When your ice maker goes down, the first instinct might be to panic. Before you do anything else, run through the absolute basics: Is the machine plugged in and getting power? Is the water supply valve open? Are the temperature settings correct? You'd be surprised how often one of these simple checks solves the problem and saves you an expensive service call.

If the fix isn't that easy, don't worry. This guide will walk you through the next steps for diagnosing what’s really going on.

Your Ice Machine Is a Mission Critical Asset in Las Vegas

Here in Las Vegas, an ice machine isn't just another appliance—it's the lifeblood of your operation. In this vibrant city, you'll find a diverse array of restaurants that cater to every palate, from fine dining on the Strip to bustling downtown bars and high-volume casino floors. For all of them, a steady supply of clean ice is completely non-negotiable. It’s a core part of the guest experience, from the quality of a signature cocktail to basic food safety.

An ice machine failing during a Friday night rush isn't a minor headache; it's a direct blow to your revenue and reputation. That's why having a solid grasp of commercial ice maker troubleshooting is so vital. When that machine suddenly stops, starts making weird noises, or springs a leak, your team's ability to quickly figure out what's wrong can mean the difference between a small hiccup and a full-blown operational crisis.

The Backbone of Your Operation

Success in the Las Vegas food scene requires the right tools. Think of your ice machine as the silent, hardworking partner to your other essential restaurant equipment, including commercial refrigerators, commercial freezers, and ice machines. It underpins the entire service flow, making sure drinks are served cold and food preservation standards are always met. Its reliable performance is fundamental to the high level of service that defines the Vegas experience.

This guide is your roadmap for getting to the bottom of the most common issues. We'll dig into the frequent culprits behind ice machine failures, including:

- The machine suddenly stops making ice altogether.

- Production is way too slow or just not keeping up.

- You find a puddle of water around the unit.

- You hear strange grinding, rattling, or banging sounds.

The goal here is to give you the confidence to tackle many of these problems yourself, saving you precious time and the cost of an emergency repair visit. This hands-on approach doesn't just keep your business running smoothly; it helps extend the life of your equipment. Keeping all your major appliances in peak condition is key, which is why looking into topics like energy-efficient commercial refrigeration can pay off big in the long run.

The industry's reliance on these machines was thrown into sharp relief during recent global events. The commercial ice maker market took a major hit when the hospitality sector—its biggest customer—faced shutdowns and slow business, leading to a huge drop in demand. You can get a deeper look at these market shifts in this commercial ice maker market report.

Solving No Ice or Slow Production Problems

Nothing kills the mood in a bustling Las Vegas kitchen faster than an ice machine that decides to take a break. When that bin stops filling up or the production slows to a trickle during a dinner rush, you've got a real problem. But before you panic and call for backup, the good news is that many of the usual suspects are surprisingly easy to track down and fix yourself.

