A commercial Italian ice machine isn't just another freezer. It's a very specific piece of equipment, built from the ground up to churn out huge batches of that smooth, refreshing, dairy-free frozen dessert we all love. It’s completely different from an ice cream or sorbet machine; this one is engineered to get that perfect water-based, crystalline texture that makes Italian ice authentic.

Frankly, it's an investment that unlocks a seriously high-margin product, which is a lifesaver in hot climates like ours.

Why Italian Ice Is a Smart Bet for Las Vegas Businesses

In the vibrant, competitive food scene here in Las Vegas, a diverse array of restaurants caters to every palate, from tourists wandering the Strip to locals grabbing a bite in Henderson. To really stand out, you have to offer something different. Everyone is always looking for something new and refreshing.

This is where a commercial Italian ice machine stops being just a piece of equipment and starts becoming a real strategic advantage.

Let's be honest, the desert heat makes cold treats a year-round necessity, not just a summer thing. While tons of places have the standard ice cream or froyo, Italian ice gives you a powerful way to be different. It's light, packed with intense flavor, and—this is a big one—it's dairy-free. That alone opens you up to a much wider group of customers, especially those with dietary restrictions.

The Profitability of Frozen Desserts

Every food business runs on essential restaurant equipment needed for success: commercial refrigerators, commercial freezers, and ice machines. They're the backbone of any kitchen. A commercial Italian ice machine slides right into that setup, adding a high-profit menu item with surprisingly low ingredient costs. The markup on a single cup of Italian ice can be huge, making it a fast track to boosting your revenue, especially when the tourists are in town.

Think about all the different places it could work across the valley:

- Strip Casinos and Hotels: Imagine a grab-and-go treat by the pool or a quick, refreshing dessert in a bustling food court. It’s a perfect fit.

- Summerlin Cafes: This is an ideal afternoon snack for families and a great dairy-free alternative to the usual gelato spots.

- Downtown Food Trucks: A simple, high-demand product that requires almost no prep and lets you serve customers lightning-fast.

A key to success in the Las Vegas market isn't just about having great food. It's about having reliable equipment that can produce it consistently, day in and day out. A solid Italian ice machine means you can meet demand without unexpected downtime, which protects both your reputation and your bottom line.

Ultimately, choosing the right NSF/ETL compliant machine is crucial for staying on the right side of local health codes. It pays to partner with a local supplier who gets the demands of the Las Vegas climate and can offer quick support when you need it. And if you're really looking to expand your frozen menu, you might even consider exploring options like commercial frozen beverage dispensers to diversify your offerings even more.

How a Commercial Italian Ice Machine Really Works

To get what makes perfect Italian ice, you have to look under the hood. A commercial Italian ice machine isn't just a freezer—think of it more like a high-performance engine. It's a system where every part has a specific job, all working together to churn out that smooth, crystalline texture that makes Italian ice so good.

For a busy spot in Las Vegas, where you need consistency and can't afford downtime, understanding how these machines work is crucial. Your kitchen already depends on workhorses like commercial refrigerators and commercial freezers. An Italian ice machine is another one of those essential pieces, but its mechanics are what will separate your premium product from something that’s just a sad, icy mess.

The Heartbeat of the Machine

The real action happens inside the freezing cylinder. This is where your liquid base—a simple blend of water, sugar, and flavor—goes from liquid to dessert. It's the heart of the whole operation, a chamber that has to hit and hold a very precise temperature, usually just below freezing.

But if you just froze the mix, you'd get a block of flavored ice. That’s where the machine’s muscle comes in. Inside that cylinder, a rotating blade called a dasher (or auger) is constantly scraping the walls. This does two critical things: it keeps large ice crystals from forming and it folds in a tiny, controlled amount of air. This process is what guarantees a smooth, scoopable final product, not a hard, chunky one.

That constant motion from the dasher is the secret to Italian ice's signature dense-yet-soft texture.

The Powerhouse Behind the Chill

Driving the whole cooling process is the compressor. You can think of it as the machine's lungs. It circulates refrigerant through a system of coils, pulling heat out of the freezing cylinder and pushing it out into the air. This constant heat exchange is what lets the machine flash-freeze the mix.

