Walk into any top-tier kitchen in the vibrant city of Las Vegas, from the high-end resorts on the Strip to the local gems in Summerlin, and you'll see the flashy stuff: high-powered ranges, gleaming commercial refrigerators, maybe even a fancy ice machine. But the real workhorse, the unsung hero of the operation, is the humble food storage bin. For any kitchen in a city that caters to every palate, having the right system of restaurant food storage bins is the bedrock of success.

This isn't just about keeping things tidy. These containers are your first line of defense, protecting every single ingredient that comes through your back door.

The Foundation of Kitchen Operations

Think of your kitchen's workflow like a well-rehearsed band. Essential restaurant equipment like the walk-in freezer, the prep tables, the line—they're all the instruments. But the food storage bins? They’re the sheet music. They guide every move, keeping the rhythm steady and preventing pure chaos when the dinner rush hits.

Get it wrong, and you’re looking at:

- Accelerated Food Spoilage: Bad storage is like throwing money directly into the trash.

- Cross-Contamination: This is the big one—a major health hazard that can get you shut down in a heartbeat.

- Gridlock on the Prep Line: When chefs are scrambling to find ingredients, ticket times skyrocket and service grinds to a halt.

- Health Code Violations: The Southern Nevada Health District doesn’t mess around with food storage standards.

A proper storage system isn't an expense; it's an investment in your food quality, your customers' safety, and your bottom line. It directly cuts down on food costs by slashing waste and protects your hard-earned reputation.

This is especially critical here in Las Vegas. The relentless heat and the sheer volume of customers create a unique set of challenges. You've got a constant flow of ingredients coming in and flying out, and the desert climate is unforgiving when it comes to freshness. The right bins work hand-in-hand with your commercial refrigerators, commercial freezers, and ice machines to create a workflow that can actually handle the pressure.

It's no surprise that globally, the food storage container market recently hit USD 163.5 billion. That number tells you just how vital these tools are. You can dig into more data on the global food storage market growth to see just how essential these systems have become for kitchens everywhere.

How to Choose the Right Bin Materials and Designs

Picking the right restaurant food storage bins is a lot like a chef choosing the perfect knife for a specific job. You wouldn't use a paring knife to break down a side of beef, right? The same logic applies here. The bin’s material and design have to match the ingredient and where it’s being stored, whether that’s a chaotic Las Vegas prep line or a sub-zero walk-in freezer.

Getting this choice right is about more than just organization—it’s the foundation for freshness, safety, and a smooth-running kitchen.

Your main options for materials each play a different role. Think of them as specialists on your team, each one perfectly suited for a different task in your commercial refrigerators and commercial freezers.

Understanding Core Bin Materials

To get started, let's break down the three workhorse materials you'll encounter. Each has its own strengths, making them ideal for different zones and workflows within your kitchen.

Comparing Food Storage Bin Materials

This table gives you a quick rundown of the common materials, their best uses, and what makes them tick in a busy kitchen environment.

| Material | Key Benefit | Ideal For | Temperature Range |

|---|---|---|---|

| Polycarbonate | Virtually Unbreakable & Crystal Clear | High-traffic prep areas, storing high-value ingredients, and anywhere you need instant visual identification. | -40°F to 210°F |

| Polypropylene | Budget-Friendly & Chemical Resistant | Storing acidic foods (tomato sauce, dressings), general-purpose storage in walk-ins, and non-perishables. | 0°F to 180°F |

| Polyethylene | Freezer-Grade Durability | Deep freezers and walk-in coolers where other plastics can become brittle and crack. Excellent for bulk frozen goods. | -40°F to 160°F |

As you can see, a smart storage strategy doesn't rely on just one type of bin. It’s all about building a customized system that matches the unique properties of each material to the specific needs of your Las Vegas kitchen.

Let's dig a little deeper into what these materials offer.

- Polycarbonate is the undisputed champion of durability. This stuff is virtually unbreakable, shatter-resistant, and completely clear. That transparency is a massive time-saver, letting your line cooks see exactly what’s inside without ever lifting a lid. Its toughness makes it perfect for high-traffic areas where bins are constantly being moved, bumped, or even dropped.

