling because their ice machines can't keep up. It's a disaster.

The market size reflects this reality. According to Grand View Research, the commercial kitchen appliance market was valued at USD 98.34 billion in 2024 and is expected to hit USD 149.34 billion by 2030. This growth is fueled by restaurants modernizing their kitchens and new spots opening up constantly.

A well-thought-out equipment list does more than just fill your space. It dictates your kitchen's workflow, impacts your energy bills, and ensures you meet the strict standards of the Southern Nevada Health District.

Before you buy a single piece of equipment, you have to map out your kitchen's flow. Proper planning right now will save you from incredibly expensive mistakes down the road and guarantee your kitchen runs smoothly from the start.

To get a head start, check out our guide on designing a restaurant kitchen for an efficient layout. Believe me, the time you invest in planning now will pay you back for years to come.

Essential Equipment Checklist by Kitchen Station

To give you a clearer picture, we've broken down the must-have equipment by station. Think of this table as your starting point—a high-level overview of the essentials every functional kitchen area needs.

| Kitchen Station | Essential Refrigeration | Essential Cooking Equipment | Essential Prep & Storage |

|---|---|---|---|

| Receiving & Storage | Walk-In Cooler, Walk-In Freezer | - | Dunnage Racks, Shelving Units, Scales |

| Food Preparation | Undercounter/Worktop Refrigerator, Prep Table Refrigerator | - | Prep Tables, Food Processors, Mixers, Slicers, Sinks |

| Cooking Line (Hot Line) | Lowboy/Chef Base Refrigerator | Range, Griddle, Fryer, Charbroiler, Convection Oven | Stainless Steel Tables, Heat Lamps, Hood/Ventilation System |

| Bakery/Pastry | Reach-In Refrigerator/Freezer, Dough Retarder | Deck Oven, Convection Oven, Proofer | Dough Sheeter, Planetary Mixer, Work Tables, Baker's Racks |

| Warewashing | - | - | 3-Compartment Sink, Commercial Dishwasher, Dishtables |

This list covers the big-ticket items that form the backbone of your operation. As you refine your concept and menu, you’ll add more specialized pieces, but this core setup is where every successful Las Vegas kitchen begins.

Mastering Cold Storage in the Desert Heat

Let's be blunt: in Las Vegas, your cold storage isn't just another line item on a checklist. When summer temperatures climb past 110°F, your refrigeration is the lifeline protecting your entire inventory and, frankly, your reputation. A struggling walk-in or a dying ice machine can bring a packed service on the Strip to a screeching halt.

This is why the refrigeration section of your commercial kitchen equipment checklist needs your full attention.

The absolute most critical factor for any cold storage unit in Nevada is its high-ambient temperature rating. This spec tells you the maximum outside temperature the unit can handle before it stops working efficiently. Standard units are often rated for a comfortable 85°F, but we both know a Las Vegas kitchen during a summer rush gets way hotter than that.

If you pick a unit not built for our desert climate, its compressor will be forced to run non-stop. This leads to two things no one wants: a premature breakdown and an astronomical NV Energy bill. You have to look for units rated to perform in at least 90°F to 100°F environments. It's the only way to ensure your food stays safe and your equipment doesn't burn itself out.

Choosing The Right Capacity And Type

Your specific menu and customer volume will point you to the right mix of cold storage. A high-end steakhouse needs a massive walk-in freezer for its prime cuts, but a quick-service cafe might just need a few solid reach-in refrigerators.

- Walk-In Coolers and Freezers: These are for your bulk inventory—produce, dairy, proteins. Always plan for enough space inside to let air circulate properly around your boxes and bins.

- Reach-In Refrigerators and Freezers: Think of these as the workhorses on the line. They give your cooks immediate access to prepped ingredients right in the heat of service.

- Undercounter and Bar Coolers: Invaluable for squeezing storage into tight spaces. Perfect for a nightclub bar or a cramped prep station, they keep crucial items right at your staff's fingertips.