In a slammed Las Vegas kitchen, the quality of your compressor is everything. A heavy-duty compressor gives the machine a fast "recovery time," meaning it can freeze a new batch almost immediately after you’ve emptied it. That's a lifesaver when you've got a line out the door on a hot summer day.

The global demand for solid cooling equipment proves how important this is. The commercial ice machine market is exploding, especially in high-volume places like Vegas casinos and bars. In 2025, the market is sitting at a cool USD 2.1 billion and is expected to hit USD 4.5 billion by 2035, growing at a steady CAGR of 7.80%. That kind of growth is what keeps restaurant owners investing in better gear. You can dig into the numbers in the full commercial ice machine market report.

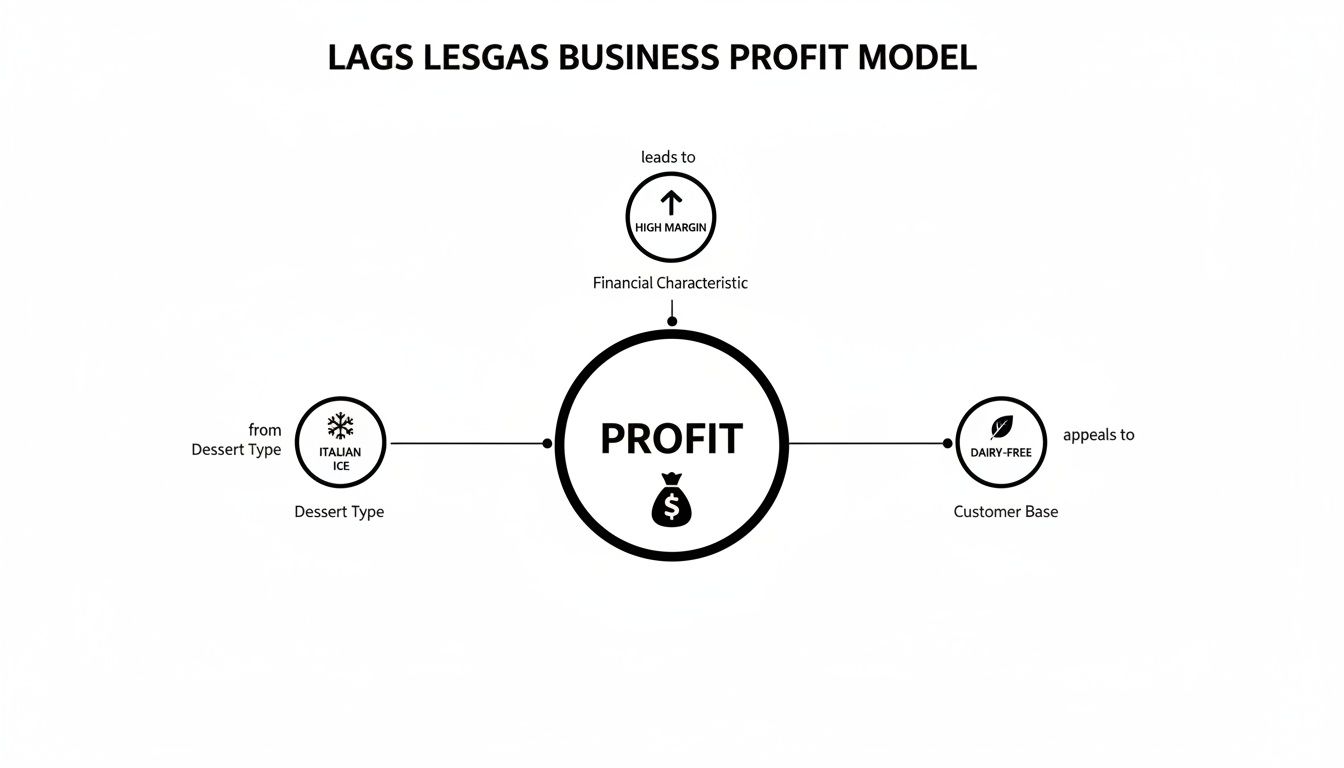

The diagram below breaks down how Italian ice—a high-margin, dairy-free treat—translates directly into profit for a Las Vegas business.

