From perfectly crispy appetizers to the late-night comfort food your customers crave, a reliable commercial deep fryer is the unsung hero of your restaurant's most profitable dishes. This isn't just another piece of equipment; it's a core investment that has a direct say in your food quality, kitchen speed, and ultimately, your bottom line.

Thriving in the Las Vegas Food Scene

Vegas never sleeps, and neither can your kitchen. The culinary scene here is a high-stakes, fast-paced world, stretching from five-star dining on the Strip to packed downtown spots and nimble food trucks. This vibrant city offers a diverse array of restaurants that cater to every palate, meaning the competition is fierce, and your success hinges on being consistent and fast, every single shift.

The 24/7 grind of Las Vegas puts every piece of gear to the test. A commercial deep fryer drives a huge portion of many menus, but it can't do the job alone. It’s part of a bigger kitchen ecosystem, a workhorse that needs the right teammates to keep the line moving.

In a high-volume market like Vegas, success is all about the synergy between your core appliances. A dependable fryer is only as good as the cold storage keeping its ingredients fresh and the ice machine keeping up with the drink orders.

Building Your Kitchen Foundation

To build a kitchen that can handle the Vegas rush, you have to think about how your main tools work together. The link between your cooking equipment and your cold storage is absolutely critical for a smooth workflow and bulletproof food safety. This essential restaurant equipment is the foundation for success. Think of it like an assembly line—each station has to support the next, or the whole thing grinds to a halt.

This foundational setup usually includes:

- Commercial Refrigerators: These are essential for keeping produce, proteins, and sauces at safe temps. Every ingredient hitting that hot oil needs to be fresh and ready to go.

- Commercial Freezers: In a city that demands huge output, commercial freezers aren't a luxury. They're vital for stocking bulk items like fries, appetizers, and proteins, which helps you minimize waste and ensures you never 86 an item during a dinner rush.

- Ice Machines: With the desert heat, a high-capacity ice machine is a must-have for any bar, restaurant, or hotel. It’s a small detail that has a massive impact on customer satisfaction.

Picking the right commercial deep fryer is a huge first step, but seeing its place in the bigger picture is the real key to building a tough, profitable operation. This guide will walk you through everything you need to know—from power types and sizing to local codes and upkeep—so you can make a smart investment that’s built for the unique challenges of the Las Vegas market.

Gas vs Electric and Floor vs Countertop Fryers

Choosing your commercial deep fryer is one of the first big decisions you'll make when outfitting a new kitchen. Think of it like picking the engine for a race car—your choice between gas and electric power, and a floor-standing or countertop model, will set the pace for your kitchen's speed, efficiency, and overall flow. This is especially true in a relentless market like Las Vegas.

The power source is the heart of the machine. Gas and electric fryers each have their own set of strengths, and understanding them is key to matching the right fryer to your menu and expected volume.

The Powerhouse Debate: Gas Versus Electric

When it comes to raw power, gas fryers are the undisputed champions. Their output is measured in BTUs (British Thermal Units), and they heat up incredibly fast. More importantly, they have a lightning-fast recovery rate—that’s the time it takes for the oil to get back to the perfect temperature after you drop in a basket of frozen fries. For any spot on the Las Vegas Strip facing a non-stop dinner rush, that kind of speed is a must-have.

Electric fryers, on the other hand, are all about precision. Their power, measured in kilowatts (kW), comes from heating elements submerged right in the oil. This setup gives you incredibly consistent and even heat, which is perfect for more delicate items like tempura, doughnuts, or anything else where exact temperature control makes or breaks the final product.

Deciding between gas and electric often comes down to your kitchen's existing setup and your menu's demands. Here's a quick breakdown to help you weigh the options.

| Feature | Gas Deep Fryer | Electric Deep Fryer |

|---|---|---|

| Heating Speed | Very fast initial heat-up and recovery. | Slower initial heat-up but excellent temperature stability. |

| Power Source | Requires a natural gas or propane line. | Requires a dedicated high-voltage electrical circuit. |

| Best For | High-volume kitchens frying basics like fries, wings, and chicken. | Kitchens cooking delicate items or lacking gas hookups. |

| Installation | More complex, often requiring professional gas line installation. | Simpler installation, essentially a "plug-and-play" setup. |

| Energy Cost | Generally lower operating costs due to cheaper natural gas. | Typically higher utility costs, but more energy-efficient. |

Ultimately, a high-volume kitchen pumping out fried chicken and french fries will almost always lean toward gas. A smaller cafe or a kitchen focused on specialty items might find the precision of an electric model is a better fit.