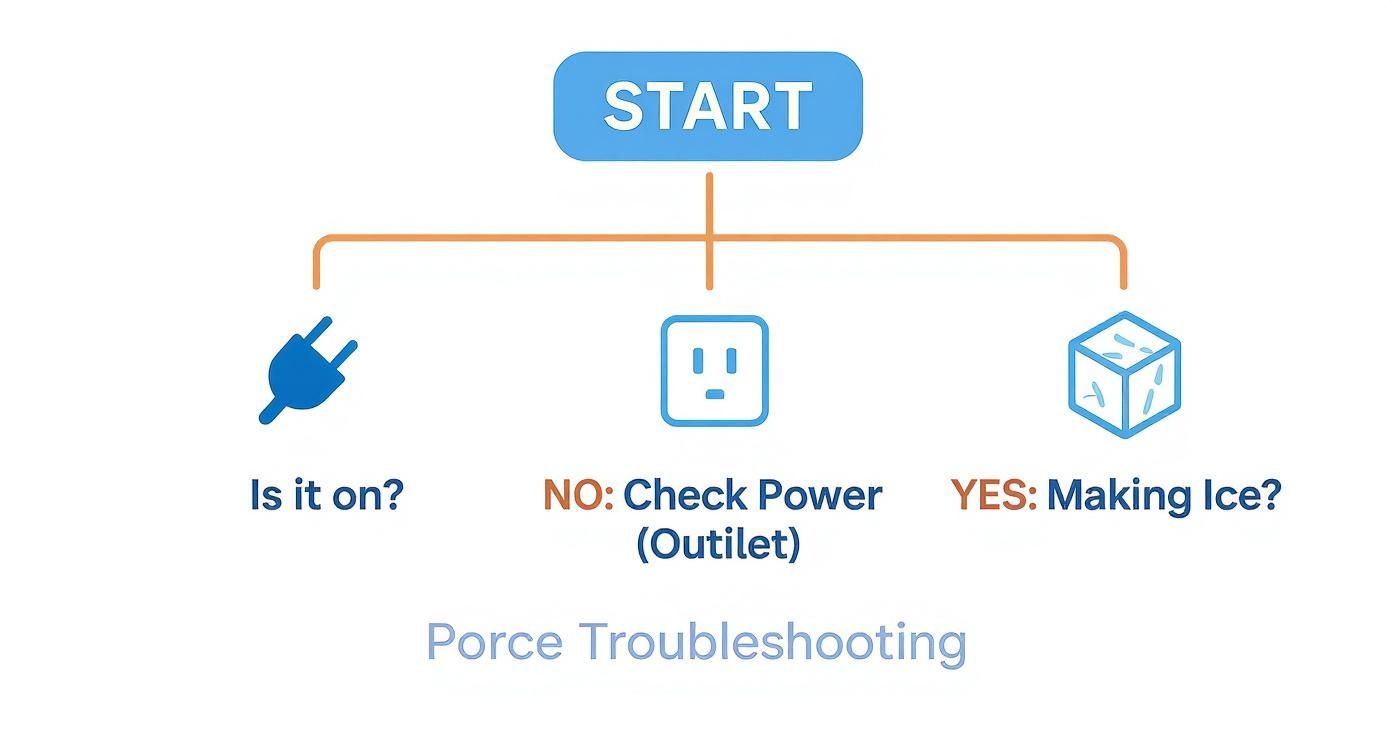

You always want to start with the basics. Don't assume the worst until you've ruled out the simple stuff. This little flowchart is a great visual guide for those first few steps in your commercial ice maker troubleshooting process.

It really just reinforces the golden rule of troubleshooting: check the power and the most obvious functions first. It can save you a ton of time and stress.

Quick Diagnosis Checklist for Low Ice Production

To help your staff quickly run through the most common issues, we put together a simple checklist. This table moves from the easiest external checks to slightly more involved internal ones, giving you a logical path to follow when the ice stops dropping.

| Symptom | Potential Cause | Simple Fix to Try First |

|---|---|---|

| Machine is completely off | No power | Check if it's plugged in securely. Test the outlet with another device. Check the circuit breaker. |

| Machine runs, but no ice | No water | Verify the main water shut-off valve behind the unit is fully open. Check the water line for kinks. |

| Ice production is very slow | Clogged water filter | If it's been over 3-6 months, swap it out. Hard Las Vegas water clogs filters fast. |

| Small or misshapen ice | Low water flow or hot environment | Check the filter first. Then, ensure the machine has at least 6 inches of clearance for airflow. |

| Machine runs constantly, gets hot | Dirty condenser coils | Visually inspect the coils. If they're covered in dust/grease, they need a good cleaning. |

This table isn't exhaustive, but it covers the vast majority of "no ice" calls we see. Running through these steps can often solve the problem in minutes without needing to call a professional.

The Impact of Las Vegas Heat on Your Ice Machine

Living and working in the desert means heat is always a factor. Commercial ice makers are essentially refrigerators, and their whole job is to pull heat out of water. When your kitchen temperature climbs to 90°F or higher, that air-cooled machine has to work overtime just to keep itself cool, let alone freeze water. This extra strain directly causes slower production and often results in smaller, slushier cubes.