- Ice Machines: A non-negotiable in Las Vegas. The choice comes down to how much you need and what kind of ice you want—cubed for drinks, flaked for seafood displays. My advice? Always size up to handle the busiest summer weekend.

A rookie mistake I see all the time is underestimating cold storage needs. It is always better to have a little more capacity than you think you need. It prevents staff from over-stocking units, which blocks airflow and creates dangerous temperature swings.

Compliance and Efficiency Considerations

When you're shopping for equipment, there are two acronyms you can't ignore: NSF and ETL. These marks mean the equipment meets strict public health and safety standards. The Southern Nevada Health District inspector will be looking for those stickers, so making sure your units are compliant is a must-do.

Beyond just passing inspection, energy efficiency is a huge deal for your bottom line. Keep an eye out for ENERGY STAR® certified models, which can be 15-30% more efficient than their standard counterparts. That initial investment in efficiency pays you back every month on your power bill.

To really dig into how these choices affect your finances, check out our guide on selecting energy-efficient commercial refrigeration. It breaks down exactly how the right unit can save you serious money.

Equipping Your Cooking and Prep Stations

This is it—the heart of your kitchen. The cooking and prep stations are where your menu truly comes alive, so this section of your commercial kitchen equipment checklist needs to be spot-on. It doesn't matter if you're slinging tacos from a high-volume food truck in Henderson or crafting tasting menus on the Strip; getting this gear right is non-negotiable for a smooth service.

The demand for quality cooking equipment is absolutely booming. According to Future Market Insights, the global market is expected to jump from USD 13.3 billion in 2025 to a staggering USD 26.5 billion by 2035. That tells you everything you need to know—restaurants everywhere are investing in reliable, efficient equipment to handle the pressure.

The Great Debate: Gas Versus Electric

Here in Nevada, the choice between gas and electric is more than just a chef's preference. It's a strategic move that hits your performance, your utility bills, and your kitchen's workflow.

-

Gas Equipment: Most chefs I know swear by gas ranges and charbroilers. You get that instant, raw power and precise temperature control that's perfect for searing a steak or working a busy sauté station. The trade-off? You’ll need a proper gas line hookup, and it throws off more ambient heat, which can make a Las Vegas kitchen even hotter.

-

Electric Equipment: On the other side, you have electric gear like convection ovens and induction cooktops. These are champions of even, consistent heat. Think perfect pastries and delicate sauces. They're also generally more energy-efficient and a breeze to clean, which adds up to real savings over time.

Honestly, the smartest kitchens in town run a hybrid setup. You might see a beast of a gas charbroiler for that signature grilled flavor sitting right next to an electric convection oven for all the baking. It’s all about using the right tool for the job.

No matter what you choose, don't even think about cutting corners on your ventilation system. The Southern Nevada Health District has very strict codes for kitchen hoods, and for good reason—air quality and fire safety. Skimping here is a massive mistake.

Essential Gear for the Hot Line

Your main cooking line, often called the "battery," is where the magic happens. Every piece of equipment here needs to be a total workhorse, built to withstand the punishing pace of a dinner rush.

Your checklist for the hot line absolutely has to include:

- Commercial Range: The classic centerpiece. You can find them with all sorts of combinations—open burners, griddles, ovens, you name it.

- Fryers: Critical for everything from French fries to calamari. I always recommend looking at high-efficiency models to cut down on your oil costs.

- Charbroiler/Grill: You can't beat that smoky flavor for meats, fish, and vegetables.

- Griddle/Flat-Top: A true multi-tasker. Perfect for breakfast service, smashing burgers, or getting a perfect sear on scallops.

- Convection Oven: A must-have. The internal fans circulate hot air, which means faster, more even cooking and baking. If space is tight, check out our guide to see if a countertop commercial convection oven could work for you.

Don't forget the prep tables. For fast-casual spots or busy casino floor eateries, specialized sandwich and pizza prep tables with built-in refrigerated wells are lifesavers. They keep your ingredients chilled and right where you need them, which radically speeds up assembly and keeps the health inspector happy. To keep everything in peak condition, it's also smart to stock up on the right maintenance products for advanced cooking equipment.