Footprint and Workflow: Floor Models Versus Countertop Units

Beyond the power source, the fryer's physical size shapes how it fits into your kitchen's daily grind. This choice is a classic balancing act between your output needs and your available space—a challenge familiar to every kind of restaurant in Las Vegas, from tiny food trucks to sprawling casino kitchens.

Floor-model fryers are the industry workhorses, built from the ground up for serious volume. With large oil capacities, usually in the 40-75 lbs range, they are made to handle continuous service without breaking a sweat. If fried food is a star on your menu, a floor model is the standard for a reason.

Countertop fryers bring amazing flexibility to the table, especially for smaller operations. They’re the perfect solution for a bar looking to add an appetizer menu, a food truck with limited room, or even a large kitchen that needs a dedicated fryer for something specific like gluten-free items. Their output is lower, but their small footprint and portability are major advantages.

The choice between a floor or countertop commercial deep fryer isn't just about size; it's a strategic decision based on menu, customer volume, and kitchen layout. The right choice prevents bottlenecks and maximizes every square inch of your workspace.

The fryer market is always changing as chefs and owners look for better ways to speed up service and save on oil costs. In fact, the specialty commercial fryer market is projected to grow from USD 1.3 billion in 2025 to USD 2.5 billion by 2035. A big part of that growth is in new heating designs, with tube-and-baffle systems expected to make up over 42% of revenue by 2025 because they heat so evenly. This shows a clear industry trend toward more efficient and specialized gear. You can explore more about these market trends and their impact on future equipment choices to stay ahead of the curve.

Matching Fryer Size and Specs to Your Menu

Okay, so you’ve narrowed it down between gas or electric and a floor or countertop model. That’s a great start. But now we get into the nitty-gritty—the technical specs that will make or break your fryer's performance during a chaotic dinner rush. These numbers aren't just filler on a product page; they’re the blueprint for your kitchen’s entire fried food program, dictating speed, quality, and consistency. For any operator trying to make it in a place as demanding as Las Vegas, getting these specs right is everything.

The first number people usually look at is oil capacity, measured in pounds (lbs). This is simply how much oil the vat holds, which can range from a small 30 lbs unit up to a monster 75+ lbs floor model. While it’s tempting to think bigger is always better, that’s not the whole story. The real secret to that perfect, crispy-but-not-greasy result lies in a completely different metric.

Understanding the Critical Role of Recovery Rate

If there's one spec you absolutely cannot ignore, it's the recovery rate. This is the single most important performance indicator of any commercial fryer. It tells you how fast the oil can get back to its ideal cooking temperature after you drop in a basket of frozen food.

Picture this: you dump a batch of frozen fries into 350°F oil. That oil temperature immediately crashes. A fryer with a slow recovery rate will struggle to climb back up, leaving your food to soak in lukewarm oil. The result? Soggy, greasy garbage that no customer will ever come back for.

A fast recovery rate is what separates a beautiful, golden-brown product from a sad, limp one. In a town like Vegas where the pace never lets up, a slow fryer creates a bottleneck that can grind your entire line to a halt. This is where high-performance units, especially powerful gas models with high BTUs, really shine. They ensure that every single batch of fries that comes out of the kitchen is just as crisp as the last, even when you're slammed.

