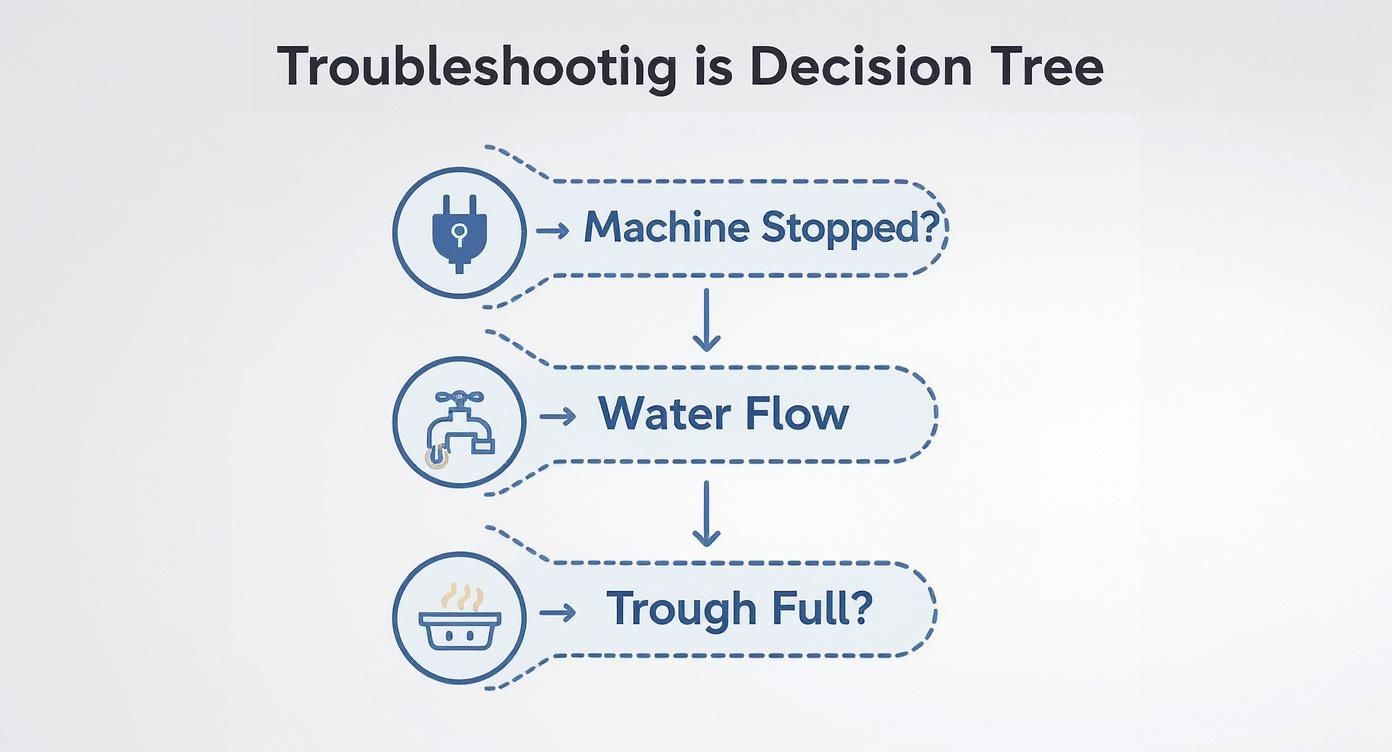

When you're trying to figure out why your Manitowoc has decided to take an unscheduled break, this guide will walk you through the most common culprits, starting with the big one: no ice production at all. The secret is to think like a technician—follow a logical path from the simplest potential problems to the more complex ones.