Make sure your machine can breathe. It needs at least six inches of clearance on all sides for proper airflow. A unit shoved into a tight, hot corner is just asking for trouble.

Pro Tip: On those brutally hot summer days, try pointing a small shop fan at the machine’s intake vents. That little bit of extra airflow can sometimes be enough to give it the boost it needs to keep up.

Water Supply and Filtration Issues

No water, no ice. It's that simple. Your machine is completely dependent on a steady, clean stream of water, and any hiccup in that supply will bring production to a dead stop. This is one of the first places I look when a machine is running but the bin is empty.

Start by looking at the water line connected to the back of the unit. Is it kinked or crushed against the wall? I’ve seen this happen countless times, and simply pulling the machine out an inch can solve the problem instantly.

Next, look at the water filter. Here in Las Vegas, our water is packed with minerals. That "hard water" is brutal on filters, clogging them up way faster than you'd think. A clogged filter is like a blocked artery for your ice machine—it starves it of the water it needs to function.

Here’s a quick water-check routine:

- Is the Valve Open? Follow the line back to the wall and make sure the water supply valve is turned all the way on.

- When Was the Filter Changed? If you can't remember, it's overdue. In a busy Las Vegas spot, filters need to be changed every 3-6 months, period.

- Any Drips? Check all the connections for leaks. A slow drip can reduce pressure and cause problems over time.

This isn't just an ice machine issue, either. All of your essential restaurant equipment, from commercial freezers to refrigerators, operates better with proper maintenance and in the right environment.

Diagnosing Internal Component Problems

Okay, so the room isn't an oven and you've confirmed you have strong water pressure right up to the machine. Now it’s time to think about a couple of common internal parts that can fail: the water inlet valve and the condenser coil.

The water inlet valve is what the machine uses to let water in for a harvest cycle. It's controlled electronically. If the valve is working, you can usually hear a distinct "click" followed by a humming sound as water flows in. If that part of the cycle is dead silent, the valve itself might have failed.

The condenser coil is even more critical. Its job is to vent all the heat that the machine pulls out of the water. In a kitchen environment, these coils get caked with grease, dust, and grime. When they're dirty, they can't get rid of the heat, forcing the whole system to work harder and run longer. This absolutely tanks your ice production.

Cleaning the condenser is a simple bit of maintenance that pays huge dividends. Just grab a stiff brush and a vacuum to carefully clean the fins. Restoring proper airflow can often bring a struggling machine right back to life. It's a key part of any good equipment maintenance plan.

Decoding Leaks, Odd Ice Shapes, and Strange Noises

Sometimes, the most baffling problems aren't a total lack of ice. Instead, it's the weird little symptoms that leave you scratching your head. A sudden puddle on the floor, cloudy or hollow ice, or a machine that starts making new and alarming noises can be just as disruptive as a full-on breakdown. This is where your commercial ice maker troubleshooting skills really get tested.

Think of these issues as the machine's way of telling you something specific is wrong before it becomes a catastrophic failure. Learning to read these signals, especially in the demanding environment of a Las Vegas kitchen, is the key to staying ahead of major repair bills. Let's break down what these symptoms mean and what you can actually do about them.

Finding the Source of Water Leaks

Seeing a pool of water spreading out from your ice machine is an immediate red flag. Before you do anything else, shut off the water supply to the unit and unplug it. Water and electricity are a dangerous mix, and safety has to come first.

Once the machine is safe to approach, you can start playing detective. Most leaks come from a few usual suspects:

- Clogged Drain Line: This is, by far, the most common culprit. Over time, slime and gunk can build up in the drain hose, causing water from the melting cycle to back up and spill over.

- Cracked Water Trough: This part distributes water over the evaporator plate. If it develops a crack, water will leak out, often dripping right into the bin or onto the floor.

- Loose Fittings: Check the water inlet connection at the back of the machine. The constant vibration of the unit can sometimes loosen these fittings, causing a slow but steady drip.