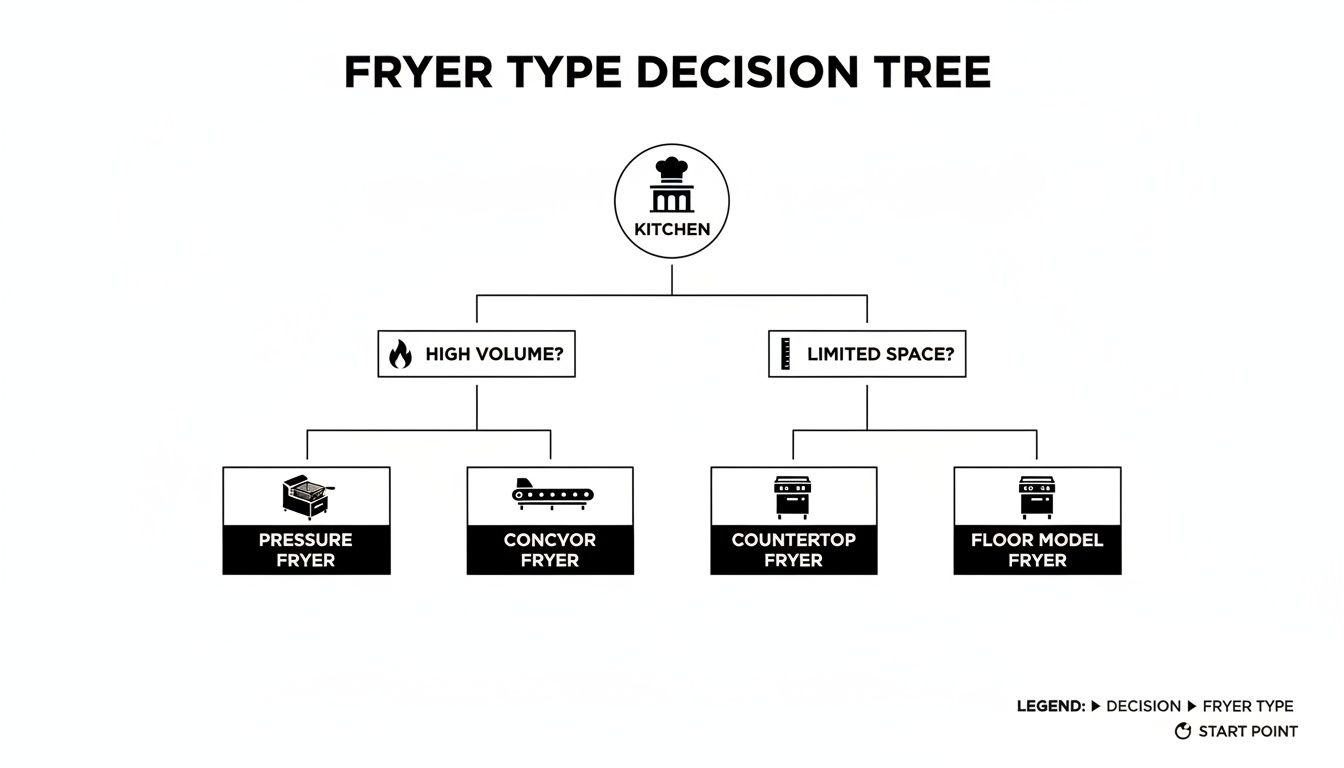

This decision tree can help you visualize how your kitchen's unique needs—like crazy high volume or a tight footprint—should guide your initial choice.

As the graphic shows, if you’re running a high-volume operation, you should be looking at floor models. If you’re squeezed for space, countertop units are your best bet. It’s a simple way to get pointed in the right direction from the start.

Calculating Your Production Needs

To make sure you’re buying the right tool for the job, you need to connect its specs to what you’ll actually be cooking. A solid rule of thumb is that a standard fryer can produce roughly twice its oil capacity in pounds of frozen french fries per hour.

Let’s run the numbers for a busy spot on Fremont Street:

- Fryer Model: A standard 50 lb floor model.

- Estimated Output: 50 lbs (oil capacity) x 2 = 100 lbs of fries per hour.

If your projections show you'll sell 80 lbs of fries during your peak hour, this fryer is perfect—it gives you plenty of power with a comfortable cushion. But if you think you’ll be pushing 120 lbs an hour, that single fryer is going to become your biggest headache. In that case, you'd need to either level up to a larger model or, better yet, add a second unit to keep things moving smoothly. A little bit of math upfront will save you from a world of hurt later.

Matching your fryer’s output to your menu's peak demand is one of the smartest things you can do to prevent kitchen backups and keep food quality high. Don't eyeball it—use the numbers to make a decision that will support your entire crew.