Diagnosing Why Your Ice Machine Stopped Working

Nothing throws a wrench into the works of a busy restaurant like an ice machine going silent, especially in the vibrant city of Las Vegas. In a city that truly never stops and features a diverse array of restaurants catering to every palate, ice is a non-negotiable commodity. Every spot, from the high-end Strip kitchens to your favorite local diner, depends on essential restaurant equipment for success. This includes reliable commercial refrigerators, high-capacity commercial freezers, and especially their ice machines to keep service flowing. When your Manitowoc quits, it’s more than just an inconvenience; it's a direct hit to your quality of service.

Let’s not forget the intense Las Vegas heat. Kitchen temperatures can skyrocket, putting a ton of strain on any refrigeration equipment. Your Manitowoc is smart—it has safety cut-outs that will shut the unit down if it starts to overheat. This is a good thing, as it protects the compressor from a total meltdown.

Start with the Simple Checks

Before you start tearing things apart, let’s cover the basics. I can't tell you how many service calls I've been on where the fix was something incredibly simple.

- Check the Plug: Is the machine actually plugged in securely? It sounds obvious, but you’d be surprised. Also, take a look at the circuit breaker to make sure it hasn't tripped.

- Open the Water Valve: Find the water supply valve leading to the machine and confirm it’s all the way open. If it’s even partially closed, the machine will be starved for water.

- Inspect the Water Filter: A clogged water filter, whether it's an external one on the wall or the small internal one, is a classic reason for production to stop. It can slow the water flow down to a mere trickle.

This initial diagnostic process is pretty straightforward. You're just making sure the machine has what it needs to even begin the ice-making process.

Following a methodical approach like this ensures you don't waste time assuming the worst when it could be a five-second fix.

Digging Deeper into Mechanical and Environmental Causes

Okay, so the power is on and water is available. Now it's time to look a little closer at what's happening inside the machine and around it.

First, is the water trough filling up like it should? If you know water is getting to the machine but not into the trough, you might be looking at a faulty water inlet valve. Think of it as an electronic gatekeeper; if it’s stuck shut or has failed, the ice cycle never gets the green light to start.

Another key part to check is the high-pressure cut-out switch. This is a safety device that keeps an eye on the pressure inside the refrigeration system.

Pro Tip: In a hot Las Vegas kitchen, the #1 reason for a high-pressure fault is a dirty or blocked condenser coil. The machine can't get rid of heat, so the pressure builds until the safety switch steps in and shuts everything down to prevent serious damage.

This is exactly why keeping those components clean is so critical for keeping your machine running. For a full rundown on how and when to clean everything, our guide on commercial ice maker maintenance has the actionable steps you need. By working through these checks one by one, you can usually nail down the problem fast, cut down on your downtime, and keep your restaurant running without a hitch.

Decoding Manitowoc Error Codes and What to Do Next

When your Manitowoc ice machine starts flashing an error code, don't panic. It's not a sign of disaster; it's the machine's way of telling you exactly where to look for the problem. Think of that control panel as a direct line of communication. In the vibrant city of Las Vegas, where a diverse array of restaurants caters to every palate, knowing how to interpret these codes during a dinner rush can turn a potential crisis into a minor hiccup.

For success, any establishment needs the right restaurant equipment. Your ice machine is just as critical as your commercial refrigerators and freezers, and learning its language is a priceless skill. This section is your translator for those cryptic messages.

Common Codes and Immediate Actions

Let's get right into the codes you'll see most often. Each one points to a specific system, helping you figure out if you're dealing with a quick fix or if it's time to call in a pro.

A huge chunk of service calls boil down to electrical or refrigeration snags. For instance, Code 3 points to a refrigerant issue—either too low from a leak or too high. Code 4 is a classic water temperature problem, meaning your incoming water is too warm (usually over 50°F) and messing up the freeze cycle.

Power-related faults are also incredibly common. We've seen an E03 (Input Power Loss) code account for roughly 15-20% of reported service issues. Then you have sensor errors like E19 (Ice Thickness Probe Fault) and E20 (Water System Fault), which show just how vital those little sensors are. If you want to dig even deeper, Easy Ice has a great in-depth Manitowoc troubleshooting guide with more details.