Warewashing, Storage, and Safety Essentials

A sparkling clean cooking line is fantastic, but it means absolutely nothing if the plates coming out are grimy. This is where the unsung heroes of your Las Vegas kitchen come in: the warewashing, storage, and safety gear. This isn't the flashy part of your commercial kitchen equipment checklist, but it's the bedrock of a successful operation that keeps you in good standing with the health department.

Great food might be the star of the show, but impeccable hygiene is the stage it's performed on. This part of your kitchen is where you shut down cross-contamination and hold the line on the high standards that both your customers and the Southern Nevada Health District inspectors demand. Believe me, cutting corners here is never an option.

Warewashing Workhorses

When you're in the middle of a dinner rush, your dish pit has to be a ruthlessly efficient machine. The heart of it all is your commercial dishwasher, and you've basically got two roads you can go down:

- High-Temp Dishwashers: These powerhouses use a booster heater to get the rinse water screaming hot, up to 180°F, to sanitize everything. The upside is they clean and flash-dry dishes incredibly fast without needing extra chemical sanitizers.

- Low-Temp Dishwashers: These units run at cooler temperatures, typically between 120-140°F, and rely on chemical sanitizers to do the heavy lifting. They often use less energy, but you'll have an ongoing expense for the chemicals.

No matter which machine you choose, a three-compartment sink is absolutely non-negotiable. You will not pass a health inspection without one. It's your go-to for the classic wash, rinse, and sanitize process and serves as a crucial manual backup. Plus, it’s the only place you'll be able to tackle those giant stockpots and pans that would never fit in a dishwasher.

Smart Storage and Organization

I've seen it a thousand times: an organized kitchen is a fast kitchen. When everything has a home, you reduce clutter, minimize the risk of accidents, and make tracking inventory a whole lot less painful.

Your basic storage setup should include:

- Stainless Steel Work Tables: You need these durable, easy-to-sanitize surfaces everywhere for prep.

- Shelving Units: Go vertical to make the most of your space for dry goods, pots, pans, and smaller appliances.

- Dunnage Racks: These are essential for keeping heavy items like 50-pound bags of flour or bulk boxes of oil safely off the floor. This isn't just a good idea; it's a major health code rule.

Think of your storage layout as a strategic map for efficiency. Grouping items by station—spices near the range, plates near the pass—saves precious seconds during service, which adds up to a smoother operation.

Mandating a Safe Environment

Let's be clear: your safety equipment is the single most critical investment you will make. A safe kitchen protects your people, your building, and the future of your entire business.

At the top of your list is a professionally installed fire suppression system (like the industry-standard Ansul systems) that covers all your cooking equipment. Beyond that, place high-quality non-slip floor mats in every high-traffic and potentially slick area, especially the dish pit and the cook line. These aren't just helpful suggestions; they are the fundamental requirements for running a responsible and compliant kitchen.

Navigating Equipment Procurement and Logistics

Alright, you've got your finalized checklist. Now the real fun begins. Getting that shiny new gear from a supplier's warehouse to your kitchen in Las Vegas requires a solid game plan, especially with your grand opening date looming. This isn't just about placing an order; it's a whole dance of procurement, shipping, and installation that needs to be perfectly timed.

For those of us operating here in Nevada, it pays to work with a supplier who gets the local scene. I always look for providers who offer showroom-free pricing—it cuts their overhead, and those savings get passed straight to you. Another must-have is fast freight shipping. Trust me, getting a replacement freezer delivered in one or two business days can be the difference between a small headache and a full-blown crisis.

The Procurement Timeline

Mapping out your timeline is absolutely critical if you want to avoid expensive delays. Don't leave this to the last minute. You should be thinking about this weeks, if not months, before you even dream of opening your doors.

Here’s a rough guide I stick to:

- Initial Quotes (6-8 weeks out): This is when you start ringing up suppliers and getting quotes. It gives you enough breathing room to compare prices, check who has what in stock, and get a feel for the lead times on specific pieces from your commercial kitchen equipment checklist.