The Advantage of Split-Pot Fryers

For kitchens with diverse menus, a split-pot fryer can be a game-changer. These fryers have a divided vat, essentially creating two smaller, independent frying stations in one machine. The biggest advantage here is preventing flavor transfer. You can fry up breaded onion rings in one side and delicate fish fillets in the other without the tastes bleeding into each other. No one wants fishy-tasting onion rings.

This is especially handy for ghost kitchens or big Strip restaurants that cater to a huge variety of tastes and need to be mindful of allergens. Plus, during slower shifts, you can fire up just one side of the fryer, which is a great way to save on both oil and energy costs. It's a versatile piece of equipment that adds a ton of flexibility—something every Las Vegas kitchen needs.

Installation, Ventilation, and Safety Compliance

Choosing the perfect commercial deep fryer is only half the battle. Getting it installed correctly and safely is where your investment truly pays off. Here in Las Vegas, with our strict safety codes and kitchens that never stop, a proper installation isn't just a suggestion—it's the only way you'll pass inspection and protect your business.

One mistake can lead to crippling fines, a forced shutdown, or worse, a devastating fire. This is especially true in Clark County, where health and safety inspectors don’t miss a thing. From the high-end spots on the Strip to the bustling kitchens in Henderson, every single detail of your setup matters. It's way more than just plugging in a machine; it's a careful process of handling ventilation, utilities, and all the right certifications.

The Unbreakable Rule of Proper Ventilation

A commercial deep fryer throws off an incredible amount of heat and grease-filled vapor. Without the right ventilation, that greasy air coats every single surface in your kitchen, creating a massive fire hazard and a gross, unhealthy place to work.

This is why a Type 1 commercial kitchen hood is completely non-negotiable.

Unlike a basic vent, a Type 1 hood is engineered specifically to capture and exhaust grease, smoke, and intense heat. It's your number one defense against kitchen fires. These hoods must also be paired with an integrated fire suppression system—you’ll often hear it called an Ansul system—that automatically blasts fire-retardant chemicals if a fire breaks out. This one-two punch is mandatory for operating a fryer legally and safely.

Decoding NSF and ETL Certifications

When you're shopping for equipment, you'll see stickers for NSF and ETL. These aren't just brand names; they are seals of approval that a health inspector will look for the second they walk through your door. Think of them as a passport for your gear, proving it’s built for the rigors of a commercial kitchen.

- NSF (National Sanitation Foundation): This certification guarantees the fryer is designed and built to be easily cleaned and sanitized, which is critical for preventing foodborne illness.

- ETL (Intertek Testing Services): This mark shows the fryer meets North American safety standards for either gas or electrical equipment, protecting you from fire and electrical shock hazards.

A commercial fryer without both NSF and ETL stamps is a dead end. It will not pass a health inspection in Las Vegas. Checking for these marks before you buy will save you the nightmare of having to rip out and replace brand-new, non-compliant equipment.

Utility Connections and Safety Clearances

Hooking up your fryer to gas or electric lines is a job for licensed pros, period. For a gas fryer, a professional will make sure the gas line is the right size to deliver consistent pressure and that every connection is tight and leak-free. For electric models, you need a dedicated circuit with the correct voltage and amperage to avoid dangerous electrical overloads.

Just as important is giving your fryer room to breathe. The manufacturer's manual will tell you the exact minimum distance required between the fryer and any walls or other equipment. That clearance is vital for preventing heat from building up and potentially igniting nearby surfaces.

Understanding the broader commercial property fire safety regulations is a must for keeping your installation and day-to-day operations safe. Don't forget that managing the used oil and grease is also a big part of staying compliant; our guide on grease trap sizing can help you make sure your whole system is up to code. Following these rules isn't just about passing an inspection—it's about building a kitchen that's fundamentally safe from day one.

Smart Maintenance and Oil Management Strategies

Your commercial deep fryer is a true workhorse, but like any piece of high-performance machinery, it needs consistent care to pump out the crispy, golden food your customers crave. Smart maintenance isn't just about a quick wipe-down at the end of the night; it's a game plan to protect your investment, keep your food quality high, and sidestep costly, kitchen-halting breakdowns.

For a Las Vegas kitchen that runs 24/7, a well-cared-for fryer is the thin line between a smooth, profitable service and absolute chaos. This kind of proactive thinking is crucial in the cutthroat Vegas hospitality world. The city's sheer density of restaurants, bars, and casinos drives insane demand for reliable equipment. Data from across the country shows that fryer demand is always hottest in concentrated markets just like ours.