These codes give you a solid starting point. To make it even easier, here's a quick reference table.

Manitowoc Error Code Quick Reference

| Error Code | Common Meaning | First Action to Take |

|---|---|---|

| E03 | Input Power Loss | Check if the unit is plugged in and the circuit breaker hasn't tripped. |

| E19 | Ice Thickness Probe Fault | The probe is likely dirty. Clean it with a nickel-safe cleaner. |

| E20 | Water System Fault | Check that the water supply valve is fully open and filters aren't clogged. |

| Code 3 | Long Freeze Cycle | Clean the condenser. Check for refrigerant issues (may need a pro). |

| Code 4 | High-Pressure Cutout | Check for high incoming water temperature or a dirty air condenser. |

This table covers the most frequent alerts, but remember, if an error persists, it's signaling a deeper issue.

Your First Response to a Flashing Code

When a code pops up, the gut reaction is to just restart the machine. And sometimes, that actually works! A simple power cycle can clear a minor glitch from a momentary power dip.

To do it safely, flip the power switch to "Off," unplug the machine from the outlet, and give it a full minute. Then, plug it back in and restart.

If that code comes right back, you’ve got a real problem on your hands. Don't ignore it—a recurring code is a surefire way to cause a much bigger, more expensive failure down the road.

A recurring error code is a clear warning sign. For instance, an E19 fault might be a dirty probe you can clean yourself, but if it keeps coming back, it could indicate a failing sensor that will eventually halt ice production entirely.

Interpreting Sensor and System Faults

Many Manitowoc errors come from its network of sensors—the eyes and ears of the control board.

- E19 Ice Thickness Probe Fault: Nine times out of ten, this just means the probe has scale buildup and can't sense when the ice sheet is ready. A gentle cleaning with a nickel-safe solution usually does the trick.

- E20 Water System Fault: This is your cue to check everything water-related. Is the valve shut? Is the filter clogged solid? Is the water pump humming along or silent?

- E03 Input Power Loss: This tells you the machine lost power when it shouldn't have. If the rest of your kitchen is fine, check for a loose plug or a tripped breaker on that specific circuit.

By understanding what these common alerts mean, you can take immediate, informed action. Some solutions are simple fixes you can handle in minutes. Others are clear signs it’s time to call a certified technician to tackle the complex stuff, protecting your investment and keeping your Las Vegas kitchen cool.

Solving Poor Ice Quality and Low Production

Your Manitowoc ice machine is the unsung hero of your restaurant, a workhorse that keeps drinks cold and customers happy. But when it starts putting out small, cloudy ice, or you're running out before the dinner rush even peaks, you've got a performance problem. This isn't just a minor hiccup; bad ice can ruin the taste of a drink and dilutes everything faster, which ultimately hits your bottom line.

In the vibrant city of Las Vegas, where a diverse array of restaurants caters to every palate, consistency is key. Success hinges on having the right essential restaurant equipment, and that includes commercial refrigerators, commercial freezers, and ice machines that perform flawlessly. If the ice machine is lagging, it throws off the whole rhythm of your service. Let's get to the bottom of why your production is weak and get it humming again.

Tuning Up Your Ice Thickness Probe

More often than not, the culprit behind small, weak, or "slushy" ice is a dirty or miscalibrated ice thickness probe. This little metal sensor is the brain of the harvest cycle, telling the control board when the ice sheet is thick enough to drop. If it’s giving a bad reading, the machine harvests way too early.

Think of it like pulling a cake out of the oven after only ten minutes. That's what's happening here—your machine is dropping underdeveloped ice that’s thin and melts in a heartbeat.

Here’s how to check it:

- Find the Probe: It's a small, nickel-plated sensor, usually located near the evaporator plate.

- Look for Buildup: Hard water is notorious for leaving a mineral coating on the probe, which insulates it and triggers false readings.