- Polypropylene is your versatile, everyday player. It's usually translucent or opaque and comes in at a friendlier price point. Its real superpower is its excellent chemical resistance, which makes it the go-to choice for acidic ingredients like marinades or tomato sauces that can stain or damage other plastics.

- Finally, polyethylene is your cold-weather specialist. This material is engineered to stay flexible and durable even at freezing temperatures. It's the only real choice for your deep freezers and walk-in coolers, where other plastics would get brittle and crack under the stress.

The global food container market is booming, expected to hit a staggering USD 94.7 billion by 2035. For a restaurant owner, the benefits are much more immediate and tangible. Storing produce in the right stackable bins can add days to its shelf life, potentially slashing your food waste losses by up to 15%. You can dig into more data on the growth of the food container market if you're curious.

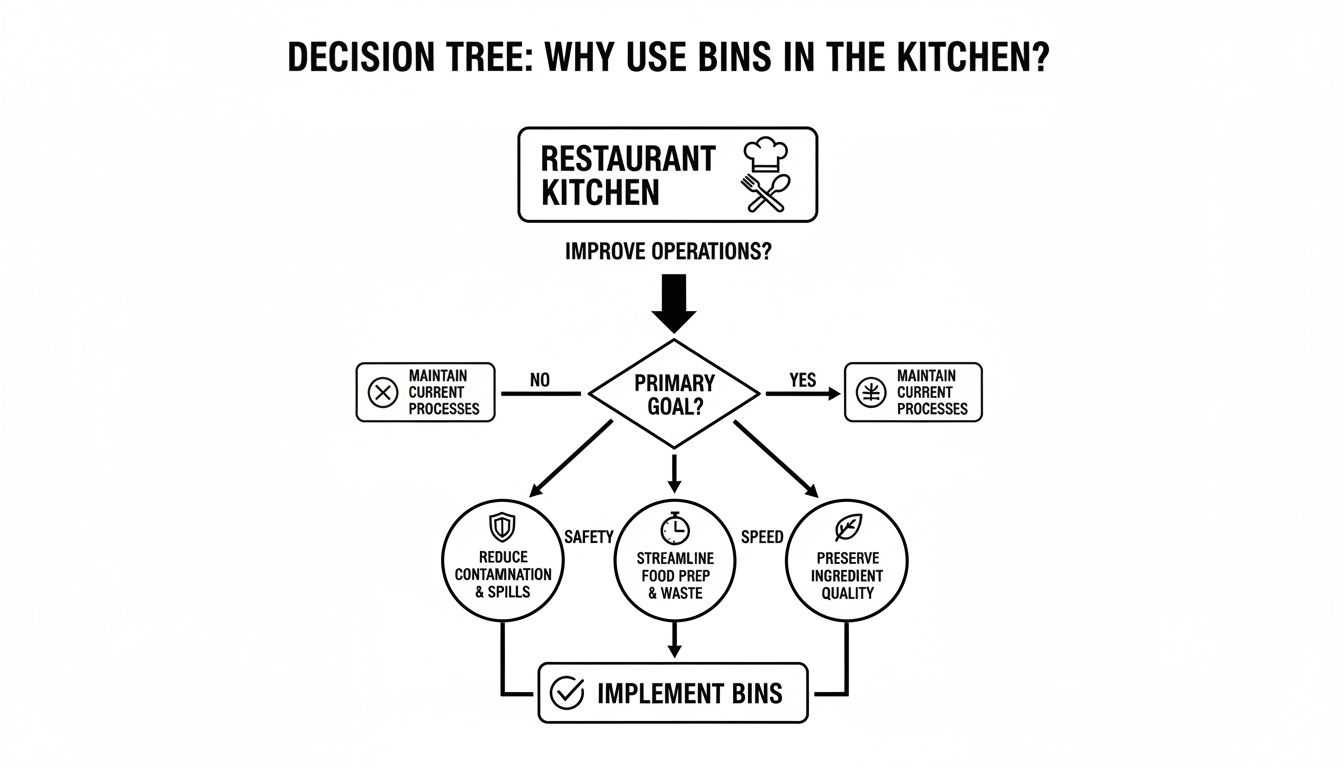

This decision tree shows exactly why a dedicated bin system is a non-negotiable part of a professional kitchen.