One forecast predicts the global commercial deep fryer market will jump from USD 504.01 million in 2025 to USD 868.37 million by 2033. The North American slice of that pie alone is expected to hit over USD 287.84 million by 2032. For those of us operating in Nevada, this just reinforces how important it is to manage our equipment for the long haul. You can dig deeper into these industry trends in this detailed market research report.

Mastering Oil Management to Cut Costs

Let's be real: cooking oil is one of the biggest, most persistent expenses tied to your fryer. If you treat it like a disposable commodity, you're just watching your profit margins shrink. The secret to saving serious cash is simple: extend the life of your oil with a consistent filtration schedule.

Think about it this way: unfiltered oil is like running a car engine without an oil filter. All those tiny bits of food, breading, and sediment break off, sink to the bottom, and burn. This turns your oil dark, smoky, and rancid. This process, called oil degradation, doesn't just make your food taste bad—it forces you to dump expensive oil way more often than you should.

A daily filtration routine, usually done at closing, slows this breakdown dramatically. It gets all that gunk out, keeping your oil cleaner and fresher for longer.

Making daily oil filtration a habit can slash your cooking oil expenses by up to 50%. For a busy restaurant, that simple routine can add up to thousands of dollars in savings a year, going straight to your bottom line.

Your Daily, Weekly, and Monthly Maintenance Checklist

Staying on top of maintenance is all about consistency. When you break it down into a simple schedule, it’s easy to make sure nothing gets missed. A solid cleaning routine is the perfect place to start, and for the nitty-gritty, check out our guide on how to clean a commercial deep fryer.

Here’s a straightforward maintenance schedule you can put into action today:

-

Daily Tasks:

- Filter the Oil: This is non-negotiable. Filter your oil at the end of every single day to pull out all the food debris.

- Wipe Down Exterior: Give the outside of the fryer a good cleaning to get rid of grease and splatters.

- Clean Baskets: Scrub the fryer baskets to stop that nasty carbon from building up.

-

Weekly Tasks:

- Perform a Boil-Out: Drain the old oil and give the fry pot a deep clean with a specialized cleaning solution and hot water. This tackles the hardened grease that daily wiping just can't handle.

- Calibrate Thermostat: Use a good thermometer to check if your fryer’s thermostat is accurate. You need to know it's heating to the right temperature.

Troubleshooting Common Fryer Issues

Even with the best maintenance plan, things can still go wrong. Knowing how to spot and fix common problems can save you a service call and keep the kitchen from grinding to a halt.

Problem 1: The Pilot Light Won't Stay Lit (Gas Fryers)

This is a classic issue with gas fryers. The first thing you should always check is the thermopile. It’s a safety sensor that cuts the gas if the pilot flame goes out. Sometimes it's just dirty or has been knocked out of position. A gentle wipe with a soft cloth or a slight adjustment to make sure the flame is hitting the tip is often all it takes to fix it.

Problem 2: The Fryer Isn't Reaching Temperature

If your fryer is taking forever to heat up or just won't get hot enough, you might have an issue with the heating elements (on electric models) or the thermostat. First, double-check that the thermostat is set correctly and wasn’t accidentally bumped to a lower setting. If that’s not the problem, it could be a sign that a component is failing and it’s time to call in a pro.

Finding the Right Equipment Supplier in Las Vegas

Picking out the perfect commercial deep fryer is a huge win, but it's only half the battle. The final, and arguably most important, piece of the puzzle is deciding where to buy it from. In a town like Las Vegas, where downtime is the absolute enemy, your equipment supplier isn't just a vendor. They're a critical partner in your restaurant's survival and success.

Working with a local or regional supplier who actually gets the Nevada market gives you an edge that a faceless national chain just can't compete with.

The culinary scene here runs at a breakneck pace, whether it's in a massive casino or a cozy neighborhood spot. When a money-maker like your fryer goes down, you don't have a week to wait for a replacement. Every single hour the fryer is cold, you're losing money. This is where a supplier with a nearby warehouse becomes your best friend, offering shipping that gets your kitchen back up and running in a day or two, not a week.