- Clean It Gently: Use a nickel-safe cleaner and a soft cloth only. Never, ever use an abrasive pad—scratching the probe will ruin it for good.

- Check the Adjustment: The probe can be fine-tuned. Turning the screw clockwise will give you a thicker ice slab, while counter-clockwise thins it out. The factory setting of 1/8 inch (3 mm) is the perfect place to start.

A properly set ice thickness probe is non-negotiable. If it's even slightly off, you'll get a premature harvest, resulting in hollow, thin cubes that just can't hold up in a busy bar or restaurant.

Identifying the Causes of Low Production

What if the ice quality is fine, but the machine just can’t keep up with demand? Now you’re facing a volume issue. A few key factors, especially in a tough environment like Las Vegas, can seriously throttle your output. Most of the time, it boils down to two things: not enough water or too much heat.

An inadequate water supply, whether it’s from low pressure or a clogged filter, is a really common problem. On top of that, a faulty sensor can trick the system into slowing down or stopping completely. And let’s not forget the Nevada heat—ambient temperatures pushing past 110°F (43°C) can slash production in air-cooled models by a staggering 20-30%. You can dive deeper into the technical details about these performance issues and their fixes to get a full picture.

Environmental and Water Supply Checklist

When your production numbers drop, run through this checklist. These are the most frequent culprits that make your machine work overtime for less ice.

- Clogged Water Filters: Always start here. A filter packed with sediment and scale is like a kinked hose—it starves the machine of the water it needs to make ice.

- High Ambient Temperature: Is your machine shoved into a hot, stuffy corner? Air-cooled units have to breathe. If they can’t draw in cool air, they can't shed heat from the refrigeration system, and your freeze cycle will slow to a crawl.

- Dirty Condenser Coils: The condenser is your machine's radiator, and in a busy kitchen, it gets caked with grease and dust. This traps heat, forcing the compressor to run nonstop while producing less and less ice.

- Warm Incoming Water: Manitowoc machines are engineered for water coming in around 50°F (10°C). If your supply water is warmer, the machine wastes precious time and energy just cooling the water down before it can even think about making ice.

Working through these points systematically will help you find the bottleneck. Fixing these issues won’t just get your production back on track; it’ll make the machine more energy-efficient and add years to its life.

Preventative Maintenance That Actually Saves You Money

The best way to troubleshoot your Manitowoc ice machine is to make sure you rarely have to. When it comes to essential kitchen equipment, being proactive is always better—and a whole lot cheaper—than scrambling to fix a problem during a packed Friday night dinner service. Honestly, setting up a simple maintenance schedule is the single most important thing a Las Vegas restaurant manager can do to keep their machine running and avoid those dreaded emergency calls.

In the fast-paced Las Vegas culinary world, every piece of equipment, from your commercial refrigerators to your walk-in freezers, has to be on its A-game. Your ice machine is no different. A little routine care goes a long way, boosting its output, making it more efficient, and dramatically cutting down the risk of an expensive breakdown.

The Critical Role of Condenser Coils

Think of your ice machine's condenser coils as its lungs. In a busy kitchen, they’re constantly breathing in grease, dust, and whatever else is floating around. That gunk builds up and acts like a blanket, forcing the compressor to work overtime just to get rid of heat. This not only wastes energy but can lead to a total system failure.

For any air-cooled model, cleaning these coils is non-negotiable.

- Frequency: In a high-traffic kitchen here in Vegas, I'd check them monthly. If you can see a layer of dust, it's time to clean.

- Technique: First, kill the power to the unit. Then, take a soft-bristled brush and gently clean the fins—always brush in the same direction as the fins so you don't bend them. A vacuum with a brush attachment is perfect for sucking up all the loosened debris.

- The Payoff: Clean coils mean better performance, lower power bills, and much less chance of the machine shutting down on a sweltering summer day.