- Damaged Bin Drain: The drain at the bottom of the ice bin can also get clogged or cracked, which means you'll find a puddle directly on the floor.

A clogged drain is usually an easy fix with a stiff brush and some cleaner. But if you spot a crack in a major component like the water trough, that’s a clear sign you’ll need to order a replacement part.

Why Your Ice Looks So Strange

The quality of your ice says a lot about the health of your machine. Here in Las Vegas, we're known for our extremely hard water, which is the primary enemy of clear, solid ice. When a customer gets a drink filled with cloudy, small, or hollow cubes, it just doesn't look good.

A quick look at local water quality reports shows that Las Vegas has some of the hardest water in the nation, with levels often topping 280 parts per million (PPM). That high mineral content, mostly calcium and magnesium, is what causes scale to build up so quickly inside ice machines.

This mineral buildup, or scale, forms an insulating layer on the evaporator plate where the ice is made. This layer messes with the freezing process, leading to all sorts of poorly formed ice. If your machine is producing anything other than its usual perfect cubes, scale is almost always the reason. A thorough descaling and cleaning cycle is the only real fix.

What Those Noises Are Really Telling You

A commercial ice machine has a predictable rhythm—the hum of the compressor, the sound of water flowing, and the clatter of ice dropping into the bin. When you start hearing a new, unusual noise, pay attention. It's an audible clue that a component is on its way out.

Here’s a quick guide to translating your machine's new vocabulary:

- Grinding or Squealing: This often points right to a problem with the water pump or another motor. The bearings might be failing, which needs immediate attention before the whole motor seizes up.

- Loud Banging During Harvest: A loud thud when the ice drops can mean an issue with the harvest-assist mechanism. It can also mean the ice slab is sticking to the evaporator plate because of, you guessed it, scale buildup.

- Constant Clicking: This could be a faulty relay or a control board trying and failing to kick off a cycle. This is usually an electrical issue that’s best left to a professional.

- High-Pitched Whining: This can sometimes signal a refrigerant leak or a compressor that is under serious strain. This is a big deal, and you should shut the machine down immediately.

Ignoring these sounds is just asking for trouble. A failing pump can quickly cause more expensive damage to other parts. Shutting the machine down to investigate a strange noise is always the smart move and can prevent a minor issue from taking down other essential equipment, like your commercial refrigerators or freezers that might share the same circuit. For any bar or restaurant, keeping a reliable set of ice machines running is absolutely critical for success.

Building a Proactive Maintenance Routine That Works

The best way to fix a problem is to make sure it never happens in the first place. While it's good to know what to do when your ice machine sputters to a halt, a solid maintenance plan is what really separates the pros from the panicked. For any busy Las Vegas restaurant, this isn't just about cleaning—it's an investment that prevents costly emergency calls, adds years to your equipment's life, and guarantees your ice is always top-quality.

A great routine doesn't need to be complicated. It’s all about creating simple, repeatable habits for your team and scheduling the bigger, more technical jobs on a regular basis. This approach flips commercial ice maker troubleshooting from a reactive headache into a controlled, preventative habit.

Your Essential Maintenance Checklist

The secret to a routine that actually sticks is breaking it down into daily, weekly, and monthly tasks. This way, maintenance never feels like a massive, disruptive project. It also empowers your staff to take ownership of the machine's health—a mindset that benefits all your equipment, from your ice machine to your commercial refrigerators and freezers.

Daily Habits (Under 2 Minutes)

- Wipe Down Exterior Surfaces: Grab a food-safe sanitizer and clean the outside, especially the door handle and the ice scoop.

- Check the Ice Bin: Give the bin a quick scan. Scoop out any debris and make sure the scoop is in its holder, never left in the ice.

- A Quick Listen and Look: Take a second to listen for odd noises. A quick glance around the base can catch small drips before they become puddles.

Weekly Tasks (5-10 Minutes)

- Inspect the Air Filter: If your unit has a removable air filter, pull it out for a cleaning. A clogged filter is like trying to breathe through a straw—it forces the machine to work way too hard.

