That sudden rattle, squeal, or grind from your commercial fridge during a dinner rush isn't just background noise. It's a flashing red light—a warning that something is wrong. Ignoring it is a gamble that could cost you thousands in spoiled inventory.

Your First Response to a Loud Commercial Fridge

In a vibrant city like Las Vegas, with its diverse array of restaurants catering to every palate, a strange noise from essential restaurant equipment needs your attention—now. Whether it's your commercial refrigerator, commercial freezer, or ice machine, you have to quickly figure out if it's just the normal hum of a unit working hard in the desert heat or the sound of real mechanical trouble. The success of your kitchen depends on that equipment, and an unusual sound is the first sign that you're at risk.

Your first move should be calm and methodical. Freaking out can make you miss an easy fix, but pretending you don't hear it could lead to a catastrophic failure. This is your first line of defense to protect your product and stop a small problem from shutting down your line.

Immediate Action Checklist

Before you get on the phone for an emergency repair, run through this quick diagnostic list. You might just have a simple fix on your hands instead of a major issue that needs a pro.

- Pinpoint the Sound: What does it sound like? A constant hum? Repetitive clicking? A high-pitched squeal or a loud grinding? Each noise points to a different issue. A sudden grinding noise is way more urgent than a hum that just got a little louder.

- Check for Vibrations: Sometimes, the noise isn't coming from the fridge itself but from it rattling against something. Make sure the unit isn't vibrating against a wall, shelving, or another piece of kitchen equipment.

- Inspect the Drain Pan: A loose or shifted drain pan is one of the most common culprits for rattling noises. It's usually right at the bottom of the unit, and a quick adjustment can often solve the problem instantly.

- Look for Obstructions: Take a look at the fan guards, both inside the unit and around the condenser coils (usually at the back or bottom). A stray piece of plastic wrap or a fallen box can get in the way and cause a racket.

A steady buzz or hum is often normal. But if it suddenly gets louder, it could be a sign of dirty condenser coils. When they get clogged with dust and grease, they struggle to release heat, forcing the compressor to work overtime. This not only makes more noise but also drives up your energy bill.

To help you decode what your fridge is trying to tell you, here’s a quick reference guide.

Common Fridge Noises and What They Mean

| Noise Type | Likely Cause | Recommended Action |

|---|---|---|

| Loud Buzzing or Humming | Dirty condenser coils or a failing compressor | Clean the coils first. If the noise persists, it's time to call a technician. |

| Rattling or Vibrating | Loose drain pan, fan blade hitting something, or the unit is unbalanced. | Check the drain pan. Look for obstructions near fans. Make sure the unit is level. |

| Squealing or Chirping | Worn out evaporator or condenser fan motor bearings. | This usually means the motor is about to fail. Schedule a repair call soon. |

| Clicking | The start relay is trying to turn the compressor on but failing. | Could be a faulty relay or a sign of a larger compressor issue. Monitor it, but prepare to call a pro. |

| Grinding or Scraping | A serious mechanical failure, likely in the compressor or a fan motor. | Turn the unit off immediately to prevent further damage and call for emergency service. |

Having a basic understanding of your unit’s key parts can also make a huge difference. If you want to get more familiar, you can learn more about what is a commercial refrigerator and how its components work together. This knowledge is invaluable when you have to describe a problem to a technician, helping them diagnose the issue faster when they arrive.

Taking these initial steps can save you time, money, and a whole lot of stress when your equipment acts up in the middle of a busy service.

Diagnosing the Source of Refrigerator Noise

Alright, so you've checked the easy stuff like a rattling drain pan and the noise is still there. Now it's time to put on your detective hat. The specific sound your commercial fridge, freezer, or ice machine is making is the number one clue to what's going on inside.

Figuring out the source isn't about you having to become a full-blown repair technician. It's about gathering some basic intel. This way, when you do call for help, you can give them a clear picture, which can save you a bundle on diagnostic fees right off the bat.

Here in Las Vegas, the biggest enemy of your equipment is often the environment itself. That fine desert dust that gets into everything? It's especially brutal on refrigeration units. It gets sucked into all the mechanical parts, acting like sandpaper on bearings and clogging up the works.