As the visual lays out, it all comes down to boosting safety, speed, and the quality of your ingredients. A professional bin system is a direct investment in all three.

Essential Design Features to Consider

Beyond the plastic itself, the physical design of the bin has a huge impact on your daily workflow. Here are the features you absolutely need to pay attention to:

- Stackability: This is a must. Bins with interlocking lids or molded bases are your best friend for maximizing that precious vertical shelf space, especially in cramped Las Vegas kitchens.

- Color-Coding: This is one of the simplest and most effective ways to prevent cross-contamination. Using a color system—like green for produce, red for raw meat, blue for seafood—creates an intuitive visual guide that any staff member can follow instantly.

- Lid Style: The lid you choose depends on the job. Secure, snap-on lids are perfect for locking in freshness for long-term storage. But for a busy prep line, sliding or flip-top lids that allow for quick, one-handed access are a game-changer for speeding up service.

Staying Compliant with Food Safety Regulations

In the high-stakes, high-volume world of Las Vegas dining, food safety isn’t just a good idea—it's a non-negotiable. Whether you're running a massive resort kitchen on the Strip or a beloved local spot in Henderson, the Southern Nevada Health District doesn't play around. Your restaurant food storage bins are on the front line of this battle, acting as one of your most critical tools for keeping inspectors happy and customers safe.

It all starts with a simple seal. When you see that NSF International logo on a bin, it’s more than just a sticker. It's a guarantee. It tells you the container is made from non-toxic materials, is tough enough for the chaos of a commercial kitchen, and has a smooth, non-porous surface that’s a breeze to sanitize. Simply put, using NSF-certified bins is one of the easiest ways to prove you’re serious about safety from the get-go.

Mastering Daily Compliance Practices

Beyond the gear, your day-to-day habits are what really protect your reputation and your diners. The most fundamental practice? The First-In, First-Out (FIFO) system. It’s a simple concept that ensures older inventory gets used before new stock, which dramatically cuts down on food waste and stops expired ingredients from ever making it to a plate.

But FIFO is useless without clear and consistent labeling. Every single bin needs a label that details:

- The name of the product inside.

- The date it was prepped or received.

- The "use-by" or expiration date.

In a fast-paced kitchen, one little labeling mistake can cause huge food waste or, far worse, a foodborne illness outbreak. A disciplined labeling system isn't just about being organized; it's a critical safety control point.

Foolproof Cleaning and Sanitation Protocols

Your storage bins are only as good as they are clean. A solid cleaning protocol is absolutely vital to stop harmful bacteria from building up in tiny cracks or on old food residue. Every bin must be thoroughly washed, rinsed, and sanitized between uses, especially when you're switching from raw chicken to fresh produce, for example.

Proper sanitation is a cornerstone of food safety that touches every piece of equipment you own, including your walk-ins and reach-ins. To dive deeper into how these rules apply to your cooling units, check out our guide on what is a commercial refrigerator.

Keeping every part of your kitchen clean—from the smallest bin to the biggest appliance—is the key to hitting the highest standards. Proper storage and sanitation are the power couple that protects your inventory, your guests, and the future of your business.

Matching Bins to Your Kitchen's Workflow

A really efficient kitchen moves like a well-rehearsed dance, and your restaurant food storage bins are some of the most important dancers. Picking the right bin is one thing, but putting it in the right place within your kitchen's unique flow—that’s what shaves precious seconds off ticket times during a chaotic Las Vegas dinner rush. This isn't just about storage; it's about turning passive containers into active tools that make your crew faster and more accurate.

Think of your kitchen as a collection of zones, each with its own pace and specific needs. The goal is simple: match the bin to the zone's job. When your team has exactly what they need, right where they need it, service becomes seamless.

Zoning Your Storage for Peak Efficiency

Let's walk through a few real-world Las Vegas kitchen scenarios to see how this plays out. By looking at the task at hand, you can pick a bin that doesn't just hold an ingredient but actually helps your staff work better.

