In the vibrant city of Las Vegas, where a diverse array of restaurants caters to every palate, the freezer unit is the unsung hero of the kitchen. From a massive casino on the Strip to a small local eatery, it’s your first and last line of defense against the brutal desert heat, making it an absolute cornerstone of your business. Picking the right freezer unit for a walk in freezer isn't just a purchase; it's a decision that directly impacts food safety, your monthly power bill, and how smoothly your kitchen runs day in and day out. Essential restaurant equipment needed for success always includes reliable commercial refrigerators, commercial freezers, and ice machines, but the walk-in unit carries the heaviest load.

Your Guide to Freezer Units in the Las Vegas Heat

In the cutthroat culinary world of Las Vegas, where every imaginable cuisine is on the menu, your reputation lives and dies by the reliability of your equipment. Sure, commercial refrigerators and ice machines are important, but the walk-in freezer unit carries the heaviest load, especially when the summer sun is blazing and ambient temperatures can bring an underpowered system to its knees.

A cheap or improperly sized unit doesn’t just struggle to keep things frozen. It becomes an energy hog, sending your utility bills through the roof and putting thousands of dollars of your hard-earned inventory at risk. This guide is your no-nonsense roadmap to making a smart, long-term investment.

Key Considerations for Your Operation

Before we get into the nuts and bolts, let's talk about the unique challenges of our Nevada climate. The intense, dry heat puts an incredible amount of stress on refrigeration components, making durability and proper sizing completely non-negotiable. When you're looking at options, it's wise to consider specialized cooling solutions for Las Vegas that are built to handle our extreme environment.

For a deeper dive into how modern tech can help you keep those operational costs down, you can learn more about energy-efficient commercial refrigeration options.

Think of your freezer unit as an insurance policy for your inventory. A powerful, correctly sized system is what protects your assets from spoilage. It's what ensures your kitchen can deliver quality, day after day, even when it’s 110°F outside.

We're going to break down the must-know topics you need to master:

- System Types: We'll look at the critical differences between remote and self-contained units and figure out which makes sense for your space.

- Sizing and Capacity: This is all about how to calculate the real cooling power (BTUs) you need for your specific walk-in size and product load.

- Installation Essentials: We’ll cover the ventilation and electrical requirements that guarantee your unit runs reliably for years to come.

Armed with this information, you'll be ready to choose a freezer unit for your walk in freezer that’s truly built to survive—and thrive—in a Las Vegas kitchen.

Remote vs. Self-Contained Freezer Systems Explained

When you're choosing a freezer unit for a walk-in, the first big decision you'll make comes down to the core design. You have two main paths to go down: self-contained systems and remote systems. Each one works differently and has its own set of pros and cons, especially when you're dealing with the intense heat of a Las Vegas kitchen.

The All-in-One Approach: Self-Contained Units

Think of a self-contained freezer unit like a window AC unit for your walk-in. The whole system—compressor, condenser, evaporator, everything—is built into one single, self-contained box. This makes installation pretty straightforward and usually cheaper upfront because you don't have to run a bunch of refrigeration lines.

But there's a major catch to that convenience. The unit dumps all its heat and noise right into the room it's in, which is probably your already hot and chaotic kitchen. In a place like Las Vegas, where kitchen temps can skyrocket, adding another big heat source is the last thing you want. It puts a huge strain on your main HVAC, drives up the ambient temperature, and makes life miserable for your staff.

The Smart Money Bet: Remote Systems

A remote freezer unit, on the other hand, is set up more like your home's central air conditioning. It’s a "split system," which just means the loud, heat-generating parts (the condenser and compressor) are installed separately from the indoor evaporator coil. That noisy condensing unit gets placed outside—usually on the roof or tucked away behind the building.

For any serious Las Vegas restaurant, that separation is a game-changer. By moving the heat and noise outside, a remote system keeps your kitchen cooler, quieter, and running more efficiently. Yes, the installation is more involved and costs more at the start, but the long-term payoff—a lower heat load in your kitchen and reduced cooling bills—almost always makes it the right call.