- Check Water Filter Date: Find the date on your water filter cartridge. If it’s getting close to its 3-6 month replacement window, make a note to order a new one.

- Sanitize the Bin and Scoop: Empty the ice bin and give it a thorough wipe-down with an approved sanitizing solution.

This simple schedule is your first line of defense, catching the small stuff before it snowballs.

The Semi-Annual Deep Clean and Sanitization

Twice a year, your ice machine needs a full-on deep clean. This is the single most important thing you can do for it. Here in Las Vegas, our hard water means scale buildup is a given. A semi-annual descaling and sanitizing cycle is non-negotiable for performance and food safety.

This process uses two distinct chemical solutions: one to dissolve mineral scale and another to eliminate bacteria and slime.

Important Safety Note: Never, ever mix descaler and sanitizer. You must run a full rinse cycle after using the descaler and before adding the sanitizer. Mixing these chemicals can create a dangerous reaction.

This is also the perfect time to give the condenser coils a good cleaning so the machine can properly dissipate heat. For a more detailed walkthrough, check out our guide on commercial ice maker maintenance.

How Maintenance Directly Hits Your Bottom Line

Let's be clear: this isn't just about avoiding repairs. It's about money. Most of the time, troubleshooting a commercial ice maker is a direct result of neglect. The numbers don't lie—scale-related problems, which are totally preventable, can cut a machine's ice production by up to 20%. That forces it to run longer and burn more electricity just to keep up.

Newer ice machines are impressively efficient, often using up to 30% less energy than older units. But you only get those savings if the machine is running correctly. Keeping up with maintenance ensures all your essential restaurant equipment is pulling its weight, reliably, day after day.

Knowing When to Call a Las Vegas Repair Technician

While this guide gives you the confidence to tackle many common ice machine hiccups, one of the smartest moves you can make is knowing your limits. Some problems go beyond a simple fix; they can be downright dangerous for anyone who isn't a trained pro. Spotting these red flags is key to keeping you, your staff, and your expensive equipment safe—including the commercial refrigerators and freezers that might be sharing the same electrical circuit.

Trying to DIY a major electrical or sealed-system repair can end in serious injury, instantly void your warranty, or turn a simple fix into a total unit replacement. In the fast-paced Las Vegas restaurant scene, the cost of a professional service call is nothing compared to the price of a catastrophic failure during a dinner rush.

Electrical System Failures

If you even suspect a problem with the machine's core electrical guts, it’s time to stop what you're doing and pick up the phone. These are not user-serviceable parts, and the risk is just too high.

Here are the big electrical red flags:

- A Dead Control Board: The display is dark, but you’ve already confirmed the outlet is working. This usually points to a fried main control board.

- Burnt Wires or Smell: That distinct, acrid smell of burning electronics is an unmistakable sign to unplug the unit immediately and call for backup.

- Tripping Breakers Repeatedly: If the machine trips its circuit breaker every time it tries to start, you could be looking at a major short circuit in a component like the compressor.

These symptoms signal deep-seated issues that demand specialized diagnostic tools and a pro’s understanding of high-voltage systems.

Refrigerant System Complications

The refrigerant system is the sealed, high-pressure heart of your ice machine. It's also a hands-off zone. By law, only EPA-certified technicians are legally allowed to handle these systems. Messing with refrigerant without the right certification is not only illegal but extremely hazardous.

Never, ever try to diagnose or fix a refrigerant issue yourself. Refrigerant can cause severe frostbite on contact and is an environmental hazard if it leaks. This is a hard line in the sand—always call a certified professional.

Get a technician on the phone right away if you see:

- Visible Oily Residue: A refrigerant line leak often leaves a tell-tale greasy film around fittings or on the coils.

- Hissing Sounds: Any kind of hissing when the machine should be quiet is a classic sign of escaping refrigerant gas.

- Compressor Not Running: If that big, black tank-like component isn't running but feels hot to the touch, it’s a sign of a serious internal failure.