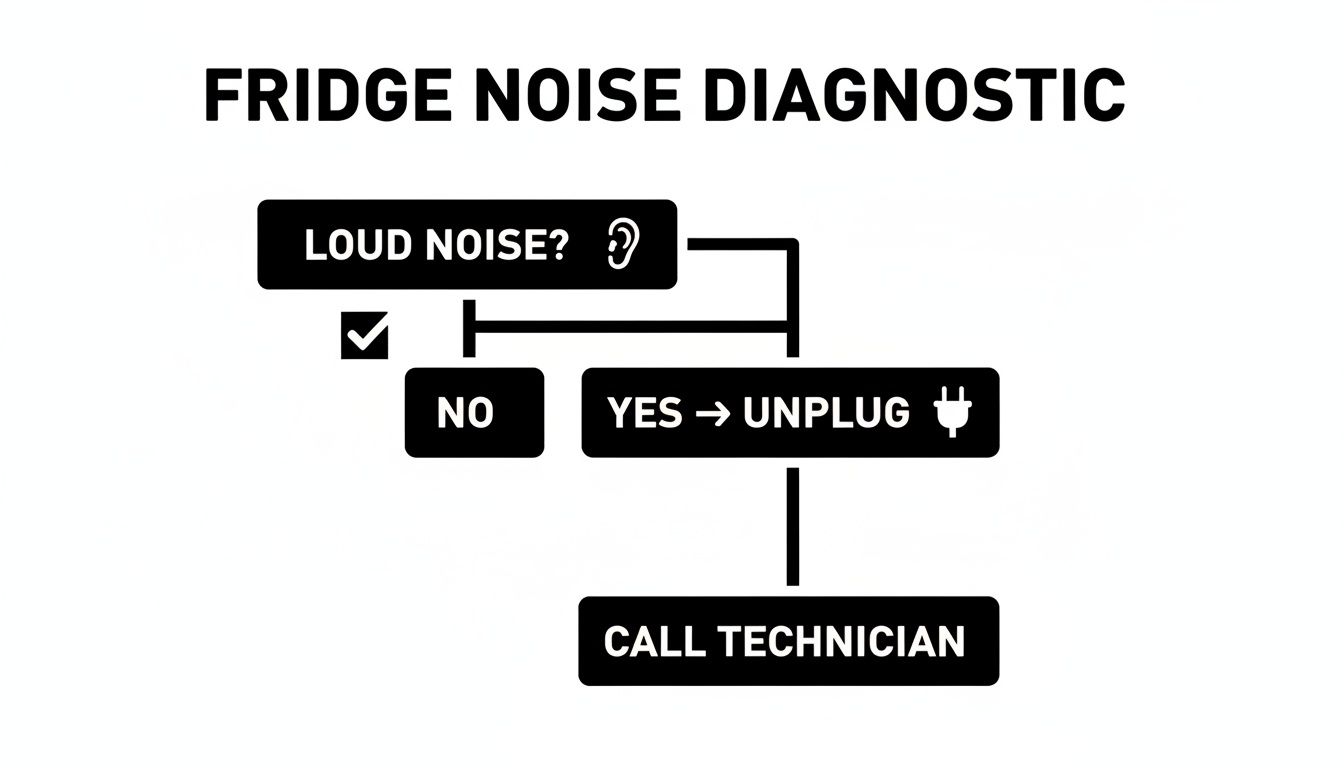

This flowchart gives you a simple, no-nonsense path to follow the moment you hear that something's wrong.

As you can see, the most critical first step—before you even think about looking closer—is to unplug the unit. Safety first, always. It boils the initial reaction down to a clear, safe plan of action.

The Usual Suspects: Common Noise Culprits

To really nail down the problem, you need to listen closely and know where the sounds are coming from. Most of the time, strange noises can be traced back to one of three main components: the condenser fan, the evaporator fan, or the compressor. Each one makes its own unique "I'm in trouble" sound.

- The Condenser Fan: This fan's whole job is to keep the condenser coils and the compressor from overheating. If you're hearing a rattling or a loud whirring sound coming from the back or bottom of the unit, this is your prime suspect. In Vegas, it’s often just choked with dust, which makes the motor strain and can throw the blades off-balance.

- The Evaporator Fan: Tucked away inside the freezer, this fan is responsible for circulating all that cold air. A high-pitched squeal or a persistent chirp usually means its motor bearings are giving up. You might also hear a thumping sound if ice has built up and the fan blades are smacking into it with every rotation.