Keeping your coils clean is just a fundamental part of a well-run kitchen. If you're looking to cut costs across the board, exploring options for energy-efficient commercial refrigeration can lead to some serious savings.

Initiating the Cleaning and Sanitizing Cycle

Beyond the dust and grime you can see, your Manitowoc has a built-in cleaning cycle to handle the scale and slime that builds up inside. Running this cycle regularly is the key to producing ice that’s clear, safe, and doesn't taste like the inside of a machine.

You’ll need two specific things: a Manitowoc-approved descaler for mineral deposits and a sanitizer to kill bacteria. Don't even think about using bleach or anything else; you'll destroy the nickel plating on the evaporator and kiss your warranty goodbye.

The exact steps might differ slightly depending on your model, but the general process is pretty simple:

- First, get all the ice out of the bin.

- Hit the "Clean" or "Wash" button on the control panel.

- The machine will tell you when it’s time to pour the descaling solution into the water trough.

- Once that cycle is done, it will prompt you again to add the sanitizer.

- After the whole thing is finished, the machine rinses itself out and gets back to making ice.

It’s a straightforward process that heads off a ton of potential problems.

It's no secret in the industry: most ice machine failures come down to a lack of basic maintenance. We see it all the time. In fact, industry data shows that 60-70% of problems are a direct result of skipped cleanings and clogged parts.

This isn't just a minor oversight. A dirty condenser can slash your ice production by up to 30% and spike your energy use by 15-25%. The industry-wide push for preventative care has been so successful that it's helped cut down on emergency repair calls by nearly 20% in recent years. Building these simple habits is the best troubleshooting you'll ever do.

Knowing When to Call a Professional in Las Vegas

Look, this guide can walk you through a ton of common Manitowoc issues, but every seasoned kitchen manager knows there's a point where you need to put the tools down. In the non-stop pressure cooker that is the Las Vegas restaurant scene, knowing when to call for backup is just as important as knowing how to descale your machine.

Some problems just aren't a simple DIY fix. They require certified expertise, specialized tools, and a deep understanding of the machine's inner workings. Trying to muscle through a major repair yourself can easily turn a manageable problem into a catastrophic failure, create a serious safety hazard, or even void your warranty.

Red Flags Involving the Sealed Refrigeration System

Here’s the hard and fast rule: never, ever attempt to work on the sealed refrigeration system yourself. This is a closed-loop circuit filled with high-pressure refrigerant. It's not only incredibly dangerous but also illegal to handle without the proper EPA certification.

If you notice any of these signs, your very next step should be to call a certified technician. No exceptions.

- Refrigerant Leaks: Hear a faint hissing sound? See an oily film on the copper lines? That’s a classic sign of a refrigerant leak. Your freeze cycles will get longer and longer until the machine just gives up completely.

- Compressor Problems: The compressor is the engine of your ice machine. If it starts making loud, angry clanking or grinding noises, or if it just hums without actually starting, it's on its last legs. This is a major, complex replacement.

- Temperature Issues: If the machine is running but the lines that are supposed to be frosty are warm (or vice-versa), you've got a serious problem inside the refrigeration cycle. This requires a pro to diagnose properly.

Attempting to fix these issues on your own is a recipe for disaster, risking personal injury and potentially killing your machine for good.

Complex Electrical Faults

Flipping a breaker or checking that a plug is secure is one thing. Diving into the machine’s wiring is another. If you've done the basic power cycle and the machine still won't turn on—or it keeps tripping the circuit—it's time to stop.

You're likely dealing with a short circuit, a dying capacitor, or a fried control board.

From what we've seen, electrical gremlins that don't disappear after a simple reset usually trace back to a failing component like the main board. Keep resetting it, and you risk a cascade failure that turns a single part replacement into a much bigger, more expensive headache.

A pro has the right tools to safely test voltage, read wiring schematics, and swap out delicate electronic parts without causing more damage or risking a nasty shock.