As you can see, the unique qualities of Italian ice tie right into a simple profit model, making it a smart buy for local shops. When you understand these internal parts—the freezing cylinder, the dasher, and the compressor—the technology makes sense. It helps you see why build quality matters and ensures your investment will actually pay for itself.

Choosing the Right Machine for Your Vegas Venue

This is it. Picking the right commercial Italian ice machine is probably the biggest decision you'll make for your new venture. It’s not just about buying another piece of equipment; it's about finding the perfect match for the unique, often insane, rhythm of a Las Vegas business. Nail this choice, and you’re set for smooth operations and lines of happy customers. Get it wrong? You're looking at lost sales, angry customers, and a whole lot of operational headaches.

Think about it: the needs of a quiet little cafe out in Summerlin are a world away from a high-traffic concession stand on the Strip. You wouldn't try to service a massive banquet hall with a small undercounter commercial refrigerator, and you can't expect a tiny Italian ice machine to keep up with thousands of tourists. Your decision has to be based on real numbers—foot traffic, sales goals, and the actual space you have to work with.

Sizing Up Your Options From Countertops to Floor Models

Let's break down the two main types of machines you'll be looking at. It’s a lot like picking a vehicle; you need the right size and horsepower for the job.

-

Countertop Models: These are the compact cars of the Italian ice world. They’re perfect if you're adding Italian ice as another offering on your menu. A food truck cruising through Enterprise or a coffee shop can pop one of these on a counter and serve dozens of people an hour without a huge footprint.

-

Floor Models: These are the heavy-duty workhorses. Built for non-stop production, floor models are an absolute must for any spot where Italian ice is a main attraction. For a packed tourist shop on Fremont Street or a poolside bar at one of the big resorts, this isn't even a question. They’re designed to run all day, every day.

So, how do you choose? It all boils down to one simple question: How many people do you need to serve during your absolute busiest hour? That number is your North Star, guiding you to the right capacity, which we measure in gallons or quarts produced per hour.

Italian Ice Machine Capacity Guide for Las Vegas Businesses

Matching machine output to your venue's daily customer traffic to ensure you meet demand without over-investing.

| Business Type | Typical Daily Traffic (Vegas) | Recommended Machine Capacity (Gallons/Hour) | Model Type |

|---|---|---|---|

| Small Cafe / Bakery | 50-150 customers | 2-4 Gallons | Countertop |

| Food Truck / Small Shop | 150-300 customers | 4-7 Gallons | Countertop or Small Floor |

| Mid-Sized Restaurant / QSR | 300-600 customers | 7-12 Gallons | Floor Model |

| High-Volume Concession | 600+ customers | 12+ Gallons | High-Capacity Floor Model |

This table gives you a solid starting point. A machine that’s too small will leave money on the table, while one that’s too big is just an expensive, underused piece of metal.

Decoding Performance Metrics Freeze-Down and Recovery Time

Okay, so you know the size you need. But output is only half the story. Two other specs are absolutely critical for surviving a scorching Las Vegas summer: freeze-down time and recovery time.

Freeze-down time is pretty straightforward: it’s how long the machine takes to turn your liquid base into perfect, ready-to-serve Italian ice when you first turn it on. Think of it as the time it takes to get the engine warm. A quick freeze-down means you can open your doors and start making money faster.

But recovery time? That’s where the real money is made or lost. This is how fast your machine can freeze a brand-new batch right after you've sold out the last one. A slow recovery time is a profit-killer during a rush. Imagine serving the last scoop, only to tell a long line of overheated tourists they have a 15-minute wait for the next batch. They’re not waiting. They’re walking away, and so is your money.

In a city that never stops, waiting is not an option. A machine with a fast recovery time is your insurance policy against lost sales, ensuring you can consistently meet the surge of customers that defines a successful Las Vegas business.