- The Compressor: This is the heart of your whole system. A healthy compressor just gives off a low, steady hum. But if you hear a loud buzzing, a sharp clicking, or a nasty grinding sound, that's a serious red flag. An overworked compressor fighting against dirty coils will buzz a lot louder than it should.

I see this all the time in Las Vegas restaurants: a windy day kicks up a ton of dust. That dust cakes onto the condenser fan blades and coils. Suddenly, the motor has to work overtime just to spin, creating a loud humming noise. Left alone, this will absolutely lead to overheating and can take out the whole cooling system.

How to Safely Inspect the Components

Before you even think about touching anything, unplug the unit from the wall. I can't stress this enough. Safety is non-negotiable. Once it's completely disconnected from power, you can do a quick visual and manual check.

Start by carefully taking off the rear access panel. This will give you a clear view of the compressor and the condenser fan. Look for any obvious, thick buildup of dust on the fan blades and the coils. Then, gently try to spin the condenser fan blade with your hand. Does it feel stiff? Wobbly? If so, the motor is almost certainly the issue.

Next, move to the evaporator fan inside the freezer. You'll likely have to remove an interior panel to get to it. Check for any ice blockages that might be in the way of the blades. If it's clear of ice but you've been hearing a squealing noise, you can be pretty sure the motor is on its last legs and needs to be replaced.

By confidently spotting these signs, you can give a technician precise info over the phone, which means a faster, more accurate, and often cheaper repair.

Practical DIY Fixes You Can Actually Do

Not every strange sound coming from your commercial refrigerator means you need to brace for an expensive service call. A lot of the time, especially in a demanding Las Vegas restaurant kitchen, common noises are just symptoms of minor issues you can safely and quickly fix yourself. With a few basic tools and a bit of confidence, you can tackle these problems, saving yourself time, money, and a major headache during a busy dinner rush.

Before you even think about touching a screwdriver, do this one thing first: unplug the refrigerator from the wall. This is non-negotiable. It's a critical safety measure that protects you from electrical shock and makes sure all the moving parts, like fan blades, are completely still.

Tackle Dust-Clogged Condenser Coils

In the Las Vegas valley, dust is a constant battle, and your fridge’s condenser coils are right on the front line. When these coils get caked in dust, grease, and grime, they can’t release heat properly. This forces the compressor to work overtime, creating a loud, persistent humming or buzzing sound that just won't quit.

Cleaning them is one of the most effective DIY fixes you can do. You'll usually find the coils behind a grille at the bottom or on the back of the unit.

- After the unit is unplugged, grab a stiff coil brush and gently loosen all that caked-on gunk.

- Follow up with a vacuum cleaner using a brush attachment to suck away all the debris you just knocked loose.

- For a busy restaurant kitchen with stubborn grease buildup, you might need to use a specialized commercial coil cleaner to really get them sparkling.

This simple maintenance task, done every few months, can silence a struggling unit and make it more energy-efficient, which you'll notice on your next power bill.

A buzzing fridge making a loud noise is often just a cry for help from overworked, dirty coils. Spending 15 minutes on a deep clean can often restore peace and quiet—and prevent a much more serious compressor failure down the road.

Before you get started, it helps to have the right gear on hand.

DIY Repair Toolkit for Common Fridge Noises

Here's a quick checklist of the essential tools and supplies you should have in-house to tackle these basic refrigerator noise repairs.

| Tool or Supply | Primary Use | Pro Tip |

|---|---|---|

| Coil Brush | Loosening caked-on dust and debris from condenser coils. | A long, flexible brush works best for getting into tight spaces. |

| Vacuum Cleaner | Removing loosened dust and dirt from coils and fans. | Use a brush attachment to avoid damaging the delicate coil fins. |

| Screwdriver Set | Tightening loose panels, fan mounts, and hardware. | A multi-bit screwdriver will ensure you have the right head for the job. |

| Level | Checking if the refrigerator is balanced on the floor. | A small magnetic level is handy; it can stick to the unit while you adjust. |

| Nut Driver or Wrench | Adjusting the refrigerator's leveling feet. | An adjustable wrench is a versatile option if you don't have a full nut driver set. |

| Flashlight | Inspecting dark areas like the compressor housing or behind the unit. | A headlamp is even better because it keeps both of your hands free. |

Having these items readily available means you can jump on a problem immediately instead of letting it get worse.