Equipment Picked for the Desert Climate

A smart supplier also knows the unique pain of running a kitchen in the desert. Las Vegas kitchens get brutally hot, putting an incredible strain on every single appliance. A good local partner knows this and stocks their inventory accordingly, focusing on equipment built to take a beating in high-heat environments.

And it’s not just about your fryer. The whole kitchen ecosystem has to be tough. A supplier who knows Las Vegas will also stock other essential restaurant equipment built for this climate:

- Commercial Refrigerators: You need units with beefy compressors that can hold safe temps even when the kitchen feels like an oven.

- Commercial Freezers: These have to be rock-solid to protect thousands of dollars of frozen product from the relentless desert heat.

- Ice Machines: An absolute must for any bar or restaurant, these machines work overtime in Vegas and need to keep up with insane demand.

A supplier with local know-how doesn't just sell you a box; they sell you a solution. They understand that a fryer going into a Las Vegas kitchen needs to be an absolute workhorse, and it needs to be backed up by refrigeration and ice equipment that can also handle the heat.

The Financial and Practical Reality

The global market for commercial fryers shows just how high the stakes are. It was valued at a massive USD 561.63 million in 2024 and is expected to hit USD 879.88 million by 2032. North America owns the biggest piece of that pie at 38.3%, thanks to our non-stop dining culture.

For anyone running a kitchen in Las Vegas, these numbers just confirm what you already know: your fryer is a core part of your business and a serious investment that has to perform. You can dig into more of these numbers in this comprehensive industry report.

The right supplier gets this. They offer financing options to help new spots get started or established restaurants expand. By mixing fast shipping, smart equipment choices like dependable Atosa fryers, and payment plans that make sense, they clear the path for you to build a kitchen that's ready to win.

Choosing from a focused lineup of commercial fryers from a supplier who knows your city isn't just a purchase—it's the smartest final investment you can make for your business.

Frequently Asked Questions

When you're outfitting a commercial kitchen, especially in a high-stakes market like Las Vegas, a lot of questions come up. Let's tackle some of the most common things restaurateurs ask when they're picking out and running a commercial deep fryer.

How Often Should I Filter Fryer Oil?

For most busy Vegas restaurants, filtering your oil every single day is the way to go, usually right after you close up shop. If you're running a 24/7 spot on the Strip or frying up a ton of heavily breaded items, you might even need to filter it twice a day to keep things tasting right.

Filtering isn't optional—it's essential. It pulls out all those tiny food bits that break down your oil fast. Staying on top of it will make your oil last longer, keep your food crispy and clean-tasting, and can honestly save you up to 50% on your annual oil costs.

What Size Fryer Do I Need for a Small Restaurant or Bar?

The perfect size really comes down to your menu and how busy you get. If you’re a bar just adding some appetizers or a small café, a countertop fryer with a 15-30 lb oil capacity is usually a great starting point. It gives you enough power to get the job done without eating up precious floor space.

For a small, full-service restaurant, a single floor model with a 40-50 lb tank is a solid first step. Before you pull the trigger, take a hard look at your menu. If fried food is a big part of what you do, getting a properly sized floor model from day one will save you from major headaches when you get slammed.

Choosing the right size isn't just about capacity—it's about protecting your workflow. An undersized fryer will slow down your entire kitchen, while an oversized one wastes energy and oil.

Does the Las Vegas Climate Affect My Fryer Choice?

The fryer itself doesn't need to be "desert-proofed," but the scorching kitchen temps here in Vegas make a couple of things absolutely critical. First, you need a seriously powerful ventilation system to pull all that intense heat from the fryer and everything else out of the kitchen.

Second, a well-insulated fryer is a much smarter buy. It holds its temperature better, which means it isn't working as hard. That puts less stress on its parts and, just as important, on your kitchen's air conditioning. That kind of efficiency is a lifesaver when your kitchen is already battling the summer heat and you need your commercial refrigerators, commercial freezers, and ice machines running strong to get through service.

Ready to get your Las Vegas kitchen geared up for success? Las Vegas Restaurant Equipment has a hand-picked selection of high-performance commercial deep fryers, refrigerators, and more, all with fast, free shipping to the valley. Check out our inventory and build a kitchen that can take the heat at https://lasvegasrestaurantequipment.com.