This is exactly why investing in a quality commercial Italian ice machine pays for itself. A powerful compressor and an efficient freezing cylinder are the keys to minimizing that downtime between batches. It’s what lets you serve an endless stream of customers, maximizing your profit during those peak hours when the desert heat has everyone craving something cold and delicious.

Navigating Installation in a Desert Climate

Installing a commercial Italian ice machine in a typical kitchen is one thing. Trying to do it here in Las Vegas, where kitchen temperatures can easily soar, is a whole different ballgame. The desert climate puts a unique kind of stress on your equipment, making a proper, well-thought-out installation less of a suggestion and more of a survival tactic. A rushed or sloppy setup is a one-way ticket to poor performance, constant breakdowns, and lost money.

Think about it: your entire operation leans on core equipment like commercial refrigerators and commercial freezers. Your Italian ice machine is just as crucial. It needs the right environment and the correct utility hookups from the moment it's uncrated. Getting this right from day one is the only way to ensure your investment works efficiently for years, even when we're in the middle of a brutal summer heatwave.

The Essential Utility Trifecta

Before that shiny new machine even shows up on a pallet, you need to have three key utility connections mapped out and ready to go. These are the lifelines for your new profit center, and dropping the ball on any of them will lead to frustrating delays and unexpected costs.

- Electrical Supply: This is more than just finding an open outlet. Your machine is a powerhouse and needs its own dedicated circuit with the exact voltage and amperage listed by the manufacturer. Trying to share a circuit with other high-draw appliances is just asking for a tripped breaker right in the middle of a dinner rush.

- Plumbing and Water Lines: For any water-cooled models or units with cleaning cycles, a direct water line is a must. But more importantly, the quality of that water is a huge deal. Las Vegas is notorious for its hard water, which is packed with minerals that create scale buildup. This scale is like cholesterol in your machine's arteries, choking off water flow and forcing the compressor to work overtime.

- Proper Drainage: All that water needs a place to go. A floor drain is non-negotiable for most floor models. You have to make sure it's located conveniently and, crucially, that it complies with all Southern Nevada Health District codes to prevent nasty issues like backflow and contamination.

Ventilation: The Unsung Hero of Performance

Here’s probably the most critical piece of the puzzle for any refrigeration equipment in a Las Vegas kitchen: ventilation. Your machine’s compressor is basically a heat engine. Its job is to pull warmth out of the freezing cylinder and dump it into the air around it. If that hot air gets trapped, it creates a pocket of heat that suffocates the machine.

It's like asking someone to run a marathon while wearing a winter coat in July. That’s exactly what you’re making your compressor do without good ventilation. It will overheat, run inefficiently, and eventually burn out, leaving you with an expensive emergency repair bill.

To stop this from happening, you have to give the machine room to breathe. Most manufacturers will tell you to leave at least six to eight inches of open space on all sides that have vents. This clearance allows cool air to be pulled in and hot air to be pushed out, keeping the compressor running at a safe temperature. A well-ventilated machine not only uses less energy and makes Italian ice faster but will also have a much, much longer lifespan.

Avoiding Common Installation Pitfalls

So many installation mistakes are easy to sidestep with just a little bit of planning. The classic error is pushing the machine right up against a wall to save a few inches of floor space, which effectively suffocates the compressor. Another huge one is skipping a water filtration system. Believe it or not, studies show that up to 75% of ice machine service calls are water-related, usually caused by that nasty scale buildup from our local hard water.

If you want to dig deeper into setting up an efficient workspace, take a look at our guide on designing a restaurant kitchen. A smart layout is the foundation of any successful kitchen. By planning your utility connections and guaranteeing plenty of airflow, you're setting your commercial Italian ice machine up for success from the start—ensuring it’s a reliable profit-maker, not a constant maintenance headache.

Keeping Your Machine Spotless: Maintenance And Sanitation

Your commercial Italian ice machine isn't just another piece of kitchen equipment; it's a cash cow. But like any high-performance engine, it needs regular care to keep it humming. Skipping out on maintenance isn't just a bad habit—it’s a one-way ticket to expensive breakdowns, shoddy product, and a potential visit from the health inspector you really don't want.