Tighten Loose Parts and Secure Panels

The constant vibration from a commercial refrigerator’s compressor and fans can gradually work screws, panels, and other parts loose over time. This is a classic cause of annoying rattling or vibrating noises that can drive your staff crazy.

Take a few moments to do a quick walk-around. Check the access panels on the back and make sure all the screws are snug. Don't forget to look at the drain pan at the bottom of the unit; if it has shifted out of place, it can create a surprisingly loud rattle. Simply repositioning it and tightening any clips can stop the noise instantly.

Level the Unit to Stop Vibrations

If the entire refrigerator seems to be shaking, it might just be off-balance. An uneven floor, which is common in older Las Vegas buildings, can cause the whole unit to vibrate as the compressor cycles on and off. This isn't just noisy—it puts unnecessary stress on the unit’s frame and all the internal components.

Grab a level and place it on top of the fridge. If the bubble isn't centered, start adjusting the feet. Most commercial refrigerators have adjustable legs you can screw in or out to raise or lower each corner. Getting all four feet planted firmly on the ground will often kill that widespread vibrational hum for good.

It’s Not About How Loud It Is—It's About the Kind of Loud

In a bustling Las Vegas culinary scene, it’s easy to think the loudest piece of equipment has the biggest problem. When your walk-in cooler starts rattling the walls, your first instinct is to panic about the noise. But here’s something every seasoned restaurant operator learns: the type of sound your fridge is making is a much better clue than the volume.

A steady, low hum? That's the sound of a successful restaurant in operation. It's the normal, healthy baseline of your cooling system doing its job. But when that hum turns into a sudden grinding, a high-pitched squeal, or a repetitive click-thump-silence, you're hearing a warning shot. Your essential equipment is trying to tell you something is seriously wrong, and learning its language can be the difference between a minor fix and a full-blown emergency.

What Is Your Refrigerator Trying to Tell You?

Think of it this way: the normal hum is just background chatter. A sharp, new sound is a cry for help. Each noise points to a different internal issue, whether it's in your commercial refrigerators, freezers, or ice machines.

- Grinding or Scraping: This is the big one. Nine times out of ten, a grinding noise means a failing compressor or a fan motor with shot bearings. If you hear this, don't wait. It’s a direct path to catastrophic failure.

- High-Pitched Squealing: That ear-piercing squeal is almost always a fan motor on its last legs. The bearings are toast, and it won't be long before it gives up completely, killing your airflow and your cooler's ability to hold temp.

- Repetitive Clicking: Hear a click... click... click... followed by silence? That's likely the start relay on the compressor trying—and failing—to get the system running. This puts a ton of stress on the most expensive part of your unit.

It's all about the character of the noise, not just the decibels. A new, subtle whining sound should worry you more than a loud but consistent fan. Catching these small changes early is how you prevent a total meltdown.

Interestingly, it’s not always the loudest sounds that bother us the most. Research shows that certain frequencies, like whining or rattling, are incredibly annoying even when they aren't very loud. This is why you have to trust your ear. A strange new sound, no matter how quiet, should never be ignored. You can actually read more about how noise characteristics affect perception in refrigeration units to see why that new rattle is getting under your skin.

By listening for the quality of the sound, you can catch a problem long before your food starts to spoil. In a city like Las Vegas, where a downed walk-in can mean thousands in lost inventory overnight, that's not just a good skill—it's essential for survival. It gives you the intel to decide whether you're dealing with a quick DIY fix or if it's time to call in a pro.

Knowing When to Call a Las Vegas Repair Pro

Tackling a noisy fridge yourself can be satisfying, but a smart Las Vegas restaurant operator knows where to draw the line. There's a big difference between confidence and pushing your luck with complex commercial equipment. Getting it wrong can turn a simple service call into a catastrophic failure.

It’s all about protecting your staff, your inventory, and those expensive refrigerators and freezers. You have to know the definitive red flags that scream for professional help. Attempting to fix major electrical or sealed-system issues without proper training isn't just risky—it's dangerous. You could easily cause more expensive damage or, far worse, create a serious safety hazard in your kitchen.

Unmistakable Signs You Need a Technician

If you run into any of these issues with your commercial refrigeration, it's time to put the tools down and pick up the phone. This is not DIY territory.