- Finalizing the Order (4-6 weeks out): Time to pull the trigger. Get those orders placed, especially for anything custom or big-ticket items like walk-in coolers. Those can have some seriously long manufacturing lead times you need to account for.

- Coordinating Delivery (1-2 weeks out): Schedule your deliveries for when the site is actually ready and secure. The last thing you want is $50,000 worth of equipment sitting on a sidewalk or in the middle of an unsecured construction zone.

Sticking to a schedule like this helps ensure every piece shows up when you need it, preventing a logistical nightmare that could derail your opening. If you want to dive deeper into the nitty-gritty of the whole process, it's worth understanding effective logistics management.

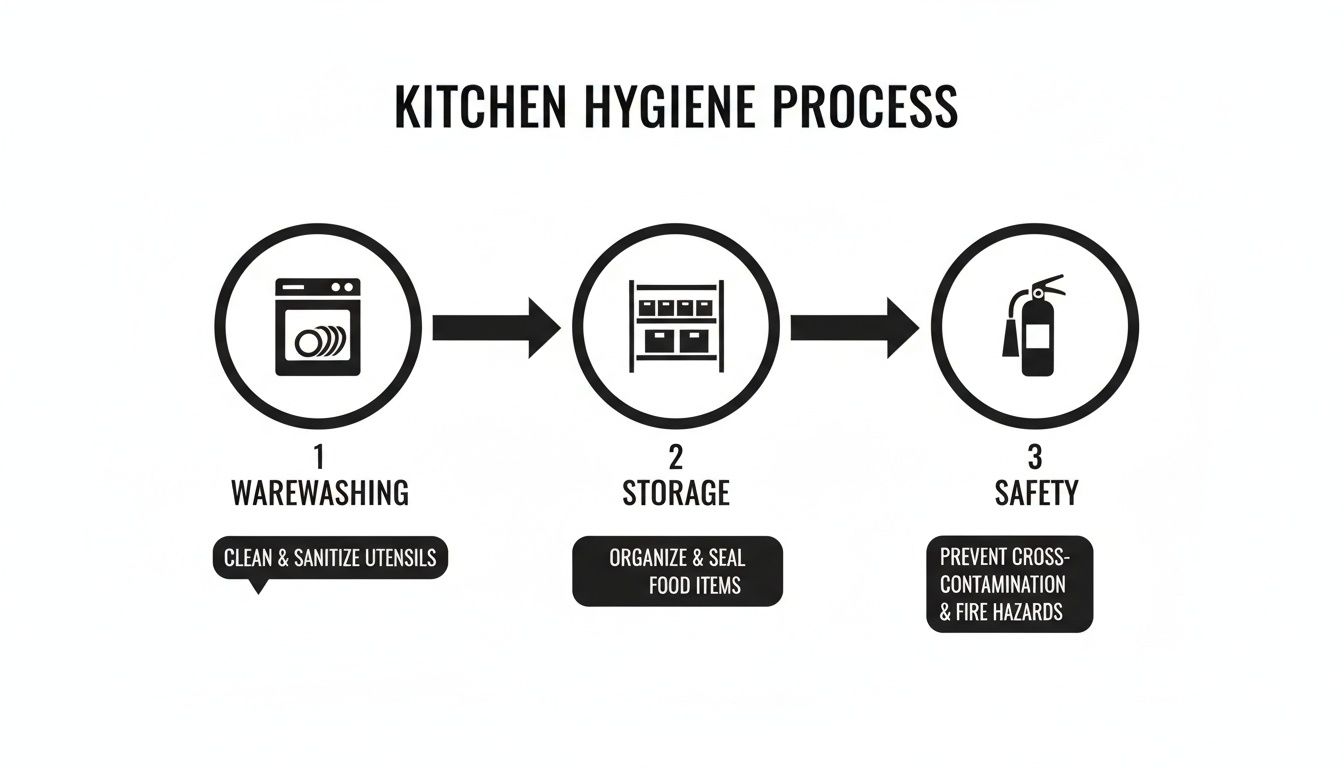

Once all that equipment is in place, your focus immediately shifts to hygiene and safety.