A well-maintained machine is a profitable one. That’s the bottom line. The buzzing restaurants and shops in Las Vegas are built on quality and consistency. Your customers expect a delicious, safe product every single time they order. The best way to protect your investment and keep your business running without a hitch is to lock down a simple, strict maintenance routine—especially out here in the desert.

Daily Tasks: Your Foundation For Food Safety

The small, consistent things you do every day have the biggest impact. These quick jobs only take a few minutes but are absolutely essential for preventing nasty buildup and making sure your Italian ice is always fresh and safe to serve. Think of it as basic daily hygiene for your machine.

At the end of every shift, make these three things a habit:

- Wipe Down All Exterior Surfaces: Grab a food-safe sanitizer and clean the outside of the machine. Don't forget the handles, spouts, and control panel where hands touch most.

- Empty and Rinse the Hopper: Never, ever leave product mix in the machine overnight. Drain whatever is left and get it stored properly in your commercial refrigerator.

- Flush the System: Run a cycle of clean water or a sanitizing solution through the freezing cylinder. Your manufacturer’s guide will tell you what’s best. This gets rid of residual sugar, which is a breeding ground for bacteria.

Weekly Deep Cleaning: The Non-Negotiable Reset

Once a week, you've got to go deeper than a simple wipe-down. This is when you'll break down and sanitize every part that touches your product. It’s absolutely vital for staying on the right side of the Southern Nevada Health District and stopping mold or slime from taking hold.

Don't forget, the Southern Nevada Health District treats ice as food. Your machine has to meet the same tough sanitation standards as any other food prep surface in your kitchen.

Your weekly deep clean means taking apart all the removable pieces—the dasher, all the seals and gaskets, and the dispensing head. Every single part needs to be properly washed, rinsed, and sanitized, then left to air-dry completely before you put it all back together. This is also the perfect chance to give those seals and O-rings a good look for any cracks or wear. Replace them before they start leaking. If you need a refresher, our guide on commercial ice maker maintenance has some great tips that apply here, too.

Monthly And Long-Term Preventative Care

Long-term care is all about keeping the mechanical parts of your machine healthy. Out here in Las Vegas, one of the biggest enemies of any refrigeration equipment is the fine desert dust that loves to clog up condenser coils.

Make a point to do this once a month:

- Inspect and Clean Condenser Coils: Unplug the machine first! Then, use a stiff brush or a vacuum to gently clear away any dust and gunk from the coils. When they’re clogged, the compressor has to work way too hard, which spikes your energy bill and leads to an early death for the machine.

- Check Lubrication: Some models need a little grease on moving parts like the dasher shaft. Check your owner's manual and use a food-grade lubricant where needed to keep things running smoothly.

- Calibrate Temperature: Use a good thermometer to double-check that your machine is holding the correct temperature. If it's off, you can ruin the texture of your product and create a serious food safety risk.

To really get the most life and efficiency out of your machine, you need a solid preventative schedule. You can find some great general tips in this equipment preventative maintenance checklist. Master this routine, and you’ll guarantee a great product, make your machine last for years, and keep your operation compliant and profitable.

Getting Your Machine the Smart Way

Buying a commercial Italian ice machine is a big move, but the process itself shouldn't be a nightmare. A lot of traditional equipment suppliers are still stuck in the past, operating out of expensive showrooms. You know what that means—all that overhead cost gets baked right into the price tag and passed on to you. For a fast-moving business in Las Vegas, that old model just doesn’t make sense anymore.

We've flipped the script with a modern, showroom-free approach. By running our business online and shipping straight from a central warehouse, we cut out the massive expense of a brick-and-mortar storefront. This lets us offer much better, more transparent pricing on everything from your Italian ice machine to the commercial refrigerators and commercial freezers you need to support it.

It's just a smarter way to get the equipment you need without paying for a fancy showroom you'll never use.