-

The Bakery Station: Picture a high-volume Italian spot in the Arts District famous for its fresh pasta and bread. They'll need large, round, food-grade bins for mixing and proofing dough. You'd place these right next to the commercial mixer, which cuts down on movement and keeps flour from flying everywhere, making the whole dough process cleaner and faster.

-

The Cook Line: Now, think about the insane pace of a steakhouse on the Strip. The line cooks need everything prepped and within arm's reach. This is where small, clear, square polycarbonate bins are absolute gold. They line the shelves of the undercounter and reach-in commercial refrigerators, letting chefs instantly spot minced garlic, chopped onions, or portioned steaks without missing a beat.

-

The Walk-In Cooler: Inside your walk-in, organization is everything—for speed and for food safety. For that beautiful fresh seafood flown in for a fine-dining establishment, shallow, perforated bins are a must. They let melting ice drain away, keeping things like branzino or scallops perfectly fresh instead of sitting in a puddle of water. It’s a small detail that makes a huge difference in quality.

Optimizing Dry Storage and Bulk Prep

Your dry storage and bulk prep areas are just as important when it comes to workflow. Simply leaving ingredients in their original sacks or boxes is a recipe for inefficiency and a welcome sign for pests.

Tall, skinny bins with snug lids are perfect for making the most of your vertical shelf space, great for storing bulk pasta, rice, and grains. For a busy cantina prepping gallons of salsa, large square bins with secure lids and measurement markings are a total game-changer. They let your crew mix, move, and store all in one container.

Think about the journey of an ingredient—from delivery, to prep, to the final plate. When you do that, you can choose and place bins that get rid of roadblocks and just make your team's job easier. It's a simple change in thinking that pays off big time in a high-pressure kitchen.

The need for smarter storage is only getting bigger. We're seeing a huge spike in demand for bins with capacities over 2000 ml for bulk restaurant use. A typical restaurant might cycle through 50-100 different bins weekly, and using the right one for each task can preserve 10-20% more inventory value by slashing spoilage. If you want to dive deeper into the numbers, you can discover more insights about the global food container market. The data is clear: a professional storage system is fundamental to running a successful operation.

Maximizing Space with Smart Organization

In a city like Las Vegas where the pace never slows, every single square foot of your kitchen is prime real estate. Transforming a cramped, messy stockroom into a well-oiled machine isn't just about looking tidy—it's about speed, safety, and ultimately, your bottom line. A smart organization system, built around the right restaurant food storage bins, is your secret weapon.

Stacking bins is a good start, but true kitchen optimization goes much deeper. It’s about integrating your bins with specialized equipment that completely changes how you move and manage inventory.

Going Beyond Basic Stacking

Forget just plopping one bin on top of another. To really beat space constraints and make your workflow seamless, you need tools that work with your bins. For any Las Vegas restaurant looking to level up their back-of-house operations, these are total game-changers.

Think about adding these heavy hitters to your lineup:

-

Mobile Dunnage Racks: These are low, wheeled platforms perfect for your heaviest bulk bins. Instead of a cook straining to lift a 50-pound bag of flour, they can just roll the entire rack from the walk-in to the prep station. It’s a huge win for reducing injuries and speeding up prep.

-

Dedicated Shelving Systems: Investing in shelving specifically designed for standard bin sizes is a no-brainer. You get rid of all those awkward gaps and dangerously balanced containers. Everything gets its own home, making your commercial refrigerators and dry storage areas unbelievably neat and functional.

Organization is more than a clean look—it's a system that actively reduces search time, minimizes mistakes, and creates a calmer, more productive kitchen environment, even during the most intense dinner rush.

Using Bins as an Organizational Tool

The design of the bins themselves can radically improve how you handle inventory. For instance, using clear, graduated bins in your refrigerators lets chefs see exactly how much product is left with a quick glance—no lid-lifting required. This kind of visual inventory management saves critical seconds when the ticket machine is screaming.

Color-coding can also be a massive help, and not just for food safety. Try assigning colors to entire zones: maybe blue is for seafood in the walk-in, and green is for produce on the prep line. This creates an intuitive map of your kitchen. It helps new staff learn the ropes faster and ensures everything gets put back exactly where it belongs, every time.