This flow really drives home how crucial proper warewashing, organized storage, and solid safety protocols are for running a tight, compliant kitchen from day one.

Demystifying Financing and Final Steps

For any new restaurant or one looking to expand, cash flow is king. This is where financing programs can be a real lifesaver, letting you get the high-quality, essential gear you need without draining your capital all at once. Most of these programs offer flexible terms that are built for the unique ups and downs of the restaurant business.

Whether you’re a bar operator off the Strip or a grocery buyer out in Enterprise, that detailed commercial kitchen equipment checklist is your key to profitability. And the demand is only growing; market forecasts from Technavio project the global market to jump by USD 41.81 billion between 2024 and 2029, with core items like ranges and fryers leading the charge.

Your final step is commissioning. This is non-negotiable. It means uncrating, installing, and testing every single piece of equipment. Always, and I mean always, have a professional handle the final hookups for gas, plumbing, and electrical. It ensures everything is safe, up to code, and ready for that first dinner rush.

Questions We Hear All the Time About Las Vegas Kitchen Equipment

Stepping into the world of commercial kitchen equipment can feel like a lot, especially in a city as fast-paced as Las Vegas. We get it. From high-volume kitchens on the Strip to cozy spots in Henderson, operators run into the same handful of questions when it comes time to invest in their gear. Getting these answers straight from the beginning will save you a world of headaches and help you build a smarter commercial kitchen equipment checklist.

One of the biggest concerns we hear? How to choose equipment that won't die in the Nevada heat. It's a legitimate worry. Your standard-issue commercial refrigerator or ice machine is going to fight a losing battle when summer temps are cooking. This leads to breakdowns, emergency service calls, and lost product. The fix is to look for units built for high-ambient temperatures—they’re specifically engineered to keep their cool when your kitchen heats up.

Another classic dilemma is whether to patch up that old, failing piece of equipment or just replace it. A quick repair might look good on paper, but it's usually just kicking the can down the road.

Here's a solid rule of thumb we've seen hold true for years: If a repair is going to cost you more than 20% of what a new, comparable unit would, it’s time to replace it. Throwing good money after bad on an old machine is a trap that bleeds your budget dry.

Are You Set Up for the Right Power and Utilities?

This is a huge one, and it trips up more new restaurant owners than you’d think. You can have the shiniest new equipment, but if you can’t plug it in or hook it up, it’s just a very expensive paperweight.

- Gas vs. Electric: Do you actually have the right gas lines and pressure for that beast of a six-burner range? Is your electrical panel beefy enough to handle a high-powered convection oven and a walk-in freezer without blowing a fuse?

- Water and Drainage: Your new ice machine and high-temp dishwasher need specific water lines and drains. It’s absolutely critical to get your contractor to confirm you have the right hookups before that delivery truck shows up.

Make it a habit to check the spec sheet for every single item on your list. Match it against your building's infrastructure. Trust me, a last-minute emergency call to a plumber is a painful and completely avoidable expense.

How Long Will This Stuff Actually Last?

Knowing the general lifespan of your equipment is key for long-term budgeting. Not everything is built to last forever, even if you take great care of it.

| Equipment Category | Typical Lifespan |

|---|---|

| Refrigeration Units | 10-15 years |

| Cooking Equipment | 8-12 years |

| Dishwashers & Ice Machines | 5-10 years |

The absolute best way to hit—or even exceed—these numbers is with consistent, preventative maintenance. We’re not talking about major overhauls. Simple things like cleaning filters and checking door seals on your commercial refrigerators and freezers can add years to their life. A little planning upfront ensures your kitchen is built to last.

Ready to build a kitchen that can handle the heat? At Las Vegas Restaurant Equipment, we hand-pick high-performance, warranty-backed equipment that’s perfect for the Nevada climate. From rugged Atosa commercial refrigerators and ice machines to full cooking lines, we offer showroom-free pricing and fast, free shipping right here in the Las Vegas area. Get the gear you need to succeed by visiting us at https://lasvegasrestaurantequipment.com.