For a busy Las Vegas kitchen battling intense summer heat, a remote system is more than a piece of equipment; it's a strategic decision. It actively works to lower the ambient temperature in your workspace, improving both employee comfort and the efficiency of other kitchen appliances.

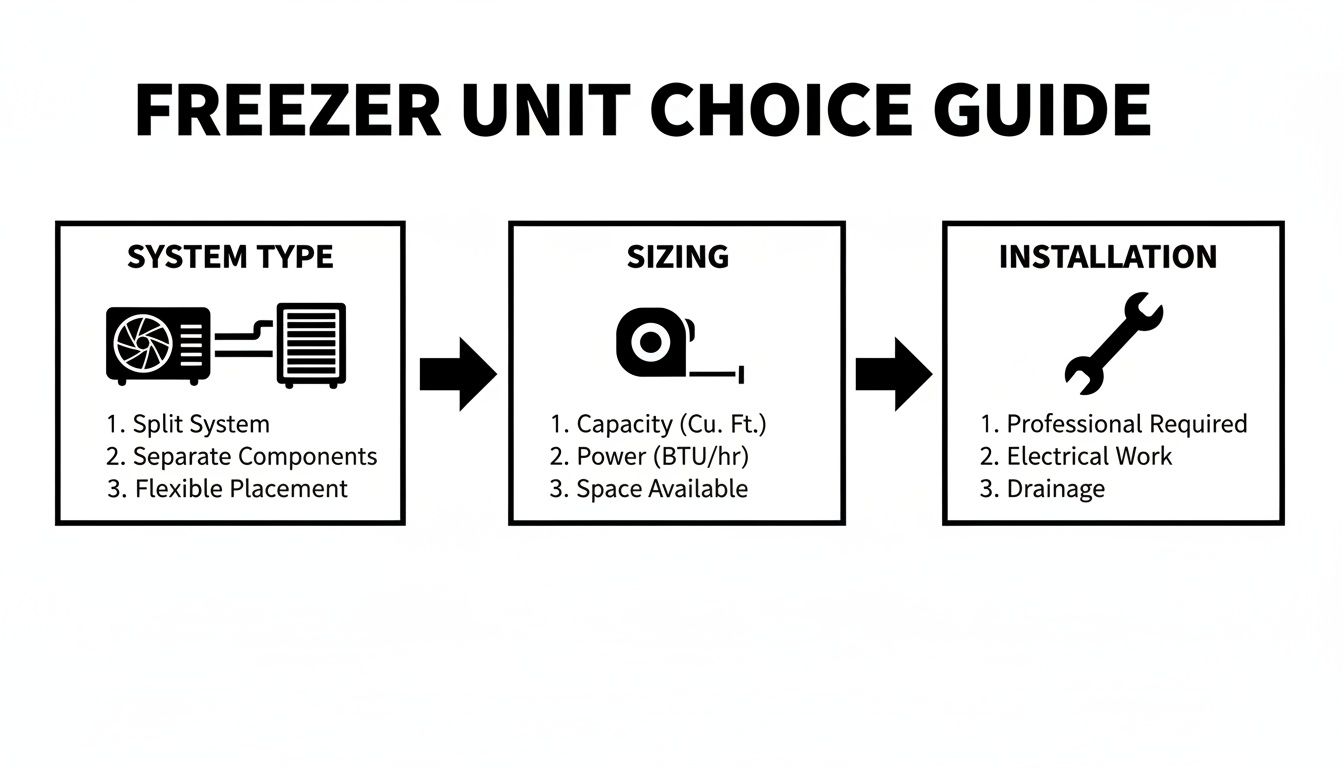

The flowchart below breaks down the key decision points for picking a system type, sizing it right, and planning the installation.

As you can see, the type of system you choose has a direct impact on how you'll need to calculate its size and handle the installation.