Pairing Bins with Your Essential Kitchen Equipment

Your food storage bins aren’t just standalone items; they’re a crucial part of your kitchen’s whole ecosystem. Their real magic happens when they work in perfect harmony with your most expensive, mission-critical restaurant equipment. For any operator in Las Vegas, getting this synergy right between your bins and your refrigeration is a non-negotiable for protecting inventory and keeping the line moving.

Think of it like a game of Tetris. The goal is to pick bin sizes that fit perfectly on the shelves of your commercial refrigerators and inside your walk-in cooler, making every single square inch count. Bins that are too tall or too wide create dead air space, which is basically like flushing cash down the drain in a high-rent city like Vegas. Switching to standardized, stackable bins can turn a chaotic mess of shelves into a picture of perfect efficiency.

Bins for Specialized Temperature Zones

Different temperatures call for different gear. Your commercial freezers, for instance, are brutal environments where regular plastic can get brittle and shatter in a heartbeat. That’s why using specific freezer-grade polyethylene bins is an absolute must. These containers are built to handle the deep freeze, preventing those costly cracks that lead to spoilage and protecting your expensive proteins from freezer burn.

Your ice machine is another spot where the right bin is everything. The bins you use for ice have to be smooth, easy to sanitize, and used only for ice to stop any chance of cross-contamination.

This whole idea of matching the container to the environment is key to keeping your food safe and top-quality. For example, once you’ve rapidly cooled down hot foods, you need the right kind of storage to hold them at that safe temperature. You can get a better feel for how that works by learning about the role of a commercial blast chiller.

Finally, let's talk about the link between bins and your commercial ice machine. Remember, ice is food, and it needs to be treated with the same level of care.

Here’s a quick guide to choosing the right restaurant food storage bins for your ice system:

- Material: Go for a tough, food-grade plastic that won't chip or crack in the cold.

- Design: Look for bins with super smooth inside surfaces. They're a breeze to clean and sanitize, leaving no place for bacteria to hide.

- Handling: Always—and I mean always—use a dedicated, clean scoop that’s stored outside of the bin. This prevents hand contact and keeps your ice supply pure for every customer’s drink.

Common Questions from the Kitchen

Running a kitchen in Vegas comes with its own set of unique challenges. Here are a few questions we hear all the time from operators on the Strip and beyond about getting their food storage right.

What’s the Most Important Thing to Look for in Bins for a Vegas Kitchen?

In a city of extreme temperatures, your bins have to be tough. Think about it: they go from a scorching hot prep line straight into a walk-in freezer. That kind of temperature shock can make cheap plastic brittle and useless in no time.

You need bins that can handle the swing. Look for materials like polycarbonate or high-density polyethylene—they won't warp or crack. Just as important are tight-fitting lids. The desert dust gets everywhere, and a good seal is your first line of defense in keeping ingredients clean.

How Can Bins Help Me Nail My FIFO System?

This is where clear bins become your best friend. When your line cooks can see exactly what's inside, there's no guessing. Pair that instant visibility with a rock-solid labeling habit: every single container needs the item name, the date it came in, and its use-by date. No exceptions.

Here's a simple trick that works wonders: Always, always place new inventory behind the older stock, whether it's in your commercial refrigerators or on the dry storage racks. It makes grabbing the "First-In" item the easiest, most natural move for a busy crew.

Do I Really Need Special Bins for My Ice Machine?

Yes, you absolutely do. This is a non-negotiable for the health inspector. Your ice is food, and you have to use NSF-certified restaurant food storage bins that are used only for ice.

These bins are made from a food-grade plastic that stays durable at freezing temps. They also have smooth, easy-to-sanitize interiors to prevent any nasty buildup. And always, always use a dedicated scoop that lives outside the bin, never inside it. It’s a simple rule that keeps your ice supply safe and pristine for every drink you serve.

From heavy-duty commercial freezers to the right storage bins for every station, Las Vegas Restaurant Equipment has what your operation needs to thrive. Check out our full catalog and get fast, free shipping at https://lasvegasrestaurantequipment.com.