- A Buzzing Compressor That Won't Start: Hear the compressor hum or buzz, then click off without ever really kicking on? That’s a classic sign of a failing start relay or, worse, a seized compressor. This requires specialized diagnostic tools to sort out correctly.

- Any Electrical or Burning Smells: A burning odor is one of the most serious warning signs you can get. It points straight to overheating wiring or a failing motor, which is an immediate fire risk. Unplug the unit right away and call for emergency service.

- Visible Frost on Evaporator Coils: A thick blanket of frost or ice on the evaporator coils (the ones inside the unit) tells you something is wrong with the automatic defrost system. This goes beyond a noisy fan hitting ice; it’s a sign of a faulty timer, heater, or sensor that an expert needs to diagnose.

- Puddles or Suspected Refrigerant Leaks: Finding puddles of oily liquid or noticing the unit is struggling to cool despite running constantly often points to a refrigerant leak. By law, only an EPA-certified technician is allowed to handle refrigerant.

A fridge making loud noise is an alert, but a burning smell is an alarm. Don't hesitate. The safety of your kitchen and the integrity of your equipment are on the line.

Recognizing these symptoms is crucial. For a deeper look into what goes wrong and how the pros handle it, learning more about commercial refrigeration repair in Las Vegas can give you valuable insight into why these issues demand a professional touch. Making the smart call protects your investment and keeps your business running smoothly.

Preventive Maintenance to Keep Your Kitchen Quiet

The best way to deal with a fridge making loud noise is to make sure it never starts in the first place. In the vibrant Las Vegas restaurant scene, a real maintenance plan isn't just a good idea—it's a survival tactic. Shifting from panic-driven repairs to a steady, predictable schedule is how you protect your most critical assets, from your walk-in cooler to the ice machine.

A simple routine can silence problems before they ever get a chance to derail a busy dinner service. Even better, it makes your equipment run more efficiently, adds years to its life, and keeps your kitchen ready for anything, especially that brutal summer rush. This is how you get that quiet, dependable operation you can count on.

Your Proactive Maintenance Playbook

For any busy Las Vegas restaurant, a maintenance checklist has to be simple and something your crew can actually stick to. The real goal here is consistency, not a complicated to-do list. The easiest way to make it happen is to fold these tasks right into your regular kitchen cleaning schedule.

Here’s a straightforward plan built for the unique challenges of our desert environment:

- Monthly Coil Cleaning: This is the big one here in Vegas. You can't skip it. Dust and kitchen grease are the number one enemy of your refrigeration. When condenser coils get clogged, they make the compressor work overtime, which leads to that loud humming and—you guessed it—higher power bills. Just 15 minutes a month to brush and vacuum the coils on each unit makes a huge difference.

- Quarterly Gasket Inspections: Those rubber door seals (the gaskets) on your fridges and freezers are what keep the cold air in and the hot kitchen air out. If they get damaged, even a tiny tear forces the unit to run constantly just to keep up. Every three months, give them a quick look for cracks and make sure they're creating a solid seal. The old dollar bill trick works perfectly: if you can slide a bill out easily after closing the door on it, that gasket needs some help.

- Bi-Annual Professional Servicing: Twice a year, get a pro in there for a tune-up. The best times are right before and right after the summer heat kicks in. A certified tech can check refrigerant levels, test all the electrical parts, and spot those hidden problems you’d never see otherwise.

A consistent maintenance schedule is your best defense against unexpected downtime. It turns a potential emergency into a predictable expense, saving you from costly after-hours repair bills and lost inventory.

This proactive mindset doesn't just keep the noise down; it has a real impact on your bottom line. Well-maintained units use less electricity, which is a massive win when you're trying to manage operating costs. For restaurant owners serious about savings, checking out energy-efficient commercial refrigeration options can cut utility bills even further while giving you a quieter, more reliable kitchen. By staying ahead of maintenance, you make sure your equipment is working for you, not against you.

When it's time to equip your kitchen with reliable, efficient, and quiet commercial refrigeration, Las Vegas Restaurant Equipment has you covered. We offer a curated selection of new, warranty-backed refrigerators, freezers, and ice machines designed to handle the demands of any Las Vegas restaurant or bar. Explore our inventory and get fast, free shipping at https://lasvegasrestaurantequipment.com.