Self-Contained vs Remote Freezer Unit Comparison

To really figure out what’s best for your restaurant’s layout and day-to-day operations, it helps to see the options laid out side-by-side. The right freezer unit for a walk-in freezer depends entirely on your space, your budget, and what you’re planning for the long haul.

| Feature | Self-Contained Unit (All-in-One) | Remote Unit (Split System) |

|---|---|---|

| Heat & Noise | Vents directly into the kitchen, increasing ambient heat. | Moves heat and noise outdoors, creating a cooler kitchen. |

| Installation | Simpler and faster, often with lower upfront labor costs. | More complex, requiring refrigeration lines and outdoor placement. |

| Initial Cost | Generally lower due to the all-in-one package design. | Higher initial equipment and installation costs. |

| Best For | Smaller kitchens, budget-conscious setups, or locations with outdoor space constraints. | High-volume restaurants, kitchens sensitive to heat, and long-term efficiency goals. |

| Energy Impact | Can increase the load on your kitchen's main HVAC system. | Reduces the kitchen's heat load, potentially lowering overall cooling bills. |

Making the right choice here is a serious investment, and it reflects a huge trend in our industry. In the tough world of commercial kitchens, especially in a city like Las Vegas, the global market for walk-in coolers and freezers hit a massive USD 10.215 billion. North America is the biggest player, with almost 50% of the market share, all driven by strict food safety rules and the non-stop growth of restaurants.

For operators here in Nevada, this just drives home how critical it is to invest in a bulletproof freezer unit that can handle the "Sin City" heat while saving you money on energy bills. You can discover more about these market trends and see how they're shaping the industry.

How to Correctly Size Your Walk In Freezer Unit

Picking the right freezer unit for your walk-in isn't just about matching it to the box's dimensions. It's a critical calculation, and getting it wrong is a recipe for disaster—spoiled inventory, shocking energy bills, and a system that gives up the ghost right when you need it most. This is doubly true here in Las Vegas, where a unit that works just fine in a milder climate will be pushed to its absolute breaking point during our brutal summer months.

Think of it like choosing an engine for a truck. A little four-cylinder is great for cruising around town, but it’s going to stall out trying to haul a heavy load up a steep mountain pass. In the same way, an undersized freezer unit will run constantly, struggle to hold temperature, and eventually fail when it hits the "mountain" of a Las Vegas heatwave.

Beyond Box Size: The Key Sizing Factors

The first thing to get straight is that the physical size of your walk-in—let's say an 8' x 10'—is just one piece of the puzzle. To really pin down the cooling power you need, measured in British Thermal Units (BTUs), you have to account for every single source of heat the unit will be fighting against.

This "heat load" comes from a few different places, and each one has to be factored into your math to get a reliable result in our demanding environment.

- Walk-In Box Dimensions: The length, width, and height set the total volume of air that has to be kept frozen solid. A bigger space naturally demands a more powerful unit.

- Insulation Quality: The R-value of your walk-in panels is huge. Thicker, higher-quality insulation (usually 4-5 inches for a freezer) acts like a fortress wall, keeping heat out. Weak insulation means your unit is constantly battling a heat invasion.

- Ambient Temperature: For any Las Vegas restaurant, this is the big one. Your kitchen's temperature, especially in the summer, is the single greatest challenge to your unit. A system rated for an 85°F environment will be completely overwhelmed when your kitchen hits 100°F.

- Product Load: How much stuff are you loading into the freezer every day, and how warm is it when it goes in? Bringing room-temperature food down to 0°F sucks up a massive amount of energy.

Calculating Your BTU Requirement: The Las Vegas Method

BTUs are simply the standard measurement for heat removal. A higher BTU rating means the unit can yank more heat out of the box in a set amount of time. To size a unit correctly for our climate, you have to plan for the absolute worst-case scenario.

The process involves tallying up the heat load from four main sources:

- Transmission Load: This is the heat seeping in through the walls, ceiling, and floor.

- Air Change Load: Every time that door swings open, a blast of warm, humid kitchen air rushes in, and the unit has to chill it all back down.