The Rise of Smart Technology and Predictive Maintenance

The good news is that the industry is getting smarter about preventing these emergencies in the first place. The integration of IoT (Internet of Things) features is a game-changer, enabling predictive maintenance alerts that have been shown to cut down on emergency repair calls by 25-40%. This tech helps you see a failure coming before it knocks you out of service—a massive advantage in a 24/7 town like Las Vegas.

At the end of the day, knowing when to call for help is the mark of a savvy operator. For the really tough issues, or anytime you're in doubt, the expert technicians in Las Vegas have the right tools and training to get your machine back online safely. And when the time comes for a new machine, exploring the different types of ice maker Las Vegas businesses depend on will help you find the perfect fit for your operation.

Common Ice Machine Questions from Las Vegas Restaurateurs

Working with restaurants and bars all over Las Vegas, we tend to hear the same questions over and over. When an ice machine acts up, you need answers fast. Think of this as a rapid-fire Q&A, hitting the most common concerns we hear about ice machines trying to survive in our unique desert climate.

How Often Should I Really Clean My Ice Machine in Las Vegas?

With our city's notoriously hard water and the relentless demand of a busy kitchen, a full deep clean and sanitization is non-negotiable at least every six months. I can't stress this enough—it's the absolute baseline for keeping your machine from giving you headaches.

Now, if you're a high-volume bar or a spot with a lot of yeast floating around (think pizzerias), we strongly recommend bumping that up to a quarterly schedule. Your water filters are your first line of defense here. Give them a look monthly and plan on swapping them out every 3-6 months, depending on your water quality and how hard you're pushing the machine.

For any Las Vegas establishment, that six-month cleaning schedule is the bare minimum. Skipping it is almost a guarantee you'll be calling for service due to scale buildup, which is one of the most common triggers for commercial ice maker troubleshooting calls we get.

Why Did My Ice Suddenly Go Cloudy?

Cloudy ice is a dead giveaway that your water has impurities. The number one culprit, by a long shot, is a spent water filter that’s no longer pulling dissolved minerals out of the water. Picture a sponge that’s totally soaked—it just can't absorb anything else.

It can also be a sign of scale buildup on the evaporator plate itself. That scale messes with the freezing process and traps tiny air bubbles in the ice cubes. Your first move should always be to swap out the water filter. If the ice doesn't clear up in a day or two, a full descaling and cleaning cycle is your next step.

What Should I Check When The Machine Is Running but Not Making Much Ice?

Slow production is a classic problem with a few usual suspects. First, feel the air around the machine. If your kitchen is hotter than a summer afternoon on the Strip, the machine is working overtime just to get rid of heat, and that directly kills ice production. Make sure you've got at least six inches of clear space on all sides for air to move.

Next, take a look at the condenser coils. If they're caked in dust and kitchen grease, they can't breathe, and they can't release heat. A good cleaning can make a night-and-day difference. And don't forget, a clogged water filter means less water getting to the machine, which always means less ice coming out.

Air Cooled or Water Cooled for Las Vegas?

This is a big one for our climate. An air-cooled machine uses a fan to blow air over its condenser, while a water-cooled one uses a constant stream of water.

- Air-cooled machines are generally more energy-efficient and way more common. The downside? They struggle in extreme heat and will pump more hot air into an already sweltering kitchen.

- Water-cooled units are champs in high-temp environments, but they use a ton of water—a huge factor to consider here in the desert.

For most businesses in town, a properly placed and well-ventilated air-cooled machine is the smarter, more economical choice. But it’s always a good idea to get a pro's opinion on your specific kitchen layout. All your essential equipment, from your commercial refrigerators to your workhorse ice machine, needs to be the right fit for Vegas.

When you've troubleshot all you can and realize it's time for an upgrade, Las Vegas Restaurant Equipment has your back. We carry a curated selection of new, warranty-backed ice machines, commercial refrigerators, and commercial freezers built to handle the heat of a Las Vegas kitchen. Check out our inventory and get reliable equipment with fast, free shipping at https://lasvegasrestaurantequipment.com.