The Value of a Local Las Vegas Partner

For any restaurant in Vegas, having a go-to local service partner is a game-changer. Our extreme desert heat and notoriously hard water put a unique kind of strain on commercial ice machines. A local tech gets it. They've seen it all before and know exactly how to tackle these region-specific problems.

They have the connections to get genuine Manitowoc parts quickly—a crucial advantage when every minute of downtime costs you money. Building a relationship with a trusted local company means you get faster service from someone who understands that in your business, "urgent" is an understatement.

If you’re stuck and need to find a certified pro in the area, don't hesitate to get in touch with our team at Las Vegas Restaurant Equipment. We'll get you pointed in the right direction.

Common Questions Answered

Over the years, we've heard just about every question you can imagine from restaurant managers trying to keep their Manitowoc ice machines running. Here are some of the most common ones we get, with some straightforward advice for what you're likely facing in a busy Las Vegas kitchen.

How Often Should I Really Be Cleaning My Manitowoc?

In a high-volume spot in the vibrant city of Las Vegas, where a diverse array of restaurants caters to every palate, the official manufacturer's line is to do a full cleaning and sanitizing cycle at least every six months. Let's be honest, though—that's the bare minimum.

Around here, with our notorious hard water and desert dust, a quarterly schedule (every three months) is a much smarter play. This keeps the scale buildup from getting out of hand and choking your machine's performance. You should also get in the habit of doing weekly wipe-downs of the air filter and exterior. Success depends on essential restaurant equipment, and consistent care for your commercial refrigerators and commercial freezers pays off—your ice machine is no different.

Why Is There a Puddle of Water on the Floor?

Seeing water on the floor around your ice machine is an immediate red flag, and it usually boils down to one of a few usual suspects. More often than not, you're looking at a cracked water trough, a clogged drain line that’s backing up, or a water inlet valve that just won't close all the way.

Before you do anything else, check the drain for clogs. If that looks clear, take a good look at the water trough for any obvious cracks or damage. One more thing: make sure the machine is completely level. If it’s tilted even slightly, water can easily spill over during the harvest cycle, creating a serious safety hazard.

In a fast-paced Las Vegas kitchen, a leak isn't just a cleanup job—it's a liability. Finding the source quickly can prevent a slip-and-fall accident that could shut you down.

Can I Just Use Any Cleaner on My Manitowoc?

Absolutely not. I can't stress this enough: you have to use the Manitowoc-approved ice machine cleaner (descaler) and sanitizer. Using the wrong chemicals, especially something harsh like bleach, can cause serious, irreversible damage to the machine's internal components.

The nickel-plated evaporator is especially sensitive. The wrong chemical will eat right through it, leading to a massive repair bill and almost certainly voiding your warranty. Stick with the products recommended in the manual to protect your investment.

The Fan Is Running, but I'm Not Getting Any Ice. What's Wrong?

Okay, so the fan is spinning, but no ice is dropping. This tells you the problem is somewhere in the refrigeration or water system. First, listen for the compressor—you should hear a low, steady hum. If it's dead silent, you've likely tripped a high-pressure safety switch. This is a common issue in Las Vegas, often caused by a dirty condenser or just plain high ambient temperatures in the kitchen.

If you can hear the compressor running, the next step is to check the water flow. Is water actually running over the evaporator plate? If it's bone dry, you're probably dealing with a failed water pump or a bad clog somewhere in the line.

No matter the problem, a reliable ice machine is the backbone of any successful restaurant. In the vibrant city of Las Vegas, where a diverse array of restaurants caters to every palate, having the right restaurant equipment is essential for success. If you've done your troubleshooting and it's time for a replacement part, or you're ready to upgrade your commercial refrigerators, commercial freezers, or ice machines, Las Vegas Restaurant Equipment has the warranty-backed, competitively priced gear you need. Check out our full lineup at https://lasvegasrestaurantequipment.com.