- Product Load: This is the energy it takes to freeze the actual food you're putting inside.

- Miscellaneous Load: This covers the heat thrown off by lights, evaporator fans, and even people working inside the box for a few minutes.

For Las Vegas restaurateurs, the golden rule is this: calculate your needs for a peak summer day, and then add a buffer. Sizing a unit for an "average" day guarantees it will fail on the hottest day of the year. You have to oversize it slightly to build in a safety margin.

This is the only way to ensure your unit can handle the strain of a 110°F day without putting your food safety at risk.

Why Ambient Temperature Is a Deal-Breaker

Let’s make this real. A standard freezer unit might be rated to work perfectly in an ambient temperature of 90°F. But on a slammed Friday night in July, a Las Vegas kitchen can easily soar past that. When the air around the condenser gets too hot, it can't get rid of the heat it's pulled from the freezer, and its cooling efficiency plummets.

This is exactly why a freezer unit for a walk in freezer heading to a Nevada kitchen has to be specified for high-ambient conditions. Many manufacturers build models just for hotter climates, equipping them with bigger condenser coils and beefier components that won't buckle under the pressure. If you're considering an all-in-one setup, understanding the points in our guide on walk in cooler and freezer combos can offer some valuable perspective on managing that heat load.

Ignoring this one factor is the single most common—and most expensive—mistake a restaurant owner can make. Have an honest conversation with your equipment supplier about what your kitchen actually feels like in the summer. That's how you get a unit engineered to perform, protecting your inventory and your sanity.

Mastering Your Freezer Unit Installation

You can have the most powerful, perfectly sized freezer unit on the market, but if it's not installed correctly, none of that matters. For a busy Las Vegas restaurant, a botched installation isn't a minor hiccup—it's a direct threat to your inventory and your bottom line. Getting the setup right from the very beginning is the only way to guarantee safety, peak performance, and a long life for your equipment.

The whole game really comes down to two things: electrical readiness and proper ventilation. One gives the unit the juice it needs to run safely, and the other gives it room to breathe, which is absolutely non-negotiable in our desert heat. Skimping on these basics is a recipe for premature equipment failure and an energy bill that will make your eyes water.

The Non-Negotiable Electrical Requirements

Your new freezer unit is a beast. Just like a commercial refrigerator or a high-volume ice machine, it pulls a lot of power. That’s why it absolutely requires a dedicated electrical circuit. No other appliances can share its power source, period. This is how you prevent overloaded circuits that trip breakers and shut down your entire freezer in the middle of a dinner rush.

Before the installation crew even thinks about showing up, your electrician needs to have the site prepped and ready.

This means:

- A Dedicated Circuit: The freezer unit needs its own personal breaker in your main electrical panel.

- Correct Voltage and Amperage: The power supply has to exactly match what the manufacturer specifies. A mismatch here can fry the compressor for good.

- Properly Installed Outlet: A heavy-duty, commercial-grade outlet must be within easy reach of the unit’s power cord. Extension cords are a major safety hazard and are not an option.

Trust me, waiting on an electrician is one of the most common and maddening delays in any kitchen build-out. Make sure the electrical is ready, inspected, and signed off on before your delivery day. It's the key to a smooth, on-schedule installation.

Ventilation: The Secret to Las Vegas Efficiency

In the brutal Las Vegas climate, ventilation isn't just a good idea—it's the single most important factor for your freezer unit's efficiency and lifespan. The whole system works by yanking heat out of the walk-in box and dumping it into the air outside. If that surrounding air is already hot and stagnant, the unit simply can't cool itself down.

For a self-contained unit inside your kitchen, this means giving it plenty of personal space. The unit needs clearance on all sides to pull in cool air and push out hot air. Shoving it into a tight corner is a guaranteed way to make it overheat and work itself to death, sending your energy consumption through the roof.

For a remote system, where the condenser is outside, placement is everything.

The goal is to position the outdoor unit where it has unrestricted access to the coolest, cleanest air possible. This is your best defense against the intense ambient heat of a Las Vegas summer, allowing the system to shed heat efficiently and keep your energy costs in check.