Fast Shipping and Smart Financing

If you're running a food business in Las Vegas, Henderson, or North Las Vegas, you know that time is literally money. You can't afford to sit around for weeks waiting on a critical piece of equipment. That’s why we’ve focused on logistics. We ship directly from a nearby hub in California, which means your new machine can be at your door in just one or two business days—often with free freight shipping.

That kind of speed lets you get your new menu item up and running almost instantly, cutting down on wasted time and helping you see a return on your investment from day one.

In the high-stakes Las Vegas hospitality world, how you manage your cash is just as crucial as what’s on your menu. The right financing lets you get top-of-the-line, efficient equipment without tying up all your capital.

But what about that big upfront cost? For any new or growing business, protecting your cash flow is everything. That's where accessible financing comes in. Instead of taking a huge one-time hit to your bank account, you can break the cost down into predictable monthly payments.

This lets you get the high-quality, dependable ice machines you need to compete right now, while keeping your cash free for other essentials like inventory, marketing, and payroll. It's all about getting the tools for success today, not six months from now when you've saved up. This kind of flexibility means you can invest in quality from the get-go, ensuring your gear is tough enough for the relentless pace of the local market.

Your Questions, Answered

When you're thinking about adding a commercial Italian ice machine to your Las Vegas kitchen, a few key questions always pop up. We get it. From figuring out exactly what makes these machines tick to worrying about the power bill, you want to know you’re making the right call. Here are the answers to the questions we hear most often from local owners.

The restaurant scene here in the vibrant city of Las Vegas is one of a kind, and it demands equipment that can handle the heat—literally. Success depends on having the right tools. You wouldn’t use a bar cooler when you need a powerful commercial refrigerator or a simple chest freezer when a walk-in commercial freezer is required. In the same way, the essential restaurant equipment needed for frozen desserts, like ice machines, must be precisely suited for the job if you want a perfect product every time.

How Is an Italian Ice Machine Different From a Sorbet Machine?

It really comes down to two things: the dasher (the part that churns) and the temperature. A proper commercial Italian ice machine is built to churn at a specific speed and hold a precise temperature. This process creates that classic, smooth-yet-granular texture without whipping in a lot of air (what the pros call "overrun"). It runs a bit warmer than a standard hard-pack freezer, which is crucial for getting that perfectly scoopable consistency.

Try to make Italian ice in a machine built for something else, like sorbet or ice cream, and you'll see the difference immediately. The result is often either rock-hard and dense or, worse, unpleasantly chunky. It's a small detail in the machine's design, but it makes all the difference in the final product.

What Are the Real Energy Costs of Running a Machine in Las Vegas?

This is a big one, especially in our desert climate. An air-cooled machine has to work overtime in the intense Las Vegas heat, and that drives up your electricity bill. The best way to keep those costs in check is to choose an energy-efficient model and—this is critical—make sure it has at least 6-8 inches of clearance around its vents. It needs to breathe.

If you cram your machine into a tight space with no airflow, its compressor will run nonstop just to keep up. We've seen this mistake cause energy costs to spike by as much as 20-30%.

Water-cooled models are generally more efficient in hot climates like ours, but they do come with their own trade-offs, like higher water bills and a more involved installation.

Can I Use My Italian Ice Machine for Other Frozen Desserts?

Absolutely! This is one of the best things about them. Most commercial Italian ice machines are also fantastic for making sorbets, since they share a similar dairy-free base. You can also whip up premium water ices and fruit slushes with no problem.

Where you'll run into trouble is with dairy-based desserts like soft-serve ice cream or frozen yogurt. Those products need a completely different type of machine, one designed to incorporate a lot more air to get that light, creamy texture we all know and love. Before you start experimenting, always double-check the manufacturer's specs to see what your specific model can and can't do.

Ready to add a high-profit, in-demand frozen dessert to your menu? Explore our full range of commercial Italian ice machines and other essential ice machines at Las Vegas Restaurant Equipment. We offer lean, showroom-free pricing and fast, free shipping to the entire Las Vegas area. https://lasvegasrestaurantequipment.com