Ideally, you’ll want the condenser on the north or east side of the building to dodge that relentless afternoon sun. It's also critical to place it in a well-ventilated spot, far away from other heat-blasting equipment like your HVAC units. A successful installation depends on knowing how all the parts work together. For a deeper look at the electrical components, our guide on mastering contactor installation is a great resource. By making ventilation a priority from day one, you’re protecting your investment and setting your kitchen up for success.

A Practical Maintenance Checklist for Peak Performance

Let’s be honest: preventative maintenance is the single most effective tool you have against a costly, middle-of-service breakdown. For any Las Vegas restaurant, keeping your freezer unit in top shape isn’t just about dodging repair bills. It’s about protecting thousands of dollars in inventory, keeping your energy costs in check, and making sure your equipment can survive the brutal summer heat.

Think of your freezer unit for a walk in freezer like the engine in a high-performance car. You wouldn't skip an oil change and expect it to run flawlessly, right? The same logic applies here. Ignoring simple maintenance tasks will absolutely lead to lower efficiency, shocking power bills, and eventually, a catastrophic failure that could shut down your kitchen.

Daily and Weekly Checks

The best way to keep your freezer reliable is to build simple, consistent habits. These are quick tasks you can fold into your kitchen’s opening or closing routines, and they make a huge difference in catching small problems before they blow up.

- Check the Temperature: Glance at the thermostat. Is it holding steady between -10°F and 0°F? If it's bouncing around, that's your first red flag.

- Listen for Odd Noises: You know the normal hum of your unit. If you suddenly hear new grinding, rattling, or an unusually loud buzz, it’s time to investigate.

- Inspect Door Seals: A quick and easy one. Run your hand along the door gasket. If you feel a draft of cold air, that seal is compromised, and your unit is working overtime to compensate.

- Clear Debris: Make sure boxes, trash, or anything else isn't blocking the fans inside or the condenser unit outside. Good airflow is everything.

The impact here is real. Commercial kitchens are the main reason the walk-in freezer market is projected to hit USD 5.30 billion. That growth is all about managing inventory, and studies show that up to 30% of food waste in commercial kitchens is directly tied to poor refrigeration. A solid maintenance plan protects that bottom line. You can discover more insights on the commercial freezer market to see just how big this is.

Monthly and Quarterly Tasks

Going a little deeper on a regular schedule will add years to your unit's life. These next steps are focused on keeping the core components clean, which is non-negotiable in the dusty Las Vegas environment.

A clean refrigeration system is an efficient one. Dust, grease, and grime act like an insulating blanket on your coils, forcing the compressor to run longer and harder to remove heat. This is the number one cause of high energy bills and premature component failure.

Get these essential steps on your calendar for every one to three months:

- Clean Condenser Coils: For remote units, the outdoor coil is a magnet for dust. Gently brush the fins or use a shop vac to clear them out. If you have a self-contained unit, the coils are in the kitchen collecting grease—you’ll need a specialized coil cleaner to cut through it.

- Clean Evaporator Coils and Fan: Inside the walk-in, gently clean the evaporator coil and fan blades. Any significant ice buildup here means you might have a defrosting issue.

- Check and Clear Drain Lines: Make sure the condensate drain line is flowing freely. If it’s clogged, you’ll get water backup and ice forming where it shouldn't.

- Inspect Electrical Connections: Take a look at the wiring. If you see anything frayed or loose, it's a job for a qualified technician unless you have the expertise.

Making a Smart Investment in Your Restaurant

Buying a new freezer unit for a walk in freezer isn't just another line item on your expense sheet—it's a critical investment in your restaurant's future. Here in the cutthroat Las Vegas food scene, consistency is king, and the right equipment is the bedrock of quality. It pays to think like a business owner and prioritize long-term reliability over a quick, cheap fix.

That all starts with certifications. You absolutely cannot compromise on this. Look for units that are NSF (National Sanitation Foundation) and ETL (Intertek) certified. These aren't just fancy stickers; they're your guarantee that the equipment meets strict public health and safety standards. For any restaurant, hotel, or food truck in Vegas, certified gear is a must-have to pass health inspections and keep your customers safe.

Smart Purchasing and Financing Strategies

Dropping a ton of cash on new equipment doesn't have to sink your budget. Smart moves, like buying from an online retailer that doesn't have a pricey showroom, can slash the final cost. Without that massive overhead, the savings get passed directly to you, putting top-tier commercial refrigerators and freezers within reach.

On top of that, financing is a total game-changer, especially for new or growing Vegas restaurants. Instead of one massive upfront payment, you can spread the cost over manageable monthly installments. This keeps your cash flow healthy for other essentials like payroll, inventory, and marketing, so you can get the high-quality gear you need to compete without breaking the bank.

Think of certifications and smart financing as the two pillars holding up your investment. Certifications protect you from compliance headaches and ensure food safety. Financing makes the best equipment affordable right now, setting you up for success from day one.

Choosing the right brand is a huge part of the puzzle, and it helps to know who the major players are. You can check out our breakdown of the best commercial freezer brands to see which manufacturers have a reputation for holding up in demanding kitchens like ours.

Finally, a solid warranty is your ultimate safety net. It’s the manufacturer's promise to stand by their product, giving you peace of mind that you won't be left high and dry if something goes wrong. By focusing on certified, well-warrantied equipment and taking advantage of smart purchasing options, you’re not just buying a machine—you’re securing your restaurant’s stability and future growth.

A Few Common Questions We Get About Freezer Units

When you're running a busy restaurant in Las Vegas, the last thing you have time for is troubleshooting your walk-in freezer. You just need it to work, period. To help you stay ahead of any issues, here are some straightforward answers to the questions we hear most often about freezer units.

How Often Do I Need to Defrost My Walk-In?

Here's the good news: you shouldn't have to. Modern commercial freezers handle this all on their own with automatic defrost cycles. These systems are smart, using timers or sensors to gently heat the evaporator coils just long enough to melt off any frost before it becomes a problem. This keeps air flowing freely and your unit running at peak efficiency.

If you do see a serious ice buildup, it’s a red flag that something else is wrong. You might have a bad door gasket letting in humid desert air, a faulty defrost heater, or a drain line that's clogged up. Instead of chipping away at the ice, you need to find the real culprit.

What's the Right Temperature for a Walk-In Freezer?

For food safety and to keep your inventory in top shape, your walk-in freezer needs to stay at or below 0°F (-18°C). That’s the industry standard. Many Las Vegas chefs I know actually set theirs a bit colder, down to -10°F (-23°C), which gives them a safety buffer for when the door is swinging open constantly during a dinner rush.

Remember, holding the right temperature isn't just a suggestion—it's a non-negotiable for food safety. It completely halts bacterial growth and locks in the flavor and texture of thousands of dollars worth of product.

Getting into the habit of glancing at your unit's external thermometer every day is one of the simplest, most effective maintenance checks you can do.

Can I Just Stick an Indoor Freezer Unit Outside?

Please don't. This is a question we get more than you'd think, and the answer is always a hard no. Indoor and outdoor units are engineered for completely different worlds. An outdoor condensing unit is built like a tank, with a weatherproof shell designed to fend off everything from monsoon rains to the brutal Las Vegas sun.

Putting an indoor unit outdoors won't just instantly void your warranty; it’s a recipe for disaster. You're looking at quick component failure and a genuine electrical fire hazard. Always buy the right unit for the job—it’s crucial for the safety of your staff and the longevity of your investment.

Ready to find a freezer unit that can actually keep up with the Vegas heat? At Las Vegas Restaurant Equipment, we hand-pick our inventory of Atosa commercial refrigerators and freezers because we know they're built to last. Check out our equipment online or give me, Sean Kearney, a call directly for some expert advice that’s actually tailored to your kitchen.